Oil reservoir protection accelerator and preparation method thereof

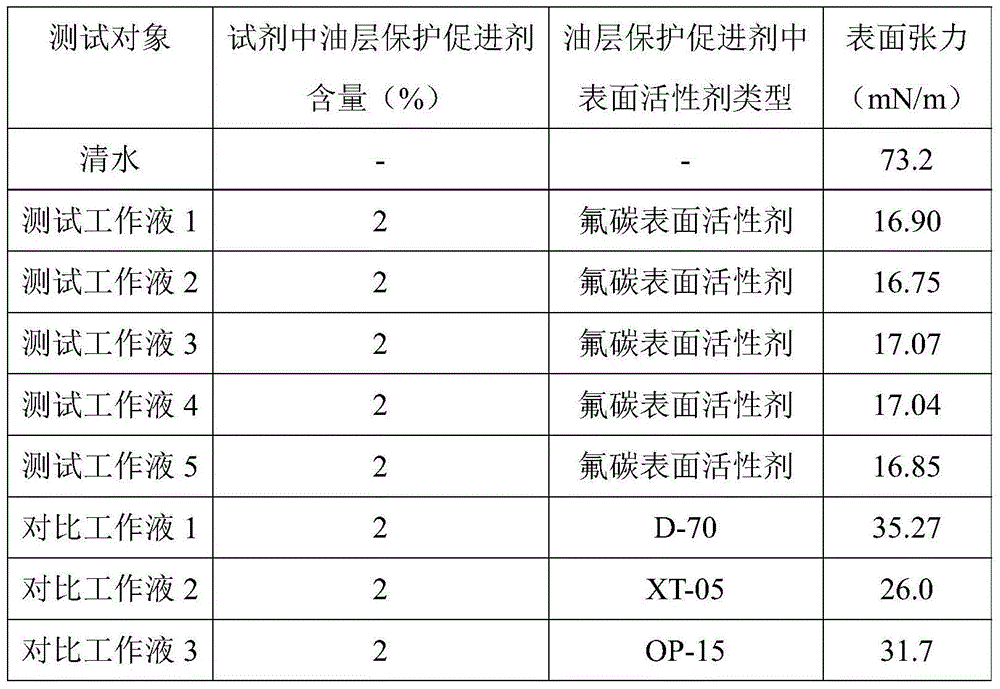

A technology for oil layer protection and accelerators, which is applied in the preparation of oil layer protection accelerators and in the field of oil layer protection accelerators. It can solve the problems that cannot meet the needs of low-porosity and low-permeability reservoir construction, the protection effect of oil layers is not obvious, and the state of reservoir balance is destroyed. To achieve the effect of improving coordination and compatibility, reducing water lock damage, and improving seepage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

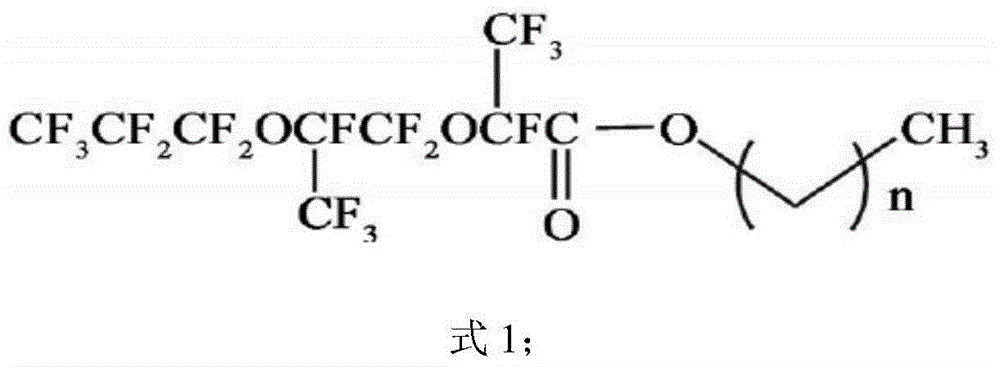

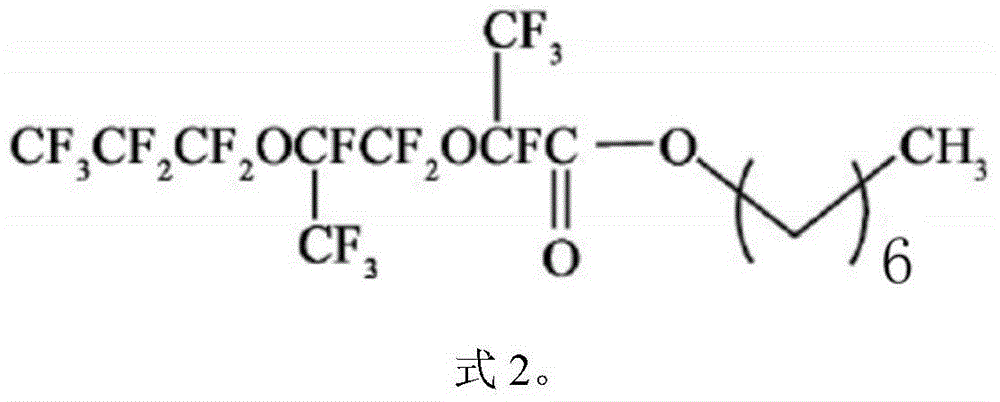

[0025] The oil layer protection accelerant of the present embodiment comprises the following components in weight percent: polyepichlorohydrin-dimethylamine 0.2%, ammonium chloride 0.5%, fluorocarbon surfactant 0.1%, ethanol 5%, and the balance is water.

[0026] The preparation method of the oil layer protection accelerator of the present embodiment comprises the following steps:

[0027] 1) Take the polyepichlorohydrin-dimethylamine, surfactant and ethanol in the formula quantity, add the water which accounts for 40% of the mass percentage of the oil layer protection accelerator, and mix evenly to obtain the mixture;

[0028] 2) Take the mixture obtained in step 1), add the formula amount of ammonium chloride and the remaining water, mix evenly, and obtain.

Embodiment 2

[0030] The oil reservoir protection accelerant of the present embodiment comprises the following components by weight: polyepichlorohydrin-dimethylamine 0.2%, ammonium chloride 1.0%, fluorocarbon surfactant 0.2%, ethanol 5%, and the balance is water.

[0031] The preparation method of the oil layer protection accelerator of the present embodiment comprises the following steps:

[0032] 1) Take the polyepichlorohydrin-dimethylamine, surfactant and ethanol in the formula quantity, add the water which accounts for 45% of the mass percentage of the oil layer protection accelerator, and mix evenly to obtain the mixture;

[0033] 2) Take the mixture obtained in step 1), add the formula amount of ammonium chloride and the remaining water, mix evenly, and obtain.

Embodiment 3

[0035] The oil reservoir protection accelerant of the present embodiment comprises the following components by weight percentage: polyepichlorohydrin-dimethylamine 0.4%, ammonium chloride 1.0%, fluorocarbon surfactant 0.2%, ethanol 10%, and the balance is water.

[0036] The preparation method of the oil layer protection accelerator of the present embodiment comprises the following steps:

[0037] 1) Take the polyepichlorohydrin-dimethylamine, surfactant and ethanol in the formula quantity, add the water which accounts for 50% by mass of the oil layer protection accelerator, and mix evenly to obtain the mixture;

[0038] 2) Take the mixture obtained in step 1), add the formula amount of ammonium chloride and the remaining water, mix evenly, and obtain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com