Multi-grain-size 7-series aluminum alloy composite material and preparation method thereof

A technology for composite materials and aluminum alloys, which is applied in the field of multi-grain-scale 7-series aluminum alloy composite materials and its preparation, can solve the problems of general anti-fading effect of refiners, cumbersome and complicated preparation procedures, and serious plastic loss, etc. Good chemical effect, wide applicability, and the effect of improving surface wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Step (1): Prepare bar raw materials: aluminum ingot with purity ≥99.7%, 5.5wt.% zinc powder, 1.5wt.% magnesium powder, 0.1wt.% chromium powder of 50-100 μm, (for the preparation of Al-5.5Zn - 1.5Mg-0.1Cr aluminum alloy matrix material) 0.1wt.% and 1wt.% Al-TiC (B) seed alloy rod two small pieces, silicon block with purity ≥ 99.7%.

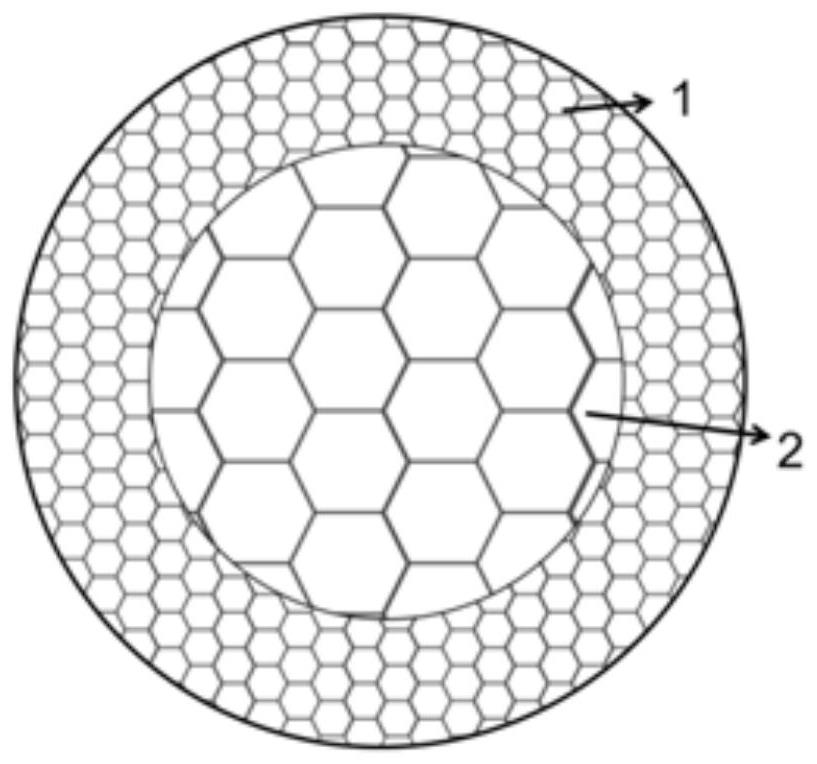

[0043] Step (2): Prepare the inner layer and the outer layer casting mold: the inner diameter of the inner layer mold is 10mm, and the length is 0.11m. The outer mold is a hollow ring with a length of 0.1m. The outer diameter of the solid part of the ring is 10mm, and the inner diameter of the outer hollow part is 13mm.

[0044] Step (3): Prepare rods: Mix all kinds of powders evenly. Put the aluminum ingot into the vacuum melting furnace, raise the temperature to 720°C in 70 minutes, and keep it warm for one hour. After taking out the molten aluminum and stirring evenly, add the weighed 5.5wt.% zinc powder, 1.5wt.% magnesium powder, 0.1w...

Embodiment 2

[0049] Step (1): Prepare bar raw materials: aluminum ingot with purity ≥ 99.7%, 3wt.% zinc powder, 3wt.% magnesium powder, 5wt.% silicon block (for preparing Al-3Zn-3Mg-5Si aluminum Alloy base material), 0.1wt.% and 1.5wt% Al-TiC (B) seed alloy bar two small sections, purity ≥ 99.7% silicon block.

[0050] Step (2): Prepare a plate casting mold: length 0.2m, width 0.2m, thickness 10mm.

[0051] Step (3): Preparation of plates: Mix all kinds of powders evenly. Put the aluminum ingot into the vacuum melting furnace, raise the temperature to 720°C in 70 minutes, and keep it warm for one hour. After taking out molten aluminum and stirring evenly, add weighed 3wt.% zinc powder, 3wt.% magnesium powder, 5wt.% silicon block, 0.1wt.% Al-TiC(B) seed alloy rod. Stir evenly, put it into the melting furnace and keep it warm for 30 minutes. After the mold is preheated to 200-300°C, pour it into the mold for preparing plate-shaped materials, take it out after water cooling, and clean the s...

Embodiment 3

[0055] Step (1): Prepare rod raw materials: 7005 aluminum alloy, 0.1wt.%, 0.4wt% and 2wt% Al-TiC(B) seed crystal alloy rods in three sections.

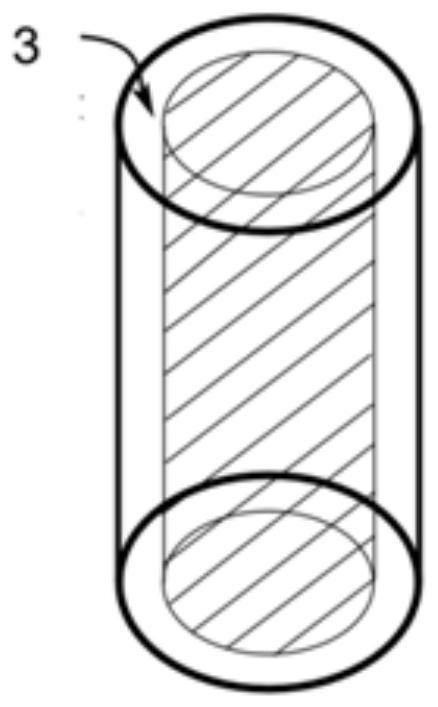

[0056] Step (2): Prepare the casting mold for the inner layer, the middle layer and the outer layer: the inner diameter of the inner layer mold is 30mm, and the length is 0.5m. The middle layer mold is used to cast the middle layer hollow round tube, the length is 0.49m, the inner diameter of the round tube is 30mm, and the outer diameter is 40mm. The outer layer mold is used to cast the outer layer hollow round tube, the length is 0.48m, the inner diameter of the round tube is 40mm, and the outer diameter is 50mm.

[0057] Step (3): Prepare rods: put the 7005 aluminum alloy into a vacuum melting furnace, raise the temperature to 720° C. in 70 minutes, and keep the temperature for one hour. After taking out molten aluminum and stirring evenly, 0.1wt.% Al-TiC(B) seed crystal alloy rod. Stir evenly, put it into a smelting furnace and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com