Biological treatment method for waste mud in petroleum and natural gas exploration drilling work

A technology of oil and gas and waste mud, which is applied in the direction of biological sludge treatment, etc., can solve the problems of seepage liquid entering groundwater and water source pollution, and achieve the effect of anti-storm direct erosion, good effect and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The invention discloses a method for biological treatment of waste mud in oil and gas exploration and drilling operations. The steps include:

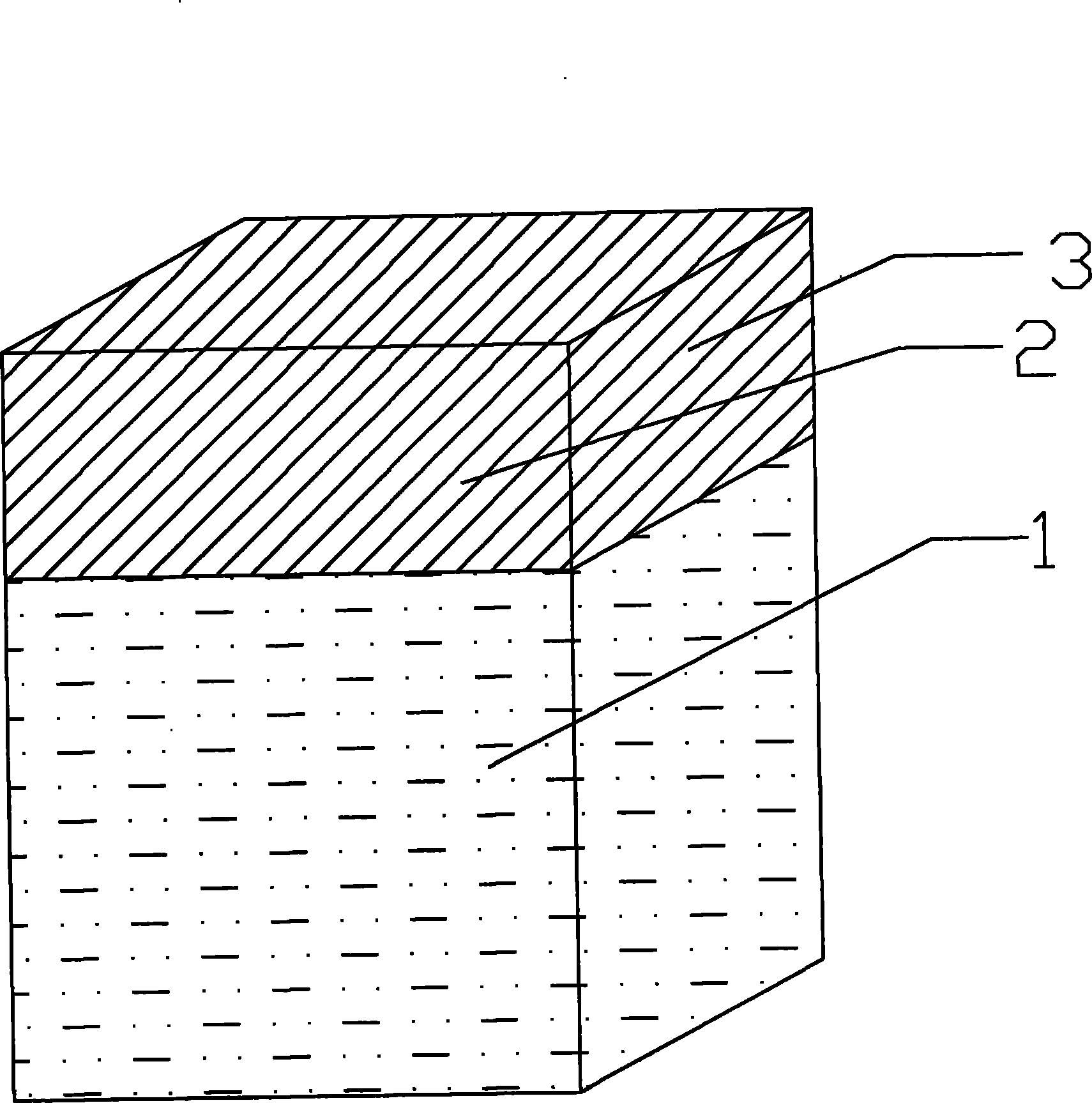

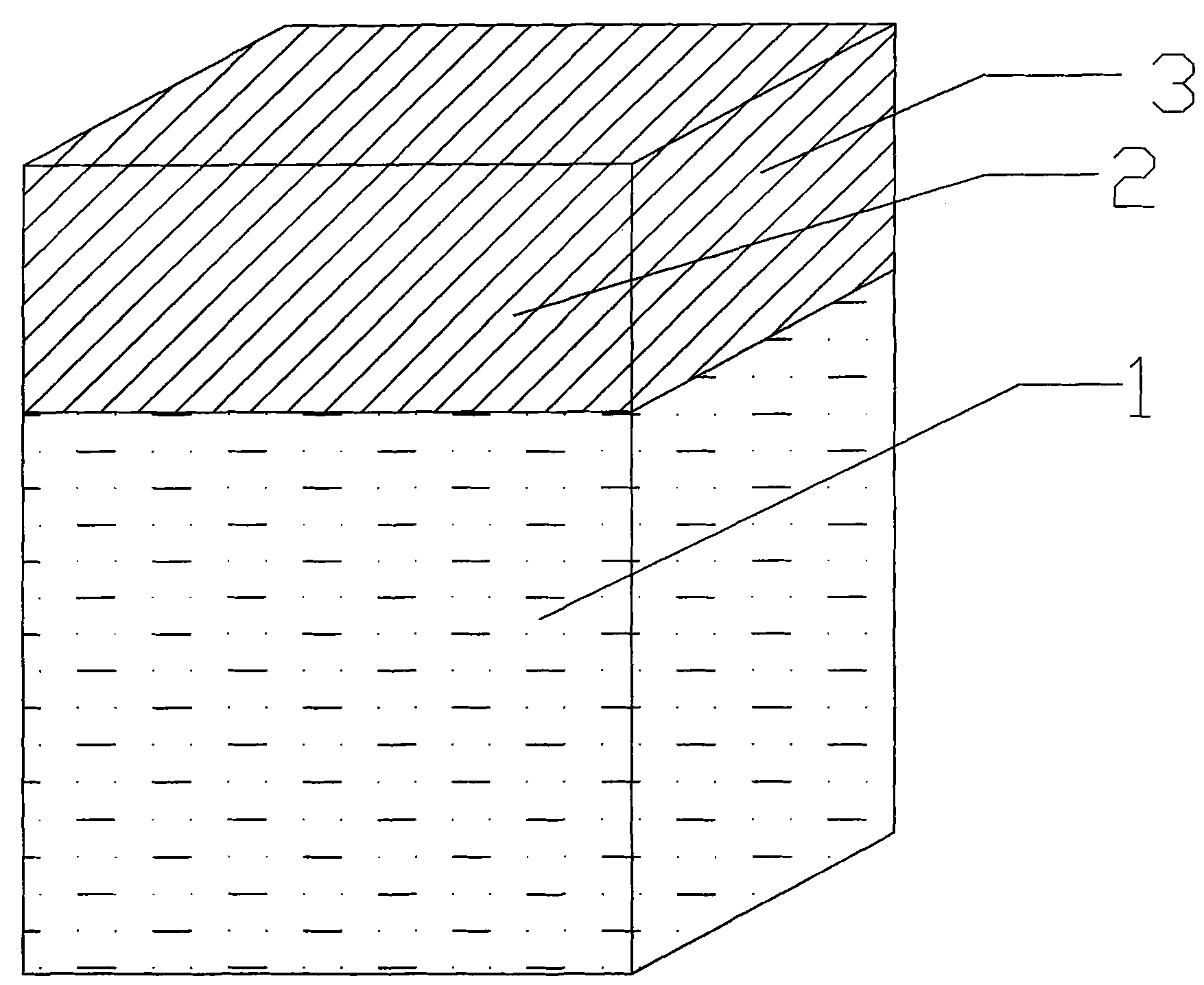

[0041] a. Microbial treatment layer 1, inoculate special microbial strains into the waste mud at a weight ratio of 3-5:100, and mix evenly; according to the density and water content of the waste mud 10%-15%, the particle size is <0.5cm The natural soil is fully stirred evenly in the following manner to form microbial treatment layer 1:

[0042] Add the natural soil by 2.5-3 times the weight to the waste mud with a density of 1-1.5kg / L;

[0043] Density is 1.5-2.5kg / L waste mud by adding described natural soil by 2-2.5 times weight;

[0044] Controlling the water content of the microbial treatment layer 1 is maintained between 25% and 30%;

[0045] The special-purpose microbial strains are high-pH resistant Halomonas bacteria, including 4 strains of Halomonasventosae bacteria, 1 strain of Halomonas campisalis bacteria, and 1 s...

Embodiment 2

