Composite flocculant for piggery wastewater and biological fermentation treatment method and equipment

A composite flocculant and pig farm wastewater technology, which is applied in animal husbandry wastewater treatment, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc., can solve the problems of limited use, secondary pollution, and high treatment cost, and achieve The effect of reducing usage, saving energy consumption and improving fermentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

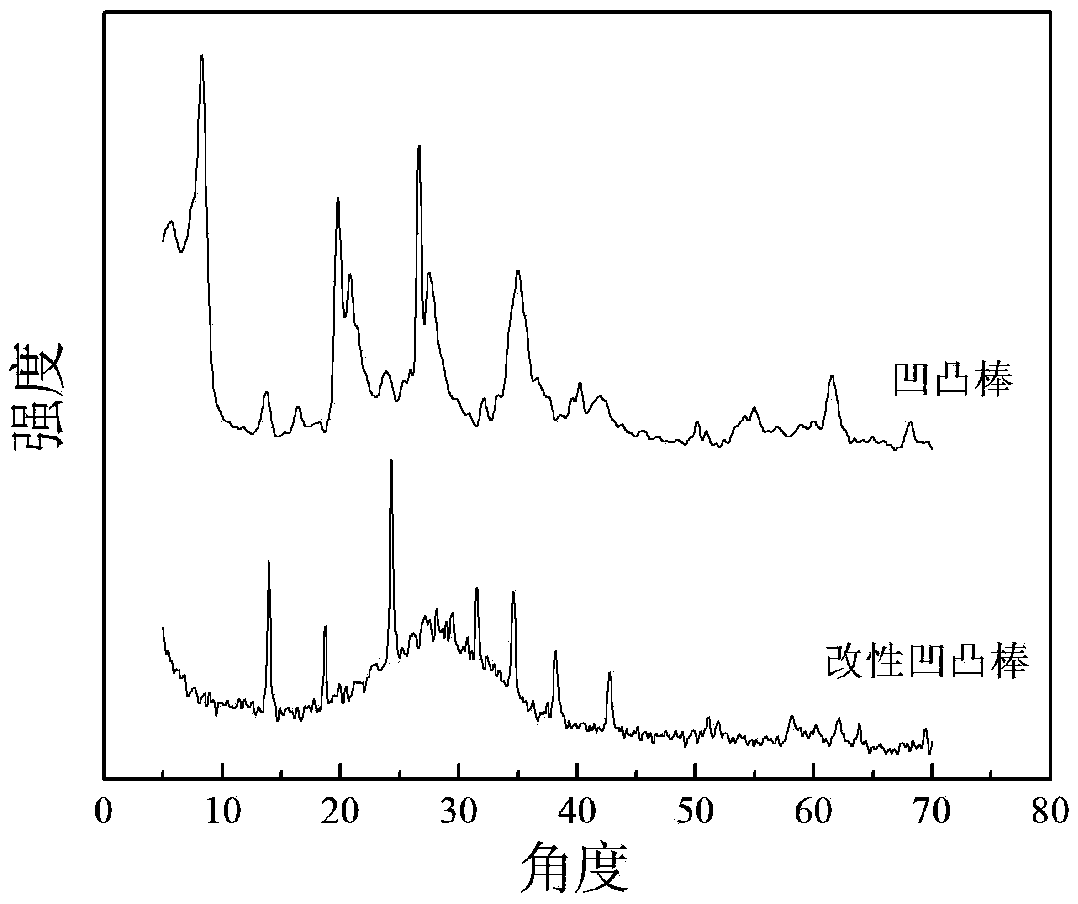

[0038] The composite flocculant of the present invention is formed by mixing equal quality modified attapulgite clay and sodium dichloroisocyanurate. The modification method of attapulgite clay is: mix attapulgite clay, chitin and polymeric sulfuric acid Mix the aluminum evenly according to the mass ratio of 4:1:1, add acetic acid with a concentration of 5% (m / v) to the above mixture and stir it into a paste, heat it in a water bath at 65°C for 2 hours, and then wash it with deionized water until The pH of the eluate is 7.2, then dried at 105 °C, and finally placed in a muffle furnace for roasting. The initial temperature of the roasting is 300 °C, and the roasting time is 2 hours. After cooling, the modified attapulgite clay is obtained. The crystal structures of unmodified attapulgite clay and modified attapulgite clay were determined by X-ray diffractometer, and the results were as follows: figure 1 shown. Depend on figure 1 It can be seen that when the diffraction angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com