Salt-free dyeing method of cationic modified cotton fabric

A salt-free dyeing technology for cotton fabrics, applied in the field of dyeing, can solve the problems of low dyeing rate and high pollution, and achieve the effect of avoiding environmental pollution and saving reactive dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, the cotton fabric is dyed by using the salt-free dyeing method in this application.

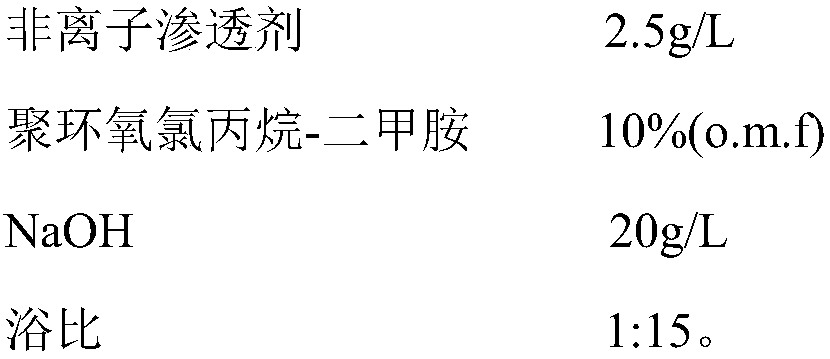

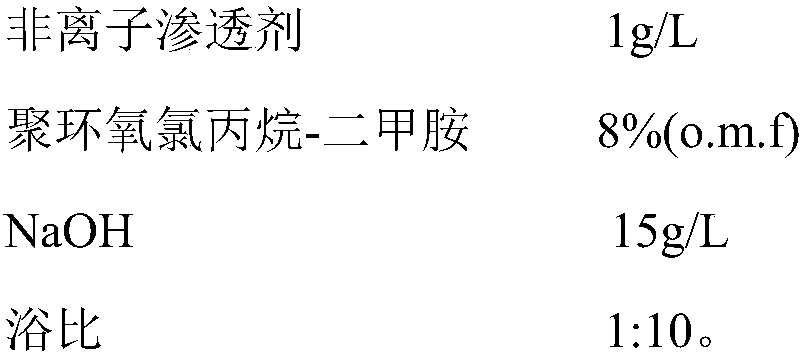

[0040] The process and formula of cationic modification treatment are as follows:

[0041]

[0042] Add penetrating agent and modifier in the water bath first, then put the cotton fabric to be treated for immersion for 10 minutes, then add NaOH, continue to immerse for 10 minutes, after the second dipping and second rolling, the residual rate is 85%. Wash with water for 15 minutes, then wash in cold water until neutral, dry and wait for dyeing.

[0043] Salt-free dyeing: dye dosage 4% (omf), liquor ratio 1:15, dyeing at 60°C for 30min, adding Na 2 CO 3 (15g / L) keep warm at 60°C for 30min, wash with water and soap. The dye used for dyeing is specifically Drimarene red.

Embodiment 2

[0045] The difference between this example and Example 1 is that the cotton fabric to be dyed is not subjected to cationic modification treatment but is directly dyed without salt, and the process of dyeing unmodified cotton without salt is the same as that of Example 1.

Embodiment 3

[0047] The difference between this example and Example 1 is that the cotton fabric to be dyed is directly carried out without cationic modification treatment, and is dyed with salt, and the salt dyeing process of the cotton fabric to be dyed is added at the initial stage. 60g / L Na 2 SO 4 , and then add dye for coloring.

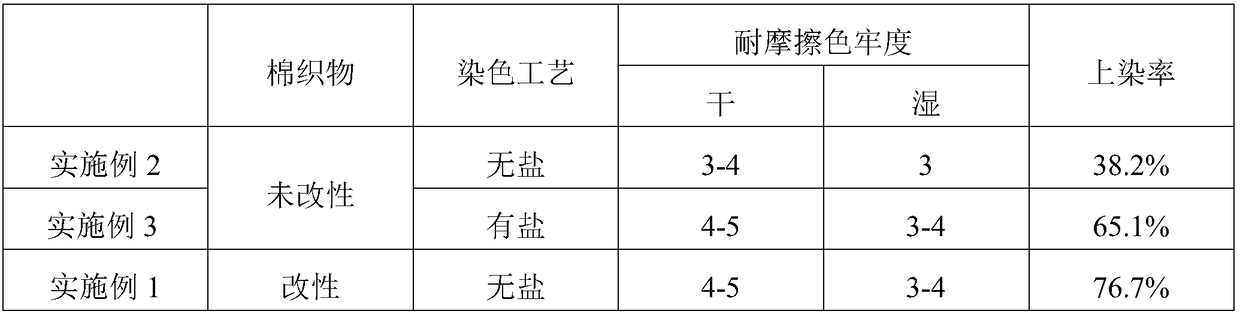

[0048] Effects are as shown in Table 1 in Examples 1-3.

[0049] Table 1

[0050]

[0051] It can be seen from the above table that the dyeing rate of salt-free dyeing of cotton fabrics modified by cations is much higher than that of conventional cotton fabrics dyed with salt, and the color fastness to rubbing is equivalent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com