A kind of laminated thick steel paper and preparation method thereof

A technology of steel paper and thin steel paper, applied in the field of steel paper, can solve the problems of poor dispersion of flame retardants, unsatisfactory flame retardant insulation of paper, etc., and achieve the effects of improving strength, reducing flocculation and high flame retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the preparation of laminated thick steel paper comprises the following steps:

[0030] (1) Evenly disperse 10g of montmorillonite in 100g of distilled water, add 50g of 3.8g / L polyepichlorohydrin dimethylamine aqueous solution, stir for 7h, perform suction filtration, put the filter cake at 106°C for 1.5h, It is then ground to obtain a modified montmorillonite;

[0031] (2) 20g cotton fiber, 50g phenylenediamide phthalamide fiber are mixed with 1kg of water for beating, then, add 0.2g modified montmorillonite and 0.25g polyethylene oxide, mix uniformly to obtain mixed slurry;

[0032] (3) Put the mixed slurry into the paper machine, carry out papermaking, press and dehydrate, and obtain the steel paper base paper after drying;

[0033] (4) Put the steel paper base paper into the ammonium phosphate flame-retardant impregnation solution for impregnation and adsorption for 15 minutes;

[0034] (5) Put the impregnated base paper into 20mg / L graphene oxide aq...

Embodiment 2

[0038] Embodiment 2: the preparation of laminated thick steel paper comprises the following steps:

[0039](1) Evenly disperse 10g of montmorillonite in 100g of distilled water, add 50g of 4.3g / L polyepichlorohydrin dimethylamine aqueous solution, stir for 8h, perform suction filtration, put the filter cake at 109°C for 2h, then Grinding it to obtain modified montmorillonite;

[0040] (2) 22g cotton fibers, 55g phenylenediamide phthalamide fibers are mixed with 1.2kg of water for beating, then, add 0.3g modified montmorillonite and 0.45g polyethylene oxide, mix uniformly to obtain mixed slurry;

[0041] (3) Put the mixed slurry into the paper machine, carry out papermaking, press and dehydrate, and obtain the steel paper base paper after drying;

[0042] (4) Put the steel paper base paper into the ammonium phosphate flame-retardant impregnation solution for impregnation and adsorption for 20 minutes;

[0043] (5) Soak the steel base paper in 25mg / L graphene oxide aqueous sol...

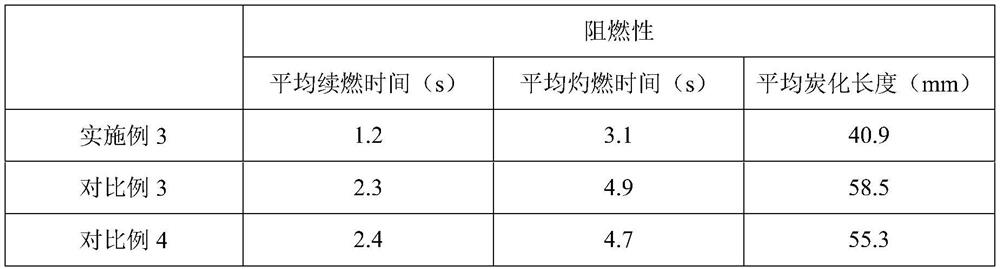

Embodiment 3

[0047] Embodiment 3: the preparation of laminated thick steel paper comprises the following steps:

[0048] (1) Evenly disperse 10g of montmorillonite in 100g of distilled water, add 110g of 2.5g / L polyepichlorohydrin dimethylamine aqueous solution, stir for 8h, perform suction filtration, put the filter cake at 113°C for 3h, then Grinding it to obtain modified montmorillonite;

[0049] (2) 28g cotton fibers, 65g phenylenediamide phthalamide fibers are mixed with 1.5kg of water for beating, then, add 0.3g modified montmorillonite and 0.48g polyethylene oxide, mix uniformly to obtain mixed slurry;

[0050] (3) Put the mixed slurry into the paper machine, carry out papermaking, press and dehydrate, and obtain the steel paper base paper after drying;

[0051] (4) Put the steel paper base paper into the ammonium phosphate flame-retardant impregnation solution for impregnation and adsorption for 25 minutes;

[0052] (5) Soak base paper in 35mg / L graphene oxide aqueous solution fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com