Sludge activating ball and manufacture method thereof

A sludge and weight percentage technology, applied in biological sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of large sewage treatment facilities such as environmental emission reduction benefit discounts, and achieve control of secondary Pollution, quick effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

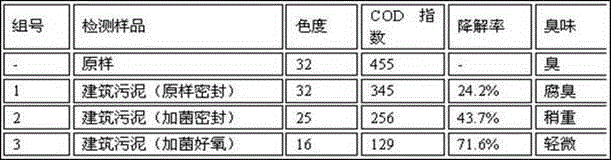

Examples

Embodiment 1

[0048] Sludge activation balls are prepared from the following raw materials:

[0049] Burnet 2% by weight

[0050] Patrinia 2% by weight

[0051] 2% earth dragon by weight

[0052] The weight percentage is 2% blood vine

[0053] Percentage by weight is 2% cnidium

[0054] 2% old ginger by weight

[0055] 2% sea salt by weight

[0056] 10% by weight brown sugar

[0057] 12% by weight wheat bran

[0058] 14% volcanic soil by weight

[0059] 25% by weight distilled wood vinegar

[0060] Percentage by weight is 25% environmentally friendly Yang element;

[0061] Environmentally friendly Yangsu is one or more active enzymes extracted from bananas, pumpkins, papayas, pineapples, lemons, longans, and apples by pickling, fermentation, and alcoholization.

[0062] The manufacturing method of the sludge activation ball comprises the following steps:

[0063] ①. Remove and crush the impurities in the volcanic soil;

Embodiment 2

[0070] Sludge activation balls are prepared from the following raw materials:

[0071] Burnet 2.14% by weight

[0072] Percentage by weight is 2.14% Patrinia

[0073] Dilong with a weight percentage of 2.14%

[0074] Percentage by weight is 2.14% of Sagittarius

[0075] Percentage by weight is 2.14% cnidium

[0076] The old ginger of 2.14% by weight

[0077] 2.14% sea salt by weight

[0078] 10% by weight brown sugar

[0079] 10% by weight wheat bran

[0080] 15% by weight volcanic soil

[0081] 25% by weight distilled wood vinegar

[0082] Percentage by weight is 25% environmentally friendly Yang element;

[0083] In the above scheme, the environmental protection yang element is one or more active enzymes extracted from bananas, pumpkins, papayas, pineapples, lemons, longan, and apples by pickling, fermentation, and filtration and alcoholization.

[0084] The manufacturing method of the sludge activation ball comprises the following steps:

[0085] ①. Remove and cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com