Poly-ferric chloride-polyepichlorohydrin-dimethylamine composite coagulant

A technology of polyepichlorohydrin and polyferric chloride is applied in the fields of environment and chemistry to avoid secondary dosing, reduce dosage and improve coagulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

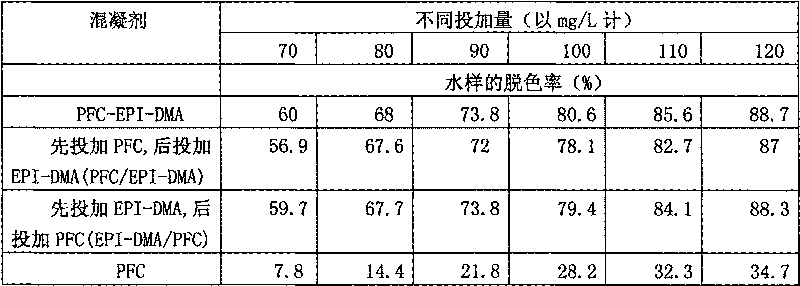

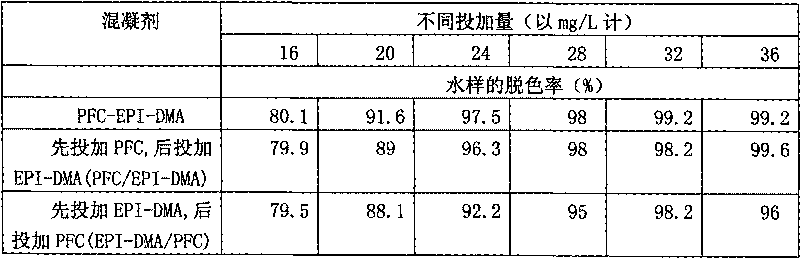

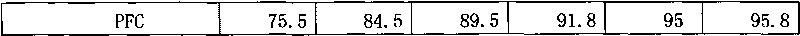

Image

Examples

Embodiment 1

[0020] A polymeric ferric chloride-polyepichlorohydrin-dimethylamine composite coagulant, its appearance is a dark reddish brown liquid, the mass fraction of Fe is about 7%, the alkalinity B value is 0.5, polyepoxychloride The mass fraction of propane-dimethylamine is 7%, and the viscosity η value is 850mPa·s.

[0021] The preparation technology of above-mentioned polyferric chloride-polyepichlorohydrin-dimethylamine composite coagulant is:

[0022] (1) Take 16.94g FeCl 3 ·6H 2 O solid in the beaker, add about 30ml of distilled water, under the stirring of magnetic stirrer until completely dissolving;

[0023] (2) Slowly add 1.66gNa 2 CO 3 Powder to alkalinity B value of 0.5;

[0024] (3) After the foam disappears, add the stabilizer Na 2 HPO 4 12H 2 O powder 1.80g;

[0025] (4) Continue stirring for about 3.5-4.5 hours until Na 2 HPO 4 12H 2 The O powder was completely dissolved to obtain a polyferric chloride solution. Then add 3.50g, polyepichlorohydrin-dimethy...

Embodiment 2

[0027] A polymeric ferric chloride-polyepichlorohydrin-dimethylamine composite coagulant, its appearance is a dark reddish brown liquid, the mass fraction of Fe is about 7%, the alkalinity B value is 0.5, polyepoxychloride The mass fraction of propane-dimethylamine is 7%, and the viscosity η value is 4200mPa·s.

[0028] The preparation technology of above-mentioned polyferric chloride-polyepichlorohydrin-dimethylamine composite coagulant is:

[0029] (1) Take 16.94g FeCl 3 ·6H 2 O solid in the beaker, add about 30ml of distilled water, under the stirring of magnetic stirrer until completely dissolving;

[0030] (2) Slowly add 1.66gNa 2 CO 3 Powder to alkalinity B value of 0.5;

[0031] (3) After the foam disappears, add the stabilizer Na 2 HPO 4 12H 2 O powder 1.80g;

[0032] (4) Continue stirring for about 4 hours until Na 2 HPO 4 12H 2 The O powder was completely dissolved to obtain a polyferric chloride solution. Then, add 3.50 g of polyepichlorohydrin-dimethyl...

Embodiment 3

[0034] A polymeric ferric chloride-polyepichlorohydrin-dimethylamine composite coagulant, the difference from Example 1 or 2 is that the mass fraction of polyepichlorohydrin-dimethylamine is 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com