A method for dechlorinating ash by using garbage

A kind of ash and garbage technology, which is applied in the direction of recycling technology, solid waste removal, waste treatment, etc., can solve the problems of inability to realize ash treatment and consumption, limit the amount of ash utilization, etc., and achieve efficient resource utilization, Reduced mass consumption and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Sorting the ash to make the particle size less than 2cm, sorting and magnetic separation to remove metal and plastic, select the garbage that has been buried for 5-6 years, and remove the plastic, metal, large stones, wood, etc., so that Its particle size is less than 10cm;

[0040] (2) The above-mentioned ash and old garbage are uniformly mixed in the desalination tank at a mass ratio of 9:1;

[0041] (3) Install a rinsing cloth pipe above the desalination tank, and regularly rinsing the desalination tank every day. According to the calculation of Shanghai’s annual average rainfall of 1178.2mm in the past five years, the rinsing water volume is 6.5mm / day, and the rinsing cycle is 30 weeks .

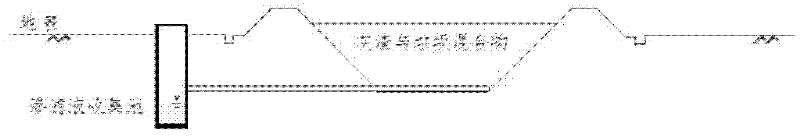

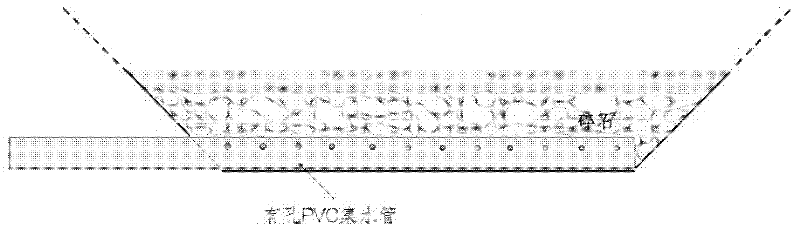

[0042] A leachate collection pipe is installed at the bottom, and ash residue and leachate are regularly sampled and analyzed. The specific structure and size of the desalination tank and water distribution system are as follows: Figure 2-5 shown. Use AQF-ion chromatograp...

Embodiment 2

[0046] (1) Sorting the ash and slag to make the particle size less than 2cm, remove the metal and plastic, select the garbage that has been landfilled for 5-6 years, and remove the plastic, metal, large stones, wood blocks, etc., so that the particle size is less than 10cm ;

[0047] (2) The above-mentioned ash and old garbage are uniformly mixed in the desalination tank at a mass ratio of 19:1;

[0048] (3) Install a rinsing cloth pipe above the desalination tank, and regularly rinsing the desalination tank every day. According to the calculation of the annual average rainfall of 1178.2mm in Shanghai in the past five years, the rinsing water volume is 6.5mm / day, and the rinsing cycle is 50 weeks .

[0049] A leachate collection pipe is installed at the bottom, and ash residue and leachate are regularly sampled and analyzed.

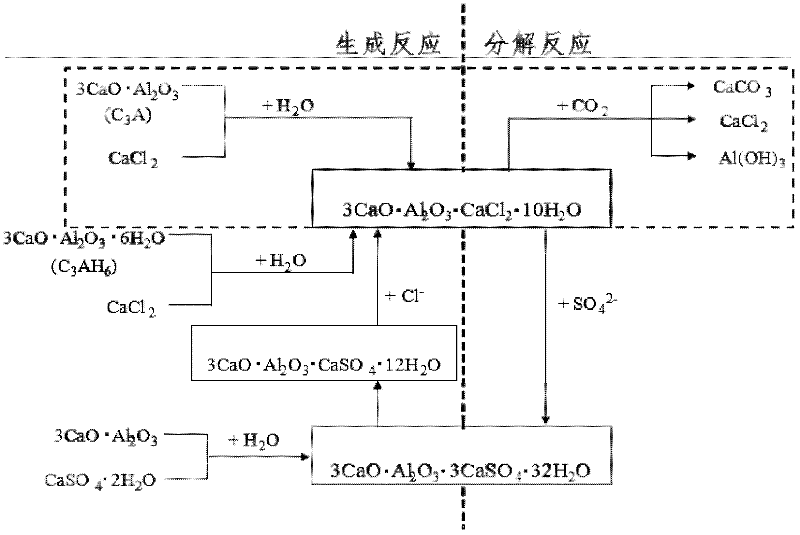

[0050] figure 1 Shown is the reaction mechanism of using garbage to dechlorinate ash in the present invention.

[0051] The specific structure of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com