Activated composite absorption air filter core and preparation method thereof

An air filter element and composite adsorption technology, applied in the field of air purification, can solve the problem of not being able to purify organic gases, etc., and achieve the effect of excellent surface catalytic activity and high specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

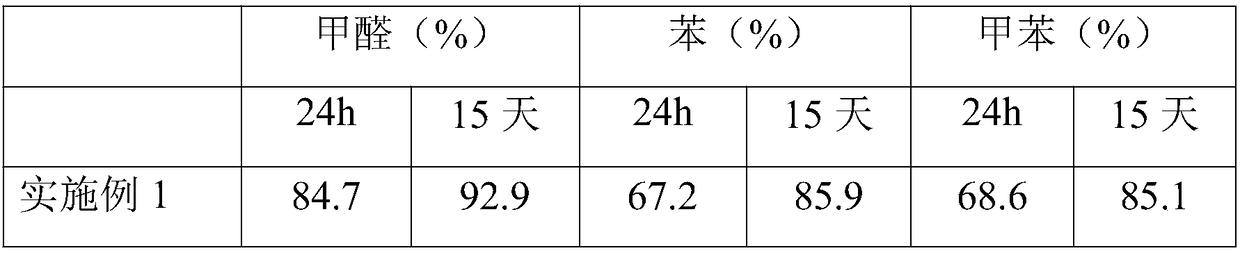

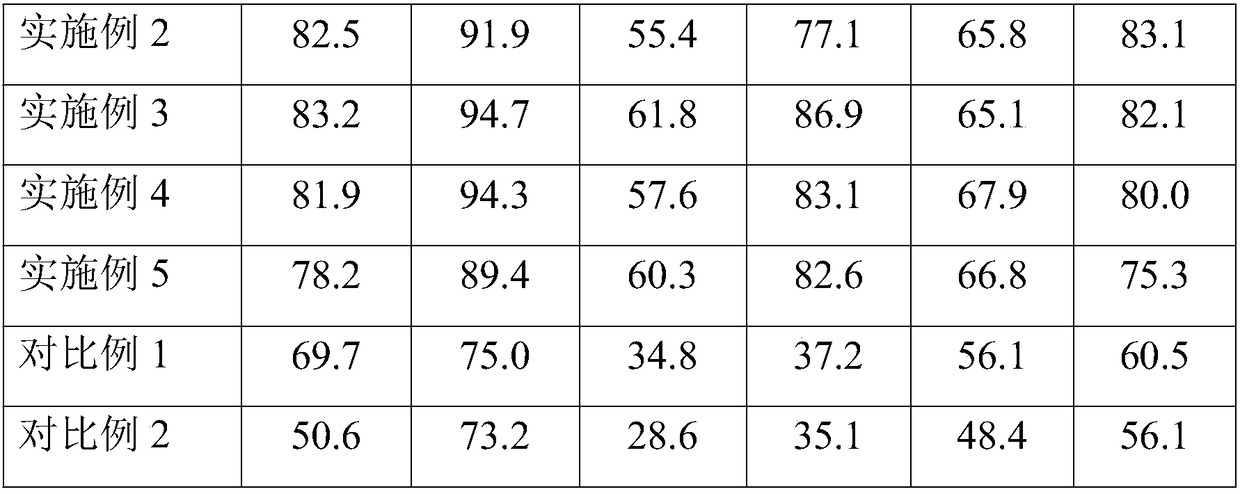

Examples

preparation example Construction

[0017] The present invention also provides a preparation method of the activated composite adsorption air filter, comprising the following steps:

[0018] (1) Mix organic silicate and organic titanate evenly to obtain mixed sol A, then add the zeolite-like imidazole skeleton material into mixed sol A, and ultrasonically disperse for 20 to 45 minutes to obtain mixed sol B, and then Add cetyltrimethylammonium bromide solution dropwise to the mixed sol B. After the dropwise addition, add a pH regulator to adjust the pH of the system to 5.3-6.2, and then seal the mixed system at 100-160°C for 1 ~4h, the product was washed and dried by centrifugation to obtain intermediate product 1;

[0019] (2) After polyepichlorohydrin dimethylamine is uniformly dispersed in water, intermediate product 1 is added, ultrasonically reacted for 15-25 minutes, and then centrifugally washed and dried to obtain intermediate product 2;

[0020] (3) Roasting the intermediate product 2 at 300-500° C. for...

Embodiment 1

[0027] An activated composite adsorption air filter element is made of the following parts by weight: 300 parts by weight of wood pulp fiber, 28 parts by weight of zeolite-like imidazole framework material (Zn-ZIF), 14 parts by weight of tetraethyl titanate, silicic acid 2 parts by weight of tetrabutyl ester, 20 parts by weight of polyepichlorohydrin dimethylamine, 10 parts by weight of cetyltrimethylammonium bromide, 5 parts by weight of 2M hydrochloric acid, 30 parts by weight of N,N-dimethylformamide share.

[0028] The preparation method of the activated composite adsorption type air filter element, the steps are as follows:

[0029] (1) Dissolve zinc chloride and 2-methylimidazole in N, N-dimethylformamide (the molar ratio of zinc chloride and 2-methylimidazole is 1:8), pour the zinc chloride solution into the 2-methylimidazole solution, and stirred at 50°C for 12 hours, washed, centrifuged, and dried to obtain the zeolite-like imidazole framework material (Zn-ZIF);

[...

Embodiment 2

[0035]An activated composite adsorption air filter element is made of the following parts by weight: 400 parts by weight of wood pulp fiber, 20 parts by weight of zeolite-like imidazole framework material (Zn-ZIF), 5 parts by weight of tetraethyl titanate, silicic acid 1 part by weight of tetrabutyl ester, 8 parts by weight of polyepichlorohydrin dimethylamine, 12 parts by weight of cetyltrimethylammonium bromide, 8 parts by weight of 2M hydrochloric acid, and 50 parts by weight of tetrahydrofuran.

[0036] The preparation method of the activated composite adsorption type air filter element, the steps are as follows:

[0037] (1) Dissolve zinc chloride and 2-methylimidazole in tetrahydrofuran (the molar ratio of zinc chloride and 2-methylimidazole is 1:10), and pour the zinc chloride solution into the 2-methylimidazole solution , and stirred at 45°C for 10 hours, washed, centrifuged, and dried to obtain the zeolite-like imidazole framework material;

[0038] Mix tetrabutyl si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com