Method for purifying microalgae biomass harvested by coagulation and recycling coagulant

A coagulant and biomass technology, applied in the field of microalgae cultivation, can solve problems such as operational complexity, gas leakage, and storage difficulties, and achieve the effects of reducing negative impacts, reducing process costs, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

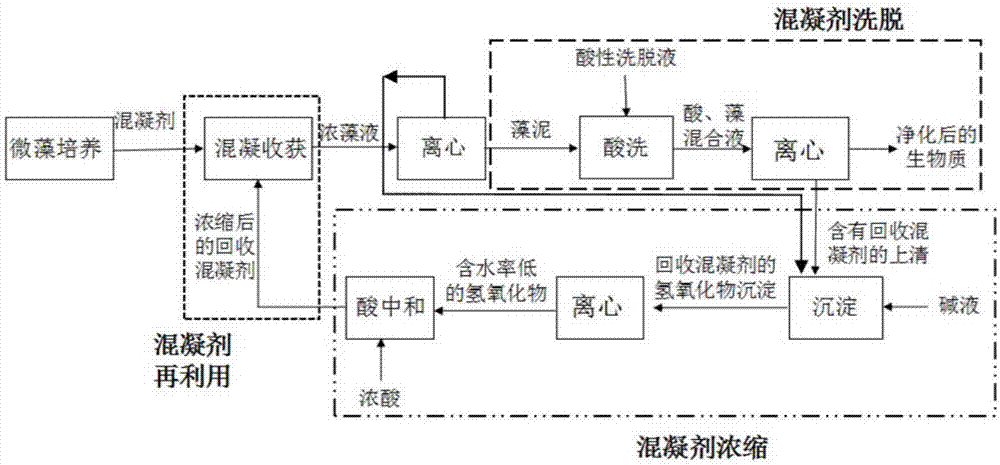

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

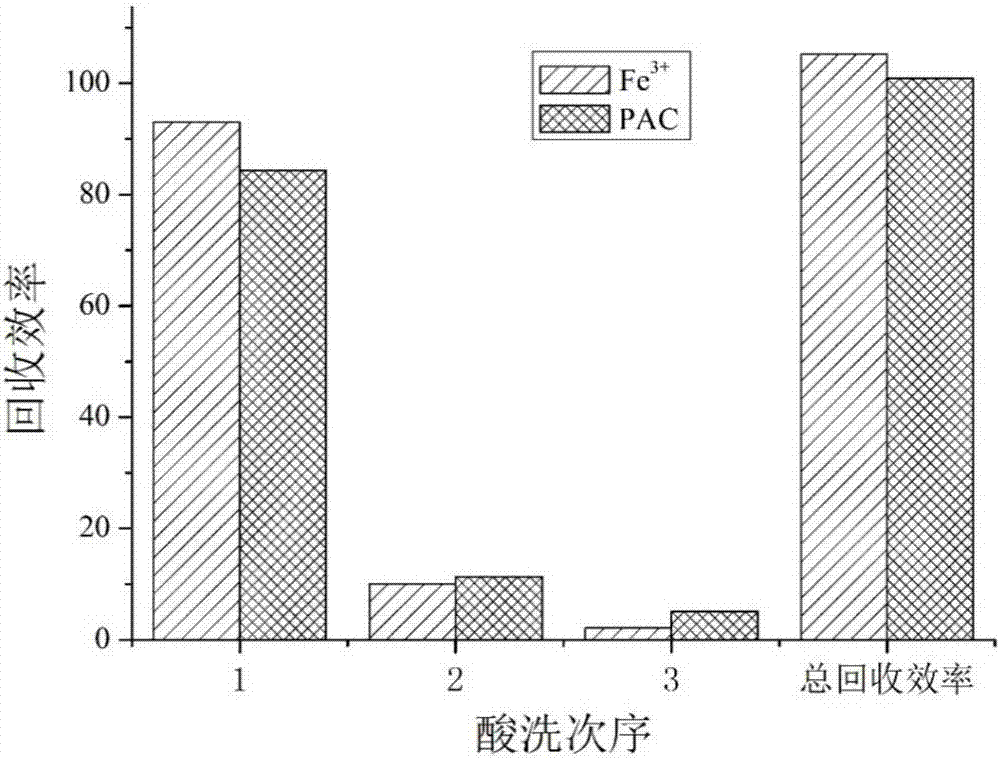

[0052] see figure 2 , figure 2 It shows the comparison of the recovery efficiency of iron salt and PAC recovered from Scenedesmus after harvesting Scenedesmus with iron salt and PAC as coagulants respectively.

