Method for recovering and purifying terephthalic acid in alkali-minimization waste liquor

A technology for terephthalic acid and alkali reduction waste liquid, which is applied in the preparation of carboxylate, separation/purification of carboxylic acid compounds, etc. Good social and economic benefits, small equipment investment scale, and the effect of reducing COD content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

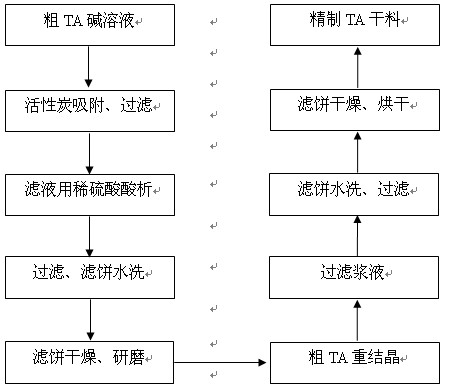

Method used

Image

Examples

Embodiment 1

[0039] Add activated carbon to the alkali reduction waste liquid and stir at room temperature for 3-5 hours, add 1 g of activated carbon to 1 L of waste liquid, absorb organic matter in the solution, and initially remove colored pigments and most of the organic impurities. Then, the activated carbon and small particles in the waste liquid are filtered through a microporous filter, and the filtrate is a sodium terephthalate solution. The filtrate is neutralized with 5~20% dilute acid (one or more of hydrochloric acid, sulfuric acid, phosphoric acid, acetic acid mixed acid solution), stirring constantly, the solution slowly becomes a white suspension, add acid to the solution pH When the value is lower than 3, the white solid is filtered out, and the filtrate has no obvious change after adding dilute acid, and the acid precipitation is complete. Acid-analyzed solids were washed with water, filtered, dried, and ground to obtain crude terephthalic acid.

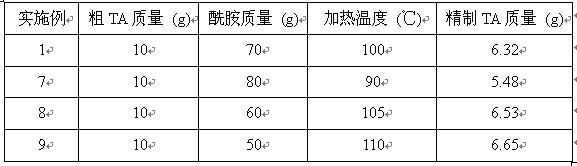

[0040] Add 10 g of crude...

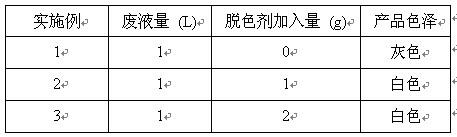

Embodiment 2

[0042] Treat the alkali reduction waste liquid in a manner similar to Example 1, except that no activated carbon adsorbent is added in this example, and the relevant analysis data results are compared in Table 1.

Embodiment 3

[0044] The alkali reduction waste liquid was treated in a manner similar to Example 1, except that 2 g of activated carbon was added to 1 L of waste liquid in this example, and the relevant analysis data results were compared in Table 1.

[0045] Table 1 The effect of the amount of decolorizing agent added on the color of the product

[0046]

[0047] As can be seen from the results of comparative examples 1 to 3, without adding decolorizer, the product color is dark, but the same 1 L waste liquid plus 1 g decolorizer is compared with adding 2 g decolorizer, the color of the product obtained is not significantly improved, and the reclaimed The color index of terephthalic acid is very good, so it is more appropriate to decolorize 1 L of waste liquid with 1 g of activated carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com