Polysilicic acid aluminum sulfate flocculating agent, preparation method and application

A technology of polysilicate aluminum sulfate and flocculant, which is applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water treatment parameter control, etc., can solve the problem that cannot meet the requirements of rapid on-site treatment of waste drilling fluid, polymer silicon The synthesis process of acid aluminum iron sulfate is complex, the treatment effect of drilling waste fluid is not good, etc., to achieve the effect of good flocculation and sedimentation, tight molecular structure, and fast preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation steps of polysilicate aluminum ferric sulfate flocculant in the present embodiment are as follows:

[0032] 1) Dissolve crystalline sodium silicate in water to obtain a solution with a concentration of 0.2mol / L, quickly adjust the pH value of the solution to 6 with a volume fraction of 20% sulfuric acid, then slowly adjust to 5, and polymerize at room temperature at a stirring speed of 80r / min 10min, obtain polysilicic acid (PAS);

[0033] 2) Add crystalline aluminum sulfate and crystalline ferrous sulfate in the solution of step 1) according to the molar ratio, so that the ratio of the sum of the molar masses of Al and Fe to the molar mass of Si is 0.5, the molar mass of Al and the molar mass of Fe The ratio is 0.5, polymerized at room temperature at a stirring speed of 80r / min for 10min, and then left to mature for 28h to obtain polyaluminum ferric silicate sulfate (PAFSS).