[0053] Experimental conditions: iron salts (FeCl 3 ) and PAC (purchased from Shanghai Sinopharm) to coagulate and harvest Scenedesmus, use acidic eluent to elute and recover the coagulant in Scenedesmus and purify the biomass. The samples of the same volume were taken from the same microalgae culture tank, the dosage of PAC was 9.8 mg / g (9.8 mg of PAC was added to each gram of algal liquid), and the pH was adjusted to 6.2±0.2; FeCl 3 The dosage is 40mg / g (add 40mg FeCl to each gram of algae liquid 3 ). When eluting with an acidic eluent, use HCl=0.1mol / L, and liquid-solid ratio=200ml / g. After elution, the collected supernatant was adjusted to pH 5-8 by using NaOH=5mol / L to obtain hydroxide precipitation. Settling and centrifuging to obtain the hydroxide of the ...

Embodiment 2

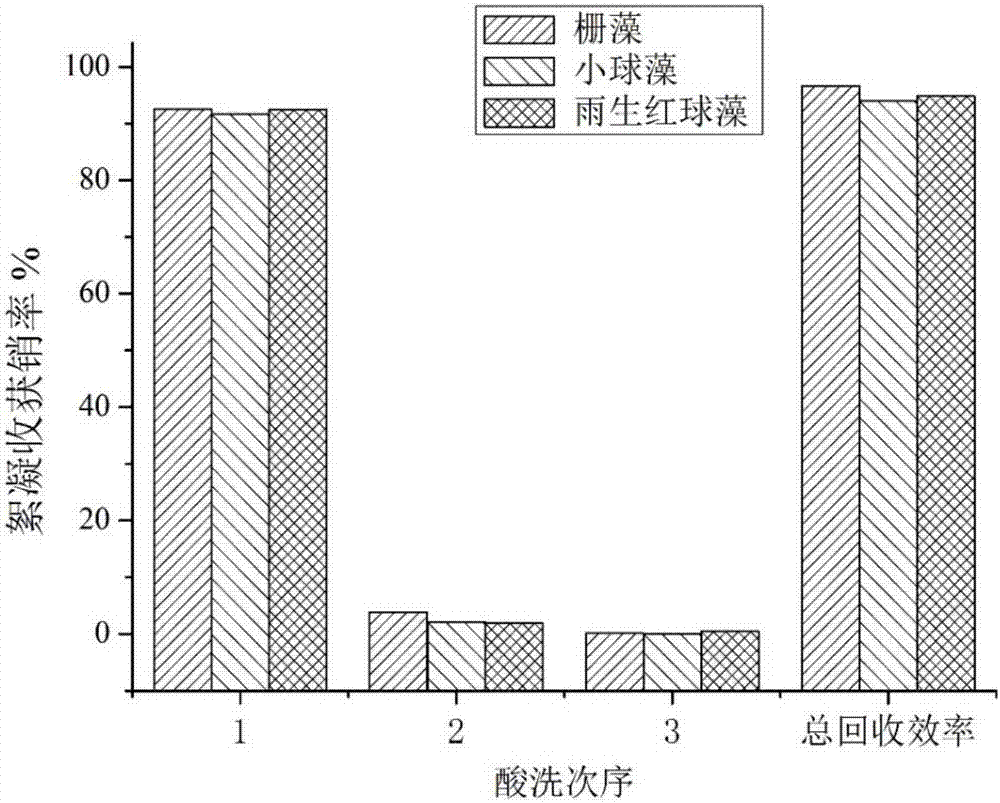

[0056] see image 3 , image 3 A graph showing the comparison of recovery efficiencies of aluminum salt coagulants from coagulation-harvested different microalgal biomass (Scenesus, Chlorella, and Haematococcus pluvialis).

[0057] Experimental conditions: For Scenedesmus acuminatus, Chlorellasorokiniana, and Haematococcus pluvialis, the algal liquids were harvested by coagulation; 3+ After (aluminum sulfate), adjust pH=6.2±0.2; during acid washing, HCl=0.1mol / L, liquid-solid ratio=200ml / g.

[0058] After elution, the collected supernatant was adjusted to pH 5-8 by using NaOH=5mol / L to obtain hydroxide precipitation. Settling and centrifuging to obtain the hydroxide of the recovered coagulant with very low water content, adding sulfuric acid to it, and completely neutralizing and dissolving the hydroxide, that is, the concentrated recovered coagulant aluminum sulfate is obtained.

[0059] The experimental results are as image 3 shown. Under the above-mentioned experiment...

Embodiment 3

[0062] see Figure 4-5 . in Figure 4 A graph showing the comparison of the harvesting efficiency of the freshly prepared aluminum salt solution and the aluminum salt solution recovered by the method of the present invention as a coagulant for harvesting microalgae.

[0063] Figure 5 The photo shown is a photo of the microalgae sedimentation after the newly prepared aluminum salt solution and the recovered aluminum salt solution are added as a coagulant to a beaker containing algae liquid, and the same time (15 min) has elapsed.

[0064] Experimental conditions: Take Scenedesmus acuminatus and aluminum sulfate as examples, use acidic eluent to recover aluminum salt coagulant, and study the recovery of coagulant according to the method of the present invention when it is used for harvesting microalgae, its harvest Whether the efficiency will be consistent with the harvest efficiency of the analytically pure coagulant purchased by the original factory (purchased from Shangha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com