Automotive air purifying filter element

An air purification and filter element technology, applied in the field of auto parts, can solve the problems of secondary pollution, emission mode restrictions, human body hazards, etc., and achieve the effect of efficient degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

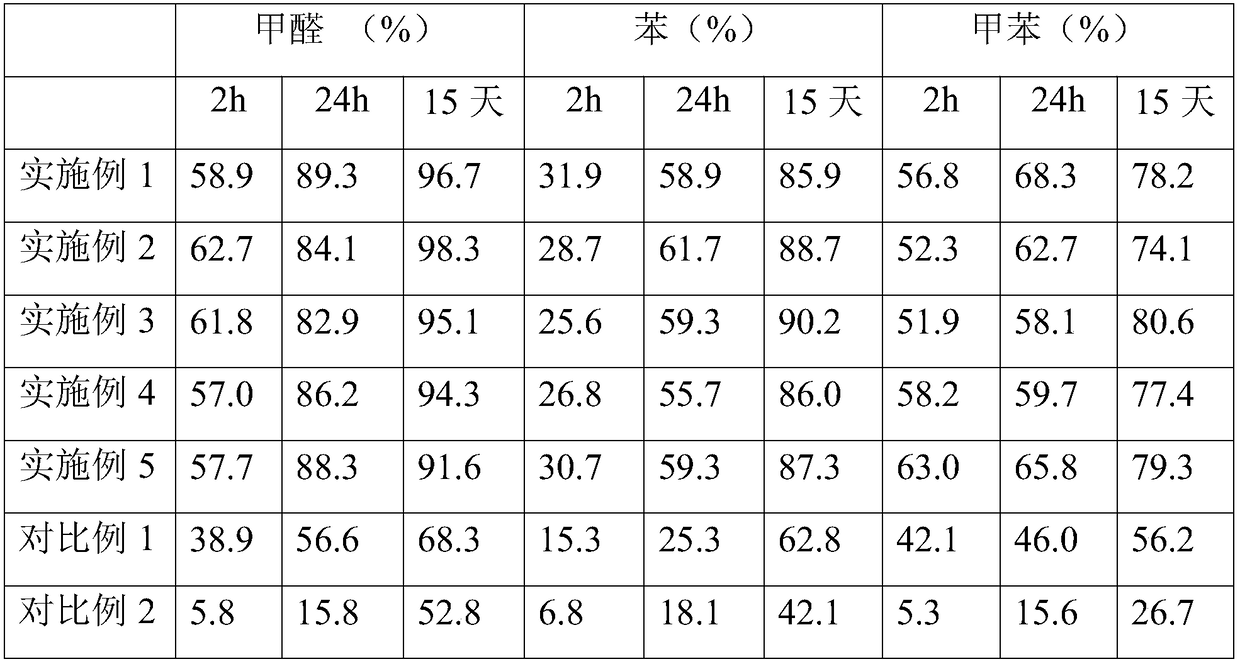

Examples

preparation example Construction

[0013] The present invention also provides a method for preparing the air purification filter element for vehicles, comprising the following steps:

[0014] (1) Mix organic silicate and organic titanate uniformly to obtain mixed solution A, mix cetyltrimethylammonium bromide and soluble metal salt in water uniformly, and then add to the mixed solution under stirring Add the mixed solution A to the system dropwise. After the dropwise addition, add a pH regulator to adjust the pH of the system to 5.3-6.2, then seal the mixed system at 100-160°C for 1-4 hours, and centrifugally wash and dry the product to obtain an intermediate product 1;

[0015] (2) After polyepichlorohydrin dimethylamine is uniformly dispersed in water, intermediate product 1 is added, ultrasonically reacted for 15-25 minutes, and then centrifugally washed and dried to obtain intermediate product 2;

[0016] (3) Ultrasonic disperse the intermediate product 2 and the polymer emulsion in the solvent evenly, the...

Embodiment 1

[0029] An air purification filter element for vehicles, comprising wood pulp fibers and a catalyst, the catalyst is made of the following parts by weight: 2.5 parts by weight of tetraethyl titanate, 6 parts by weight of tetrabutyl silicate, 0.012 parts by weight of nickel chloride 12 parts by weight of polyepichlorohydrin dimethylamine, 10 parts by weight of cetyltrimethylammonium bromide, 2.5 parts by weight of 4,4-oxobisbenzenesulfonyl hydrazide, 30 parts by weight of polyurethane emulsion (NORMIC -3150, the solid content is 30wt%), 5 parts by weight of hydrochloric acid (2M), 2 parts by weight of neopentyl glycol, and 30 parts by weight of ethanol.

[0030] The preparation method of the air purification filter element for vehicles, the steps are as follows:

[0031] (1) Tetraethyl titanate and tetrabutyl silicate are mixed uniformly to obtain mixed solution A, cetyltrimethylammonium bromide and nickel chloride are mixed uniformly in water, and then stirred to The mixed sol...

Embodiment 2

[0037] An air purification filter element for vehicles, comprising wood pulp fibers and a catalyst, the catalyst is made of the following parts by weight: 3.6 parts by weight of tetramethyl titanate, 10 parts by weight of tetrabutyl silicate, 0.015 parts by weight of sodium molybdate Parts, 8 parts by weight of polyepichlorohydrin dimethylamine, 12 parts by weight of cetyltrimethylammonium bromide, 2 parts by weight of azodicarbonamide, 45 parts by weight of polycaprolactone emulsion (CA0102, purchased from Dongguan Yingsheng Plastic Chemical Co., Ltd. (solid content: 60wt%), 3 parts by weight of hydrochloric acid (2M), 1 part by weight of 2-methyl-1,3-propanediol, 10 parts by weight of N,N-dimethylformamide .

[0038] The preparation method of the air purification filter element for vehicles, the steps are as follows:

[0039] (1) Mix tetramethyl titanate tetrabutyl silicate uniformly to obtain mixed solution A, mix cetyltrimethylammonium bromide and sodium molybdate in wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com