Wet oxidation catalyst and preparation method thereof

A wet oxidation and catalyst technology, used in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as low COD removal efficiency and reduce organic matter content. , the effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

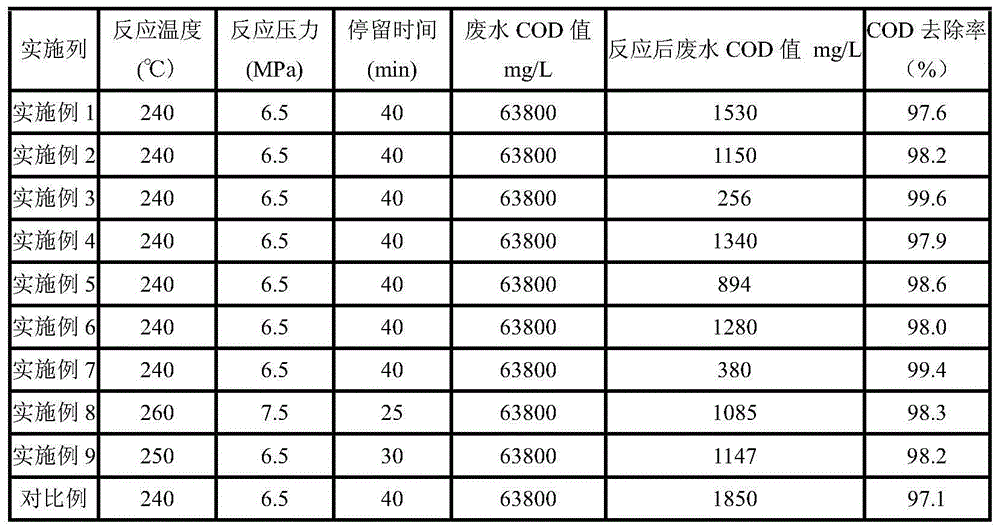

Examples

Embodiment 1

[0030] 1. Catalyst preparation

[0031] In terms of weight ratio, TiO 2 :CeO 2 :Ru is 98.8:0.8:0.4. The preparation method of catalyst is: 1) preparation of carrier: 240g nano TiO 2 Powder, 1.95g nanometer CeO 2 Powder, 80g of water and 4g of carboxymethyl cellulose were mixed and kneaded for 2 hours, and extruded. After the molded product was dried at room temperature, it was calcined at 700°C for 2 hours; 2) loaded precious metal: 199.0g molded carrier was impregnated at room temperature with 2.16g RuCl hydrate 3 overnight, dried at 80°C, and then reduced for 4 hours in a hydrogen atmosphere (hydrogen-nitrogen mixture with a hydrogen content of 4%) at 400°C to obtain a noble metal-supported catalyst W-01. The formulation of the catalyst is shown in Table 1.

[0032] 2. Catalyst evaluation

[0033] Using industrial acrylic acid wastewater as raw material, the COD value of the wastewater is 63,800mg / L. Wastewater is mixed with oxygen and passed through a 125mL fixed-be...

Embodiment 2

[0035] 1. Catalyst preparation

[0036] In terms of weight ratio, TiO 2 :Nd 2 o 3 :Ru is 98.4:1.2:0.4. The preparation method of catalyst is: 1) preparation of carrier: 240g nano TiO 2 Powder, 2.90g nanometer Nd 2 o 3 Powder, 80g of water and 4g of carboxymethyl cellulose were mixed and kneaded for 2 hours, and extruded. After the molded product was dried at room temperature, it was calcined at 700°C for 2 hours; 2) loaded precious metal: 199.0g molded carrier was impregnated at room temperature with 2.16g RuCl hydrate 3 in the aqueous solution overnight, dried at 80°C, and then reduced for 4 hours under a hydrogen atmosphere (hydrogen-nitrogen mixture with a hydrogen content of 4%) at 400°C to obtain a noble metal-supported catalyst W-02. The formulation of the catalyst is shown in Table 1.

[0037] 2. Catalyst evaluation

[0038] Using industrial acrylic acid wastewater as raw material, the COD value of the wastewater is 63,800mg / L. Wastewater is mixed with oxygen ...

Embodiment 3

[0040] 1. Catalyst preparation

[0041]In terms of weight ratio, TiO 2 :CeO 2 :Nd 2 o 3 :Ru is 98.4:0.4:0.8:0.4. The preparation method of catalyst is: 1) preparation of carrier: 240g nano TiO 2 Powder, 0.98gCeO 2 Powder, 1.92g nanometer Nd 2 o 3 Powder, 80g of water and 4g of carboxymethyl cellulose were mixed and kneaded for 2 hours, and extruded. After the molded product was dried at room temperature, it was calcined at 700°C for 2 hours; 2) loaded precious metal: 199.0g molded carrier was impregnated at room temperature with 2.16g RuCl hydrate 3 overnight, dried at 80°C, and then reduced for 4 hours in a hydrogen atmosphere (hydrogen-nitrogen mixture with a hydrogen content of 4%) at 400°C to obtain a noble metal-supported catalyst W-03. The formulation of the catalyst is shown in Table 1.

[0042] 2. Catalyst evaluation

[0043] Using industrial acrylic acid wastewater as raw material, the COD value of the wastewater is 63,800mg / L. Wastewater is mixed with oxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com