[0049] As a preferred embodiment of the present invention, on the basis of Example 1, in step c, the leguminous and non-legume symbiotic nitrogen-fixing tree species are Leucaena or Alder. In the c step, the herb is miscanthus or clover. In the described a step, the added natural soil is after airing. In the step b, the soil in the plowing layer is natural soil with a water content of 10%-15% and a particle size of <0.5cm after drying. The percentages of the water content are weight ratios. The COD mentioned in the present invention refers to the COD index in the waste sludge treatment in the field of drilling, that is, the chemical oxygen demand and the oil index.

Embodiment approach

[0051] As another preferred embodiment of the present invention, the steps include:

[0052] a. Microbial treatment layer 1, inoculate the special microbial strains into the waste mud at a weight ratio of 5:100, mix evenly; press the natural soil with a particle size of 0.3 cm according to the density of the waste mud and water content of 12%. The above method is fully stirred evenly to form a microbial treatment layer 1:

[0053] Add the natural soil by 2.8 times the weight in the waste mud with a density of 1.2kg / L;

[0054] Controlling the water content of the microbial treatment layer 1 remains at 28%;

[0055] The special-purpose microbial strains are high-pH resistant Halomonas bacteria, including 4 strains of Halomonasventosae bacteria, 1 strain of Halomonas campisalis bacteria, and 1 strain of Bacillus megaterium in the genus Bacillus;

[0056] B, soil treatment: the microbial treatment layer 1 formed in step a is buried in the tunnel formed in the excavation of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com