Enzyme preparation and application thereof

A technology of enzyme preparation and compound enzyme preparation, which is applied in the fields of textiles and papermaking, fiber treatment, biochemical fiber treatment, etc., can solve the problems of large steam consumption, reduce processing difficulty, and large power emission, and achieve consumption saving and stable Good performance, the effect of reducing COD content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

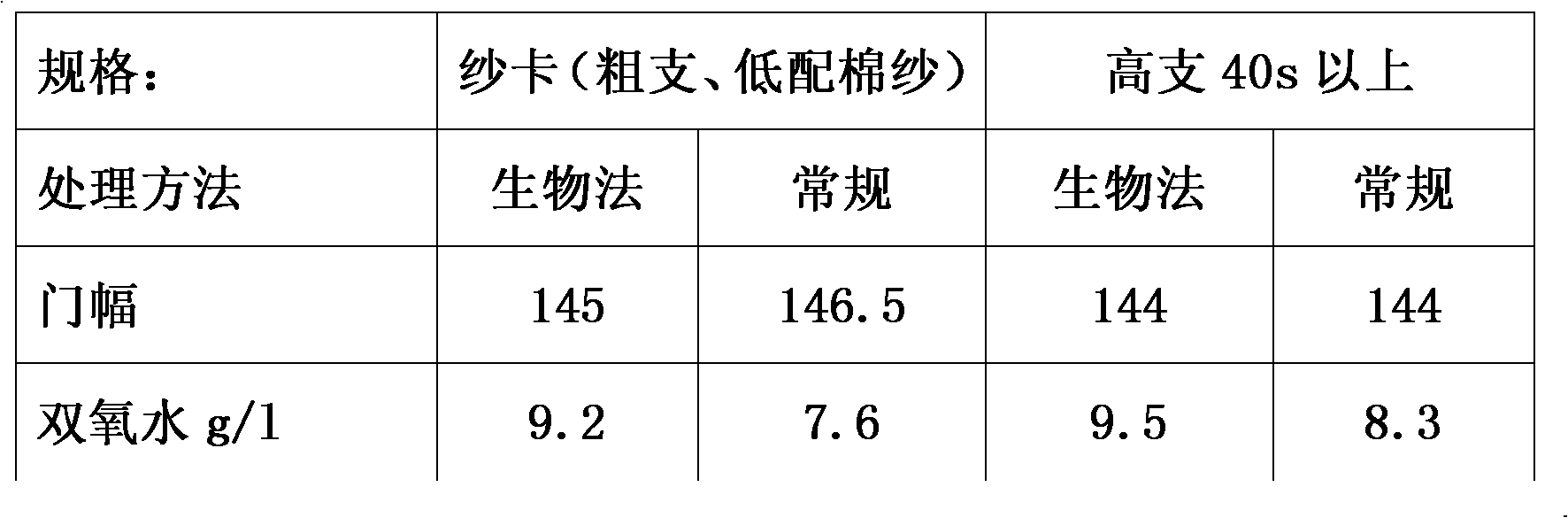

[0036] An enzyme preparation comprising 0.5-20 g / L cottonseed hull removal enzyme, 0.2-20 g / L amylase, 0.5-10 g / L cellulase, and 1-100 g / L emulsified penetrant with a pH of 4-7 Compound enzyme preparation.

[0037] The preferred solution is: it is a compound with a pH of 4-7 containing 2-10g / L cottonseed hull removal enzyme, 2-5g / L amylase, 0.5-3g / L cellulase, and 6-20g / L emulsified penetrant Enzyme.

[0038] 0.5-10 grams of Tween 80 and 0.5-10 grams of sodium tripolyphosphate are added per kilogram of the enzyme preparation. Also add 1 gram of Tween 80 and 1 gram of sodium tripolyphosphate per kilogram of the enzyme preparation, which is more optimal.