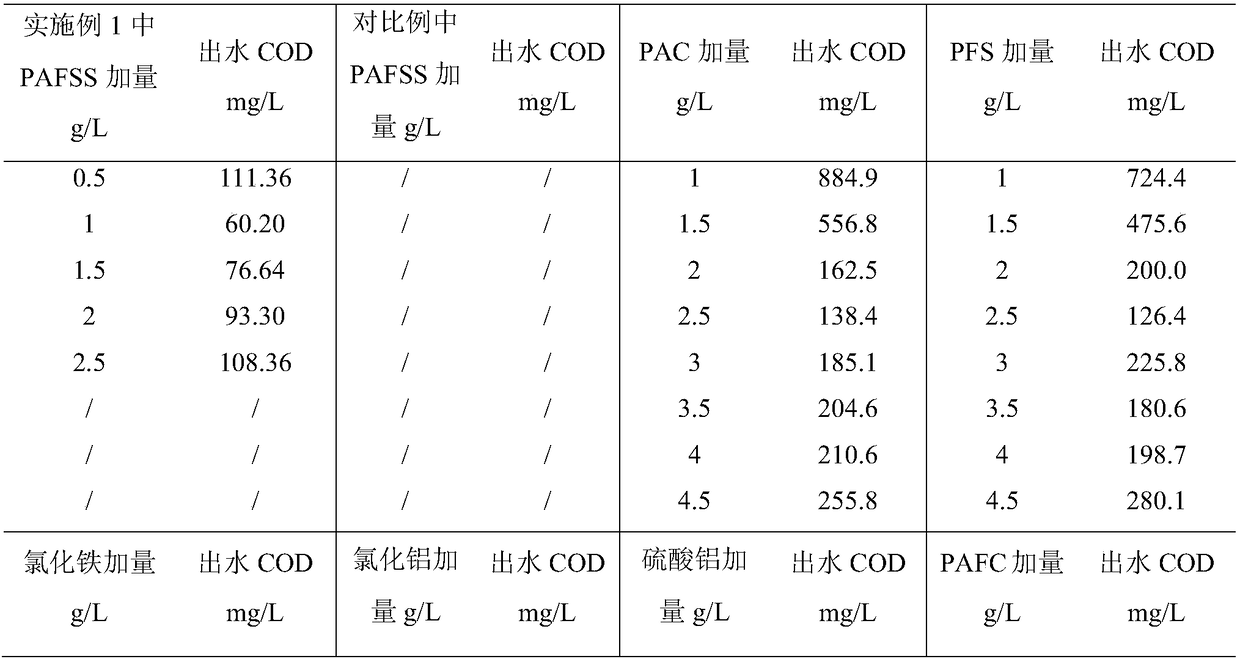

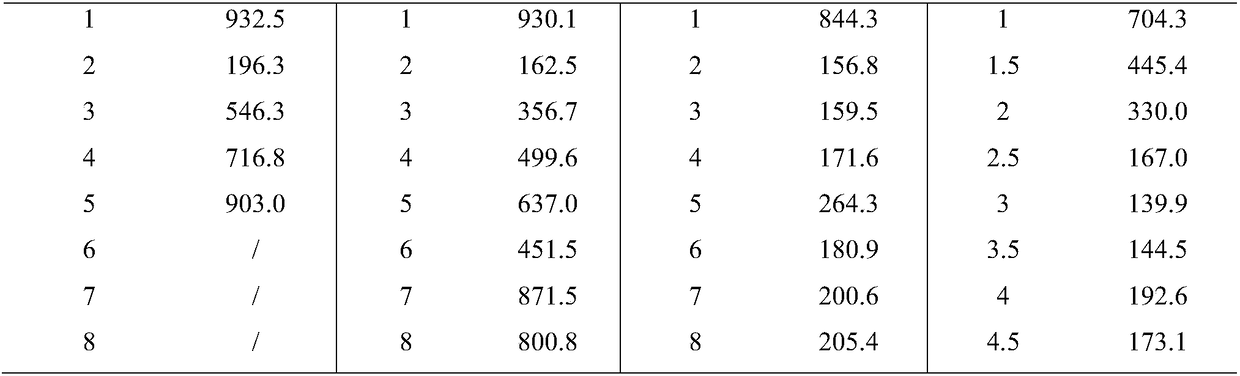

[0034] The application of polysilicate aluminum iron sulfate flocculant in t...

Embodiment 2

[0036] The preparation steps of polysilicate aluminum ferric sulfate flocculant in the present embodiment are as follows:

[0037] 1) Dissolve crystalline sodium silicate in water to obtain a solution with a concentration of 0.35mol / L, quickly adjust the pH value of the solution to 6 with a volume fraction of 20% sulfuric acid, then slowly adjust it to 3.5, and polymerize at room temperature at a stirring speed of 180r / min 20min, obtain polysilicic acid (PAS);

[0038] 2) Add crystalline aluminum sulfate and crystalline ferrous sulfate in the solution of step 1) according to the molar ratio, so that the ratio of the sum of the molar masses of Al and Fe to the molar mass of Si is 1.25, the molar mass of Al and the molar mass of Fe The ratio is 1.25, polymerized at room temperature at a stirring speed of 180r / min for 20min, and then left to mature for 24h to obtain polyaluminum ferric silicate sulfate (PAFSS).

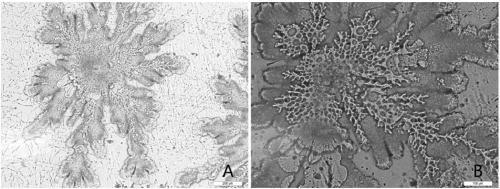

[0039] figure 1 It is the microscopic morphological characterizat...

Embodiment 3

[0042] The preparation steps of polysilicate aluminum ferric sulfate flocculant in the present embodiment are as follows:

[0043] 1) Dissolve crystalline sodium silicate in water to obtain a solution with a concentration of 0.5mol / L, quickly adjust the pH value of the solution to 6 with a volume fraction of 20% sulfuric acid, then slowly adjust it to 2.1, and polymerize at room temperature at a stirring speed of 300r / min 30min, obtain polysilicic acid (PAS);

[0044] 2) Add crystalline aluminum sulfate and crystalline ferrous sulfate in the solution of step 1) according to the molar ratio, so that the ratio of the sum of the molar masses of Al and Fe to the molar mass of Si is 2.2, the molar mass of Al and the molar mass of Fe The ratio is 2.2, polymerized at room temperature at a stirring speed of 300r / min for 30min, and then left to mature for 20h to obtain polyaluminum ferric silicate sulfate (PAFSS).

[0045] The application of polysilicate aluminum iron sulfate floccula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com