Ferric salt-polyepichlorohydrin-dimethylamine composite flocculant as well as preparation method and application thereof

A polyepichlorohydrin and composite flocculant technology, which is used in flocculation/sedimentation water/sewage treatment, etc., can solve problems such as aluminum biological toxicity, and achieve strong adsorption and bridging ability, high positive charge density, and wide range of dosage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

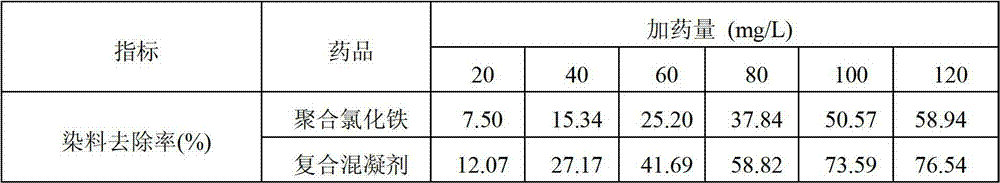

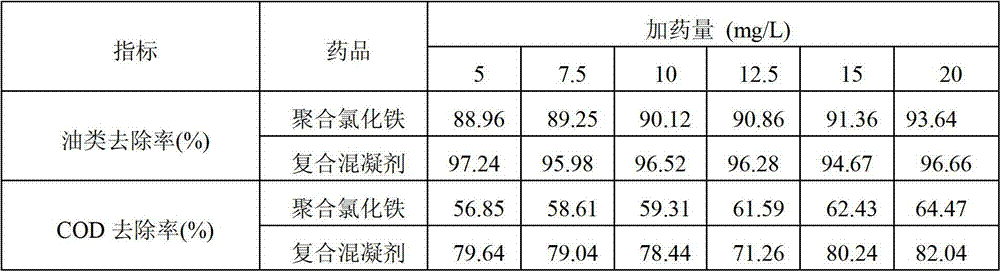

Examples

Embodiment 1

[0032] A kind of iron salt-polyepichlorohydrin-dimethylamine composite flocculant, the preparation steps are as follows:

[0033] (1) Weigh 29.02g FeCl 3 ·6H 2 O solid in a beaker, add 300mL distilled water, stir with a magnetic stirrer to make FeCl 3 ·6H 2 The O solid is completely dissolved to obtain a ferric chloride solution, and then continue to dissolve 4.73g of anhydrous sodium carbonate powder in (30-60) mL of distilled water under magnetic stirring to obtain a sodium carbonate solution, and add (3-5) mL / Add the sodium carbonate solution dropwise into the ferric chloride solution at a speed of 1 min, and control the degree of alkalinity to 0.5; after the foam disappears, continue to follow the Na 2 HPO 4 12H 2 O and FeCl 3 ·6H 2 Add stabilizer Na at a ratio of O molar ratio of 0.08 2 HPO 4 12H 2 O powder, Na 2 HPO 4 12H 2 After the O powder is completely dissolved, continue to stir and mature for 2 hours, dilute with distilled water until the mass concent...

Embodiment 2

[0037] An iron salt-polyepichlorohydrin-dimethylamine composite flocculant, the preparation steps are the same as in Example 1, the difference is that the distilled water in step (1) is diluted to a mass concentration of iron of 5g / L to obtain polyferric chloride solution, set aside.

Embodiment 3

[0039] An iron salt-polyepichlorohydrin-dimethylamine composite flocculant, the preparation steps are the same as in Example 1, the difference is that in step (1) distilled water is diluted to a mass concentration of iron of 15g / L to obtain polyferric chloride solution, set aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com