Viscose fiber fabric finishing agent and method for applying same

A viscose fiber and finishing agent technology, applied in the field of clothing fabrics, can solve the problems of high production cost, complicated spinning production, reduced mechanical properties of protein viscose fibers, etc., and achieve the effects of excellent antibacterial properties and good air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

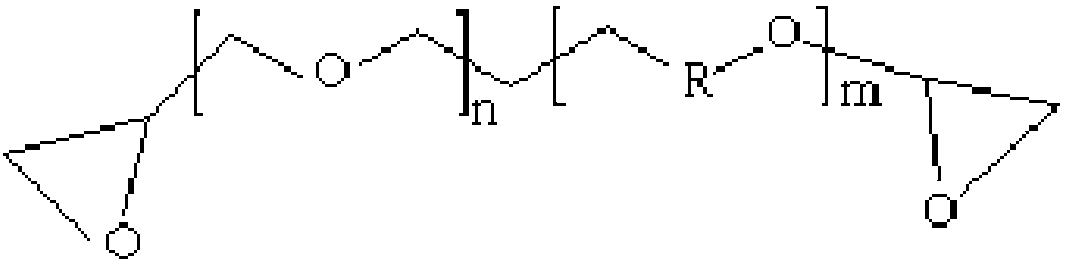

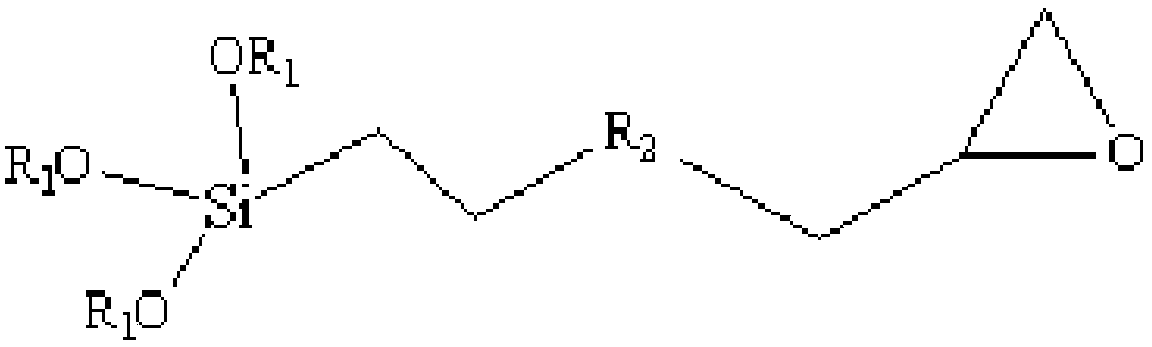

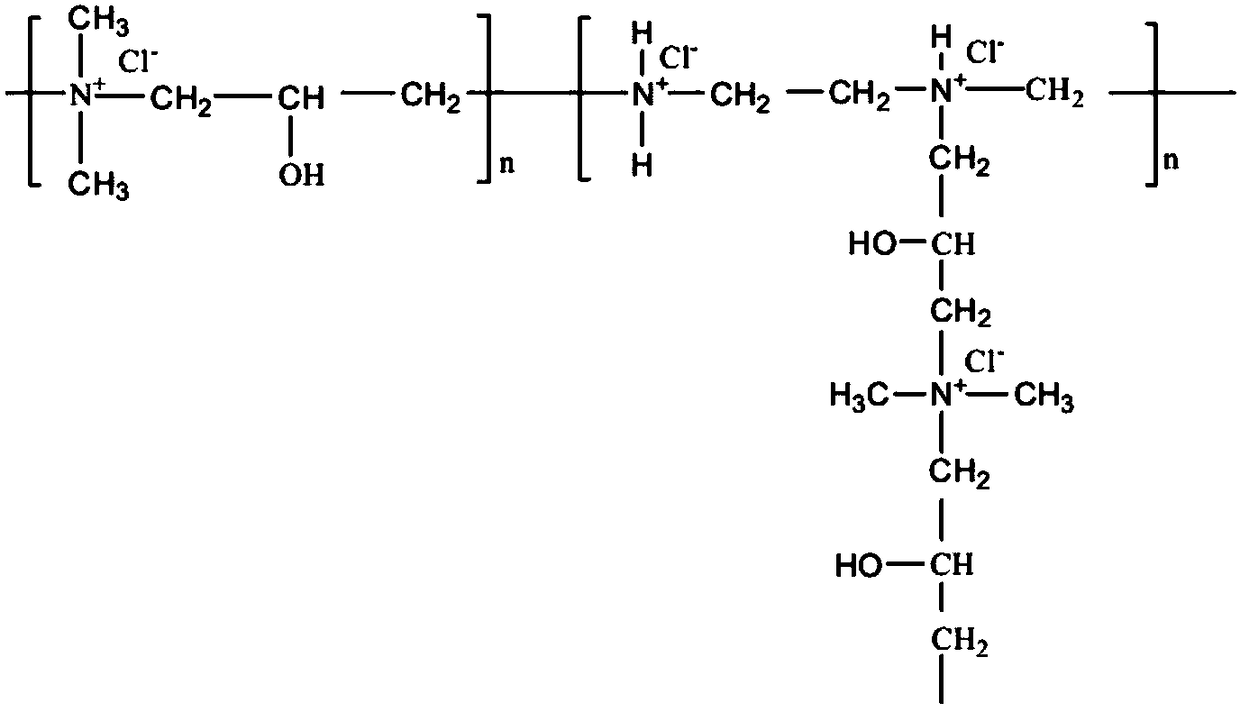

[0062] A finishing agent for viscose fiber fabrics, comprising, in parts by weight: 5 parts of silkworm chrysalis protein; 5 parts of epoxy crosslinking agent; 2 parts of polyepichlorohydrin dimethylamine; 1.0 parts of magnesium chloride; 5 parts of absolute ethanol; 2 parts of sodium citrate; 50 parts of deionized water.

[0063] Wherein, the epoxy crosslinking agent is a diepoxide or a silicone monoepoxide.

[0064] The using method of this viscose fabric finishing agent comprises the following steps:

[0065] Step 1, preparing silkworm chrysalis protein solution.

[0066] Step 2, successively weigh polyepichlorohydrin dimethylamine, epoxy crosslinking agent, absolute ethanol, magnesium chloride, sodium citrate and add them to the Erlenmeyer flask, then add deionized water, and place the Erlenmeyer flask at 30 In a shaker at ℃, shake until the epoxy crosslinking agent is completely dissolved to prepare a finishing solution.

[0067] Step 3, immerse the viscose fiber fabri...

Embodiment 2

[0072] A finishing agent for viscose fiber fabrics, comprising: 10 parts of silkworm chrysalis protein; 7 parts of epoxy crosslinking agent; 4 parts of polyepichlorohydrin dimethylamine; 1.2 parts of magnesium chloride; 7 parts of absolute ethanol; 3 parts of sodium citrate; 55 parts of deionized water.

