Pretreatment method for waste emulsion

A waste emulsion and combined treatment technology, applied in chemical instruments and methods, special compound water treatment, filtration treatment, etc., can solve the problems of difficult biodegradation, difficult to obtain treatment effect by demulsification method, and achieve simple operation and no production. The effect of secondary pollution and B/C ratio improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

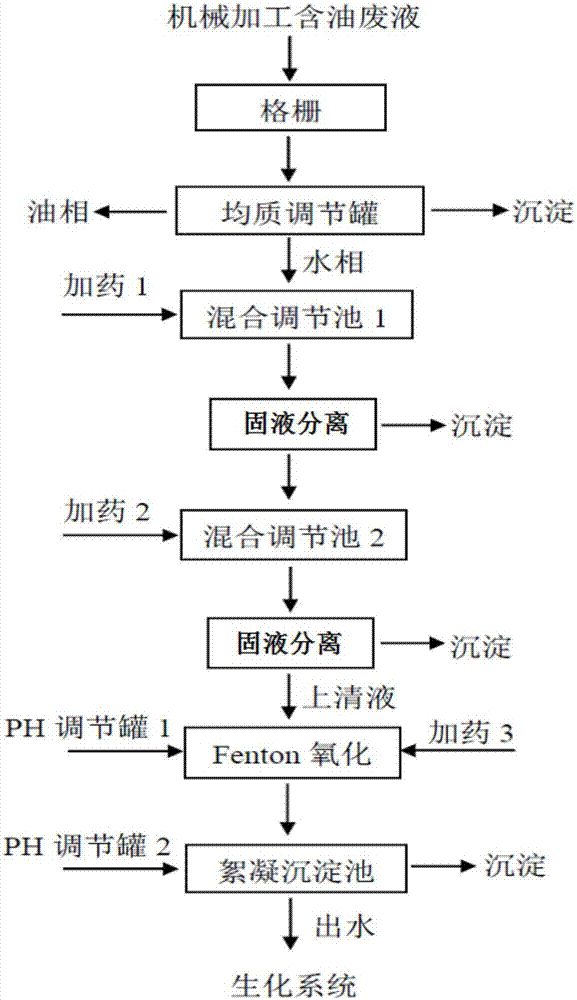

Image

Examples

Embodiment 1

[0036] The present embodiment processes No. 1 tank waste emulsion according to the following steps:

[0037] (1) Pass the waste emulsion of No. 1 tank through the middle grid to remove large particles in the water;

[0038] (2) Subsequently, the waste emulsion is introduced into a homogeneous regulating tank, and the waste emulsion is separated into three phases of oil, water and sand;

[0039] (3) Introduce the separated water phase into the mixing adjustment tank 1, add 1.5g / L CaCl respectively 2 and 1.5g / L polyferric sulfate (PFS) for primary demulsification; CaCl 2 Dosing in the form of a solution with polyferric sulfate (PFS).

[0040] (4) The waste water after the demulsification is introduced into the solid-liquid separation device for solid-liquid separation, so that the generated solid precipitate is separated;

[0041] (5) Introduce the supernatant into the mixing adjustment tank 2 again, add a composite demulsifier and PAM for secondary demulsification; the compo...

Embodiment 2

[0047] The present embodiment processes No. 2 tank waste emulsion according to the following steps:

[0048] (1) Pass the waste emulsion of No. 2 tank through the middle grid to remove large particles in the water;

[0049] (2) Subsequently, the waste emulsion is introduced into a homogeneous regulating tank, and the waste emulsion is separated into three phases of oil, water and sand;

[0050] (3) Introduce the separated water phase into the mixing adjustment tank 1, add 1.5g / L CaCl respectively 2 and 1.5g / L polyferric sulfate (PFS) for primary demulsification; CaCl 2 Dosing in the form of a solution with polyferric sulfate (PFS).

[0051] (4) The waste water after the demulsification is introduced into the solid-liquid separation device for solid-liquid separation, so that the generated solid precipitate is separated;

[0052] (5) Introduce the supernatant into the mixing adjustment tank 2 again, add a composite demulsifier and PAM for secondary demulsification; the compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com