Environment-friendly water-based paint and preparation method thereof

A water-based paint, environmental protection technology, applied in the direction of lignin paint, chitin polysaccharide paint, hyaluronic acid paint, etc., can solve the problems of shrinkage and deformation of the paint, cracking of the paint, etc., to reduce cracking, reduce drying shrinkage, and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Environmentally friendly water-based paint raw materials include the following components: water-based polyurethane 50kg, bentonite 15kg, chitosan quaternary ammonium salt 9kg, lignin fiber 13kg, polyepichlorohydrin dimethylamine 6kg, far-infrared ceramic powder 3kg, cetyl tris Methyl ammonium bromide 2kg, anti-cracking agent 10kg, dispersant 6kg, anti-aging agent 2 parts, water 52kg. Environmentally friendly water-based paint raw materials also include 3kg of film-forming aids and 1kg of wetting agents. The film-forming aids include but not limited to ethylene glycol, the wetting agents include but not limited to propylene glycol, and the anti-aging agent is titanium dioxide.

[0038] Wherein the dispersant is starch phosphate. The anti-cracking agent includes sodium alginate and hydroxypropyl methylcellulose, and the mass ratio of sodium alginate and hydroxypropyl methylcellulose is 3:1.

[0039] A preparation method for environment-friendly water-based paint, compri...

Embodiment 2-10

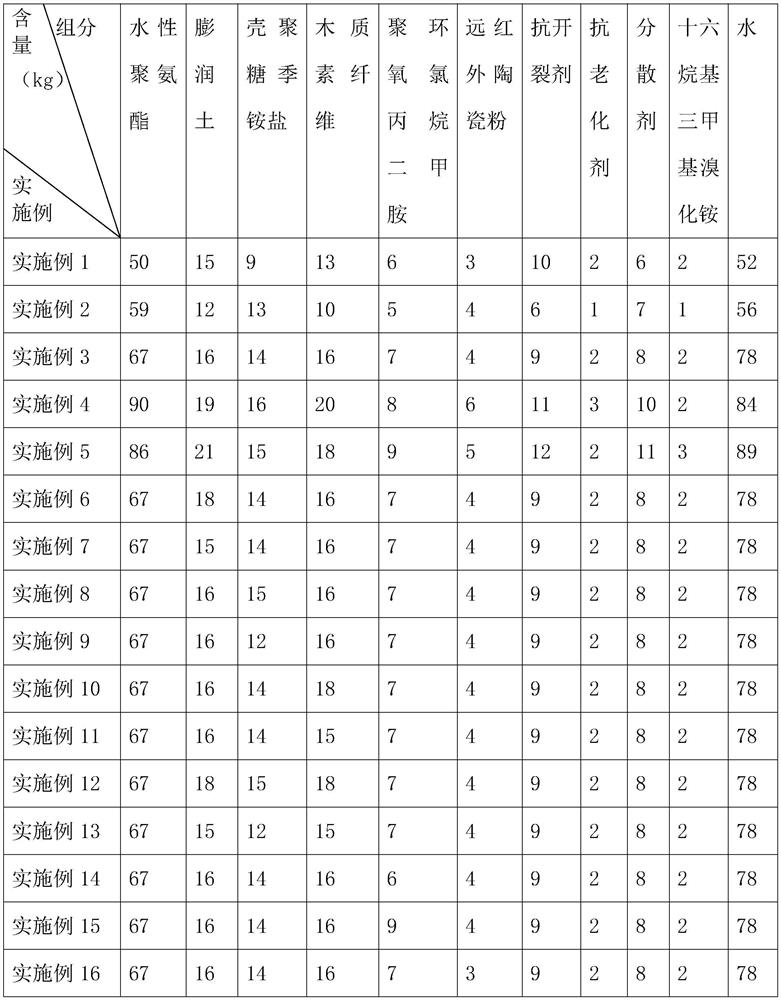

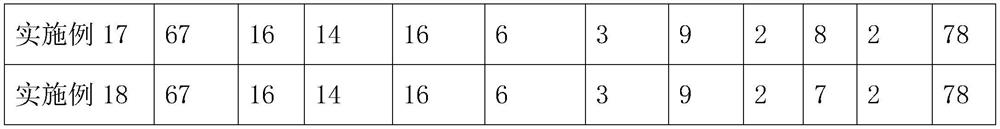

[0044] The difference between Example 2-10 and Example 1 is that the component content of Example 2-10 is different from that of Example 1, see Table 1 for details.

[0045] Table 1 embodiment 1-10 component content table

[0046]

[0047]

Embodiment 19

[0049] The difference between Example 19 and Example 3 is that the raw materials of the water-based environmental protection paint also include the following components: 7kg of hydroxyapatite and 20kg of erythritol.

[0050] The difference between the preparation method of the water-based paint of Example 19 and the preparation method of the water-based paint of Example 3 is: cetyltrimethylammonium bromide and hydroxyapatite are mixed for 10 minutes at a speed of 60 rpm , to obtain the second premix; dispersant, anti-cracking agent main agent and far-infrared ceramic powder are added in the first premix, and at 60 rpm, mix for 20 minutes, then add chitosan quaternary ammonium salt, The second premixture, erythritol and polyepichlorohydrin dimethylamine were mixed for 20 minutes at a speed of 60 rpm to obtain a water-based paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com