[0073] Wherein, the epoxy crosslinking agent is a diepoxide or a silicone monoepoxide.

[0074] The using method of this viscose fabric finishing agent comprises the following steps:

[0075] Step 1, preparing silkworm chrysalis protein solution.

[0076] Step 2, successively weigh polyepichlorohydrin dimethylamine, epoxy crosslinking agent, absolute ethanol, magnesium chloride, sodium citrate and add them to the Erlenmeyer flask, then add deionized water, and place the Erlenmeyer flask at 30 In a shaker at ℃, shake until the epoxy crosslinking agent is completely dissolved to prepare a finishing solution.

[0077] Step 3, immerse the viscose fiber fabric in the above-ment...

Embodiment 3

[0082] A finishing agent for viscose fiber fabrics, comprising, in parts by weight: 12 parts of silkworm chrysalis protein; 9 parts of epoxy crosslinking agent; 6 parts of polyepichlorohydrin dimethylamine; 1.2 parts of magnesium chloride; 9 parts of absolute ethanol; 4 parts of sodium citrate; 55 parts of deionized water.

[0083] Wherein, the epoxy crosslinking agent is a diepoxide or a silicone monoepoxide.

[0084] The using method of this viscose fabric finishing agent comprises the following steps:

[0085] Step 1, preparing silkworm chrysalis protein solution.

[0086] Step 2, successively weigh polyepichlorohydrin dimethylamine, epoxy crosslinking agent, absolute ethanol, magnesium chloride, sodium citrate and add them to the Erlenmeyer flask, then add deionized water, and place the Erlenmeyer flask at 30 In a shaker at ℃, shake until the epoxy crosslinking agent is completely dissolved to prepare a finishing solution.

[0087] Step 3, immerse the viscose fiber fabr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com