Polymeric aluminum ferric chloride-polydimethyldiallylammonium chloride composite coagulant and preparation method thereof

A technology of polydimethyl diallyl ammonium chloride and dimethyl diallyl ammonium chloride, which can be used in flocculation/sedimentation water/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. High cost of chemicals, poor water treatment effect, etc., to achieve the effect of good water treatment effect, excellent coagulation performance, and large alum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

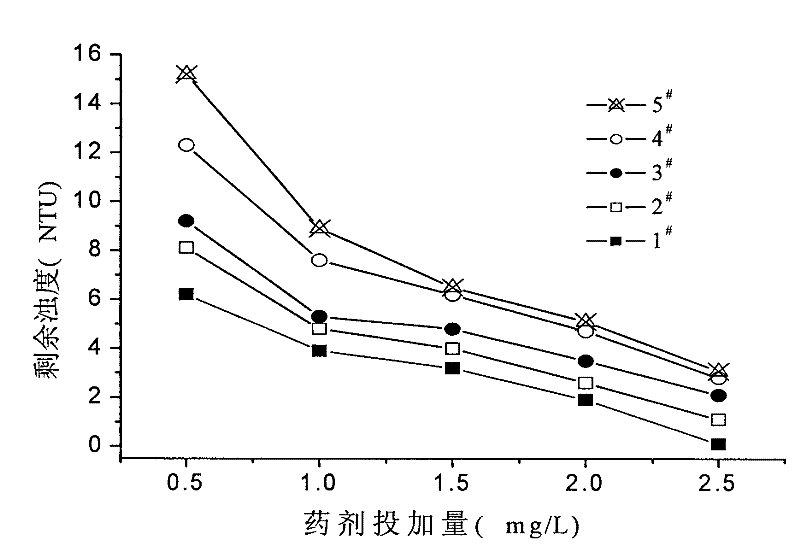

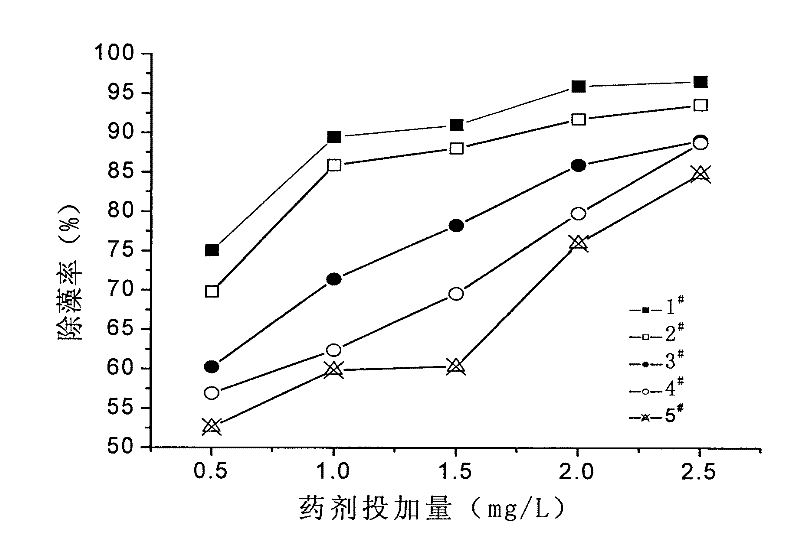

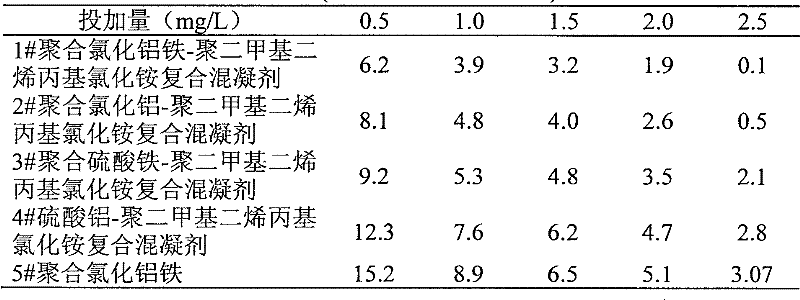

Image

Examples

Embodiment 1

[0034] (1) Heat the polyaluminum chloride solution to a temperature of 60°C under stirring conditions, add the polyferric chloride solution, continue heating and stirring for 1.5 hours, so that a copolymerization reaction occurs between the polyaluminum chloride and the polyferric chloride , get Al 2 o 3 The mass percentage content is 6%, with Fe 2 o 3 The polyaluminum ferric chloride solution that mass percent composition is 5% and salinity is 35%;

[0035] (2) Stir the polyaluminum ferric chloride solution obtained in step (1) at room temperature, add polydimethyldiallyl ammonium chloride that is 30% by mass in terms of solid content and has an intrinsic viscosity value of 3.7dL / g colloid, to obtain the mixed solution of the two; 2 o 3 +Fe 2 o 3 "The mass ratio of the total meter to polydimethyldiallylammonium chloride is 25:1;

[0036] (3) Stir the mixed solution obtained in step (2) at room temperature until the polydimethyldiallylammonium chloride colloid and the ...

Embodiment 2

[0038] (1) Heat the polyaluminum chloride solution to a temperature of 90°C under stirring, add the polyferric chloride solution, and continue heating and stirring for 0.5 hours to cause a copolymerization reaction between the polyaluminum chloride and the polyferric chloride , get Al 2 o 3 The mass percentage content is 10%, with Fe 2 o 3 The polyaluminum ferric chloride solution whose mass percent content is 1% and basicity is 90%;

[0039] (2) Stir the polyaluminium ferric chloride solution obtained in step (1) at room temperature, add polydimethyldiallyl ammonium chloride that is 50% by mass in terms of solid content and has an intrinsic viscosity value of 2.5dL / g colloid to obtain a mixed solution; the content of polyaluminum ferric chloride in the mixed solution is calculated as aluminum oxide and the mass ratio of polydimethyldiallylammonium chloride is 15:1;

[0040] (3) Stir the mixed solution obtained in step (2) at room temperature until the polydimethyldiallyl ...

Embodiment 3

[0042] (1) Heat the polyaluminum chloride solution to a temperature of 40°C under stirring, add the polyferric chloride solution, and continue heating and stirring for 2 hours to cause a copolymerization reaction between the polyaluminum chloride and the polyferric chloride , get Al 2 o 3 The mass percentage content is 8%, with Fe 2 o 3 The polyaluminum ferric chloride solution whose mass percent content is 3% and basicity is 70%;

[0043] (2) Stir the polyaluminum ferric chloride solution obtained in step (1) at room temperature, add polydimethyldiallyl ammonium chloride that is 60% by mass in terms of solid content and has an intrinsic viscosity value of 3.0dL / g Colloid, obtains mixed solution; The content of polyaluminum ferric chloride is expressed as Al in the described mixed solution 2 o 3 +Fe 2 o 3 The mass ratio of total amount meter and polydimethyldiallylammonium chloride is 10: 1;

[0044] (3) Stir the mixed solution obtained in step (2) at room temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com