Method for separating organic matter impurities from brine waste of coal chemical industry and separating salt by utilizing membrane method

A technology of coal chemical industry and wastewater, applied in the field of coal chemical industry, can solve the problems of unseparated salt components, environmental impact, and difficulty in ensuring the stable operation of the terminal crystallization process, and achieve the effect of improving purity and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

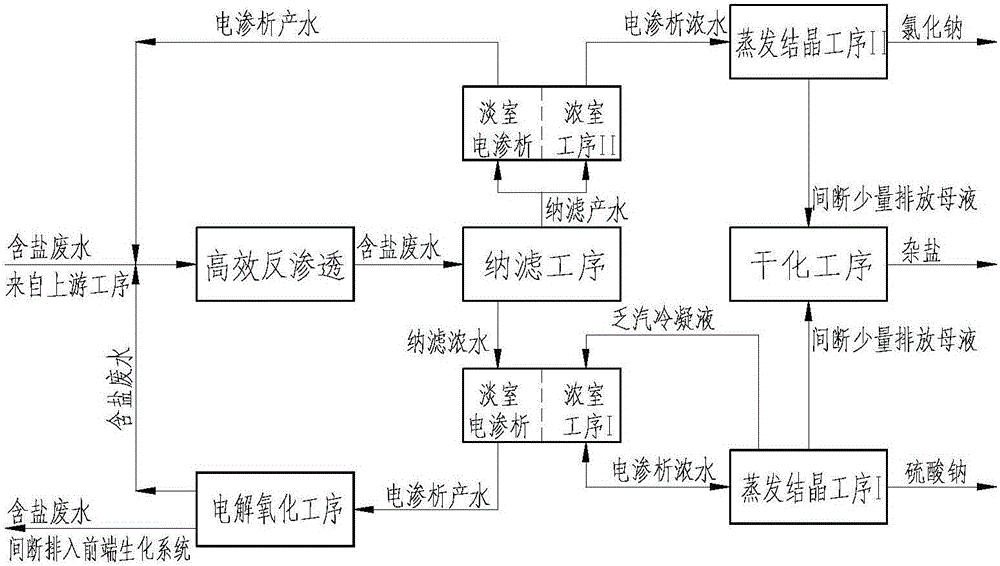

Image

Examples

Embodiment Construction

[0037] The saline wastewater flow rate of a factory's return water station is about 200m 3 / h, the TDS content is about 20000mg / L, the COD content is about 280mg / L, and the salt-nitrate ratio is about 1.71. 3 / h, TDS about 50000mg / L is sent into the nanofiltration system.

[0038] After being treated by the nanofiltration system, the amount of water on the concentrated water side of the nanofiltration is about 16m 3 / h, the total salt content is about 110g / L, the salt-to-nitrate ratio is about 0.38, and the COD content is about 2800mg / L; 3 / h, the salt content is about 200g / L, and basically does not contain COD, it is sent to the evaporation crystallization process I, and finally the sodium sulfate product is about 1.2t / h. Electrodialysis process I produces about 16m of water 3 / h, the total salt content is about 10g / L, and the COD content is about 2800mg / L, then it is sent to the electrolytic oxidation process for treatment, and the treated saline wastewater is returned to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com