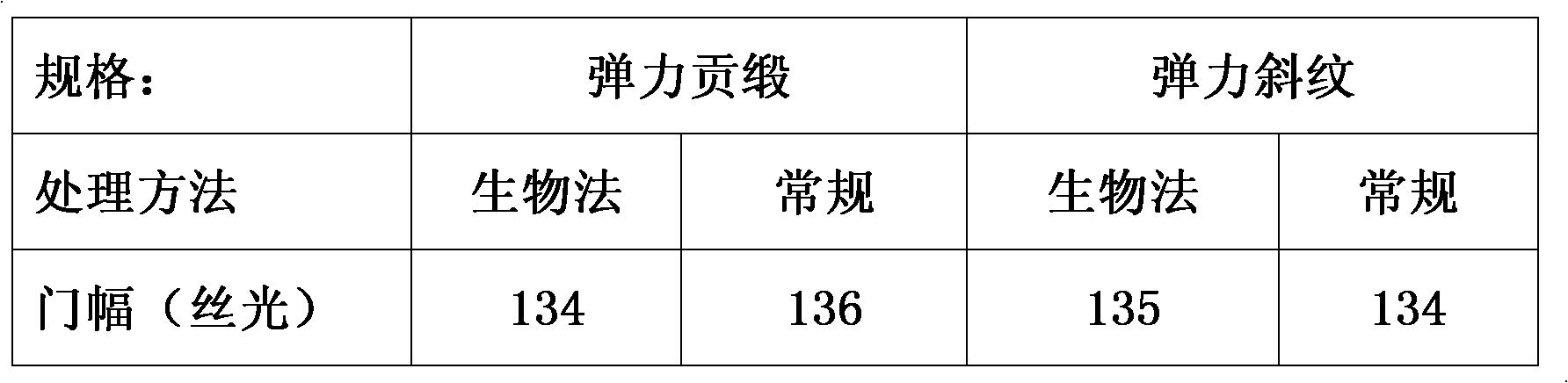

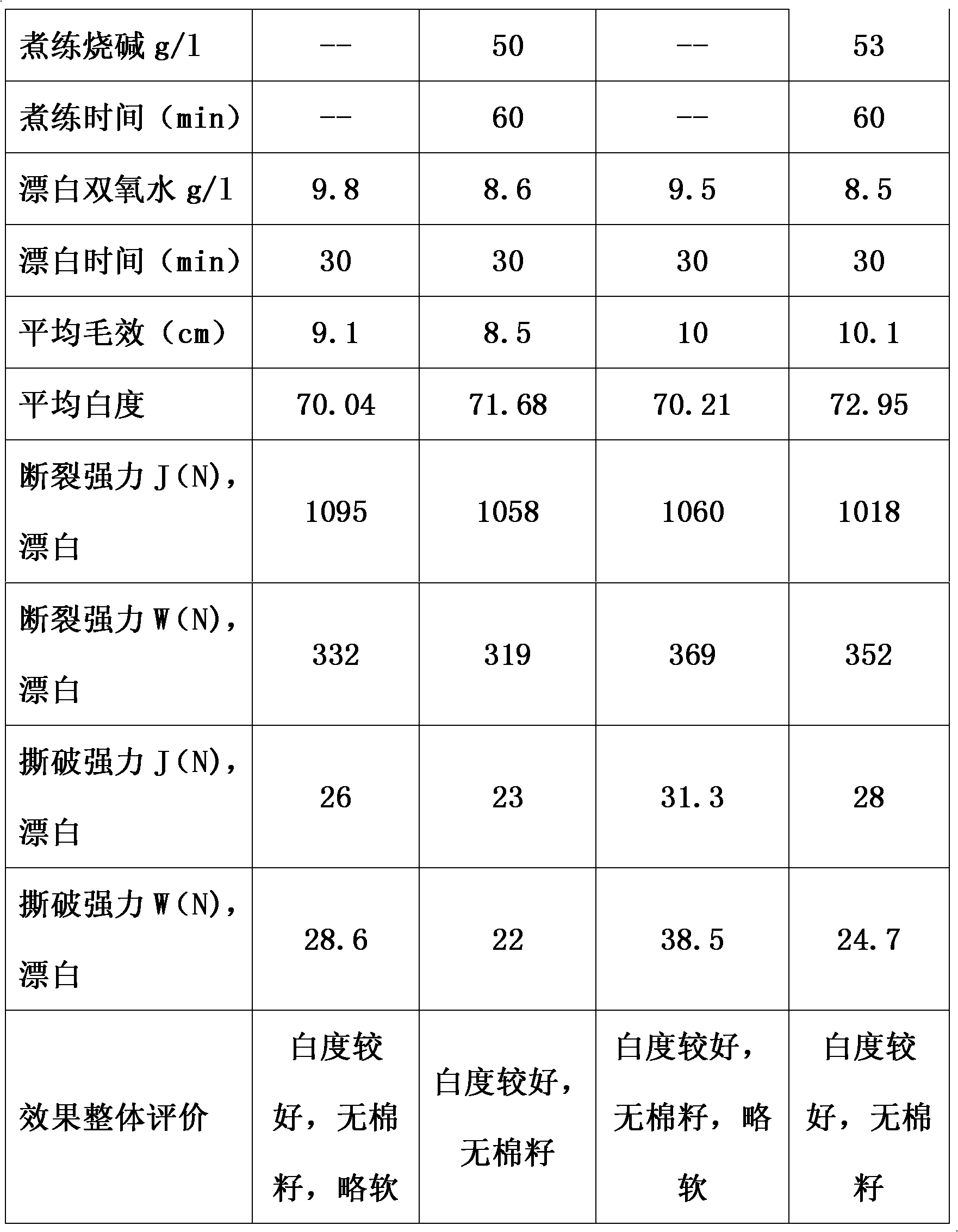

[0039] The textile is treated by using the enzyme preparation to replace the desizing, singeing and scouring processes in the pretreatment process of the textile.

[0040] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com