Composite medium-effect disinfectant and preparation process thereof

A disinfectant and disinfectant technology, applied in the direction of disinfectant, active ingredients of heterocyclic compounds, medical preparations of non-active ingredients, etc., to achieve reliable safety, control of secondary pollution, and good disinfection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A preparation method of a disinfectant with compound intermediate-effect disinfection function, comprising the following steps:

[0050] (1) Put deionized water in a stirring tank, add surfactant, and stir at a speed of 120r / min for 10-15min until uniform;

[0051] (2) Then add compound disinfectant and stir for about 8 minutes at a speed of 60r / min;

[0052] (3) Add a stabilizer, then stir for about 12 minutes at a speed of 120r / min;

[0053] (4) Add ZnO and TiO 2 The sol was mixed again, and stirred at a speed of 60r / min for 18 minutes to obtain a disinfectant with a medium-efficiency disinfection function.

[0054] The preparation method of disinfectant solution among the embodiment 2~6 is the same as embodiment, only has difference with embodiment 1 on the selection of raw material. Concrete raw material ratio is as follows:

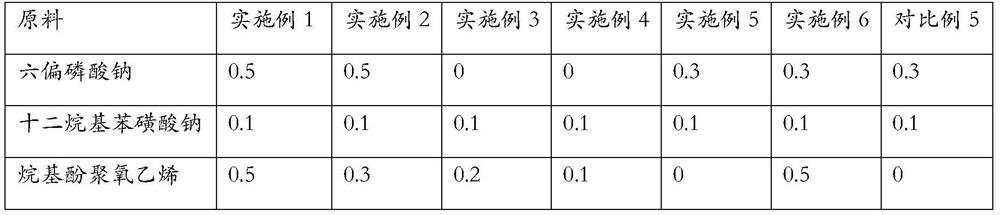

[0055] Proportioning (g) of each raw material among table 1 embodiment 1~6

[0056]

[0057]

Embodiment 7

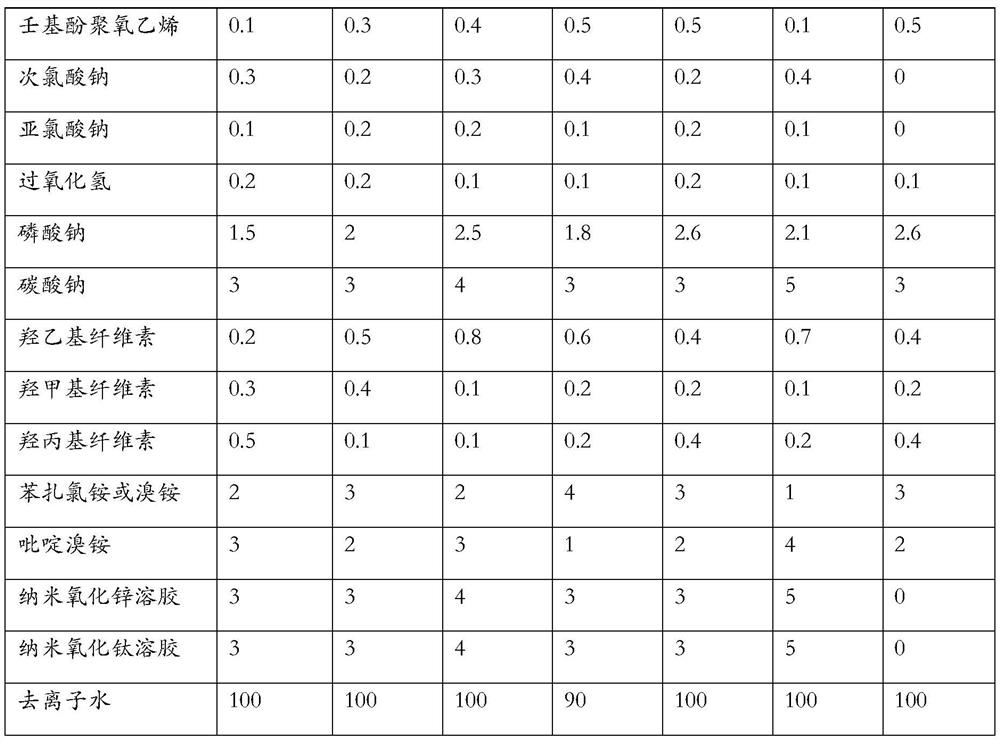

[0078] According to the method in the "Disinfection Technical Specification" (2002 edition) 2.1.1.7.5 carrier immersion sterilization test, the prepared disinfection powder is carried out carrier immersion quantitative sterilization test, and the killing rate (%) results are as follows:

[0079] The disinfection solution in each embodiment of table 2 is for the killing rate (%) of Escherichia coli and Staphylococcus aureus

[0080]

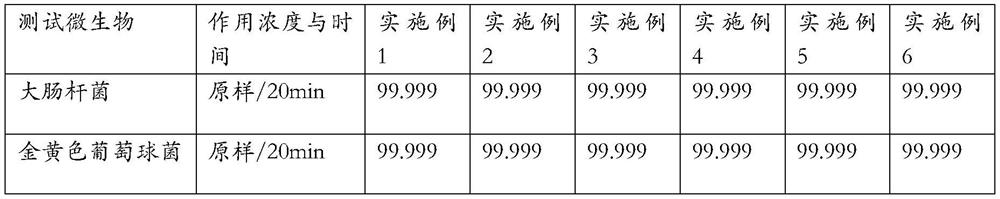

[0081] Table 3 The killing rate (%) of the disinfectant solution in each comparative example for Escherichia coli and Staphylococcus aureus

[0082] test microorganism Comparative example 1 Comparative example 2 Comparative example 3 Comparative example 4 Comparative example 5 Escherichia coli 96.541 92.223 75.454 45.314 56.153 Staphylococcus aureus 92.245 93.453 73.121 48.322 57.746

[0083] It can be seen from Table 2 that the killing rate of the disinfectant in the embodiment can reach 99.999% for E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com