High-concentration nonionic surfactant wastewater treatment device and method

A non-ionic surface and wastewater treatment technology, applied in water/sewage treatment, chemical instruments and methods, special compound water treatment, etc., can solve the problems of not cheap and easy to obtain, difficult to deal with, secondary pollution, etc., and achieve practical promotion value , good operation effect, large-scale processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

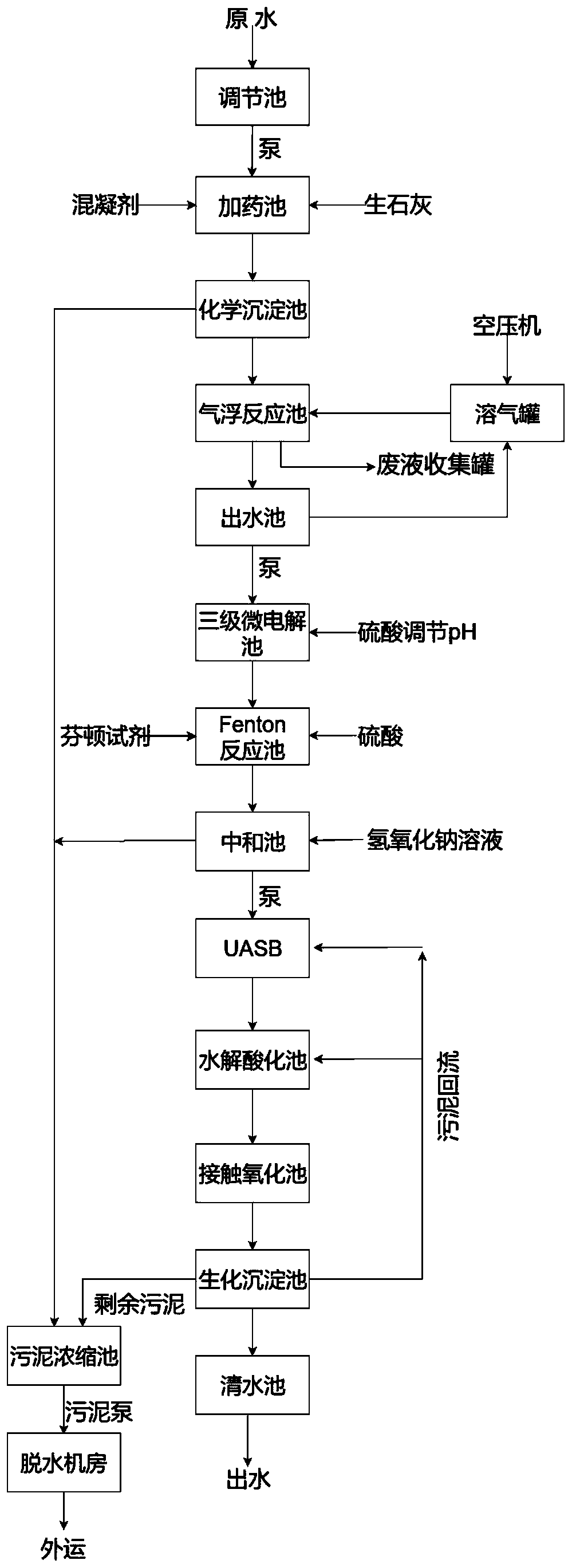

[0041] Such as figure 1 Shown is a flow chart of the present invention for treating high-concentration nonionic surfactant wastewater system and process.

[0042] The measured value of COD of non-ionic surfactant wastewater in a certain factory is 250000mg / L, the concentration of alkylphenol polyoxyethylene ether is 1%, and the pH is 5.6. It is treated according to the following steps:

[0043] First, the wastewater containing alkylphenol polyoxyethylene ether entering the regulating tank is stirred by the water pump circulation to adjust the water quality, and the COD concentration of the regulating tank is controlled to be 230000mg / L, and the effluent flow rate is 15m 3 / d, the concentration of nonionic surfactant is 0.9%. In the dosing pool, first add 45kg / kt of water PFS, then add CaO to control the pH to 9.0, and finally add PAM12kg / kt of water. In the chemical sedimentation tank, carry out coagulation and sedimentation for 10 hours. The water body after coagulation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com