Method for directly building tailing ponds without filling positions above goaf

A technology for gobs and tailings ponds, applied in filling, mining equipment, earth cube drilling and mining, etc., can solve problems such as loss, difficulties in land acquisition and relocation of farmers, difficulty in land acquisition and tailings ponds, etc., to achieve a comprehensive level The effect of wide, long-term experience, and strong overall concept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further describe the present invention, a method of directly building a tailings pond without filling the goaf will be further described in detail below in conjunction with the accompanying drawings and embodiments.

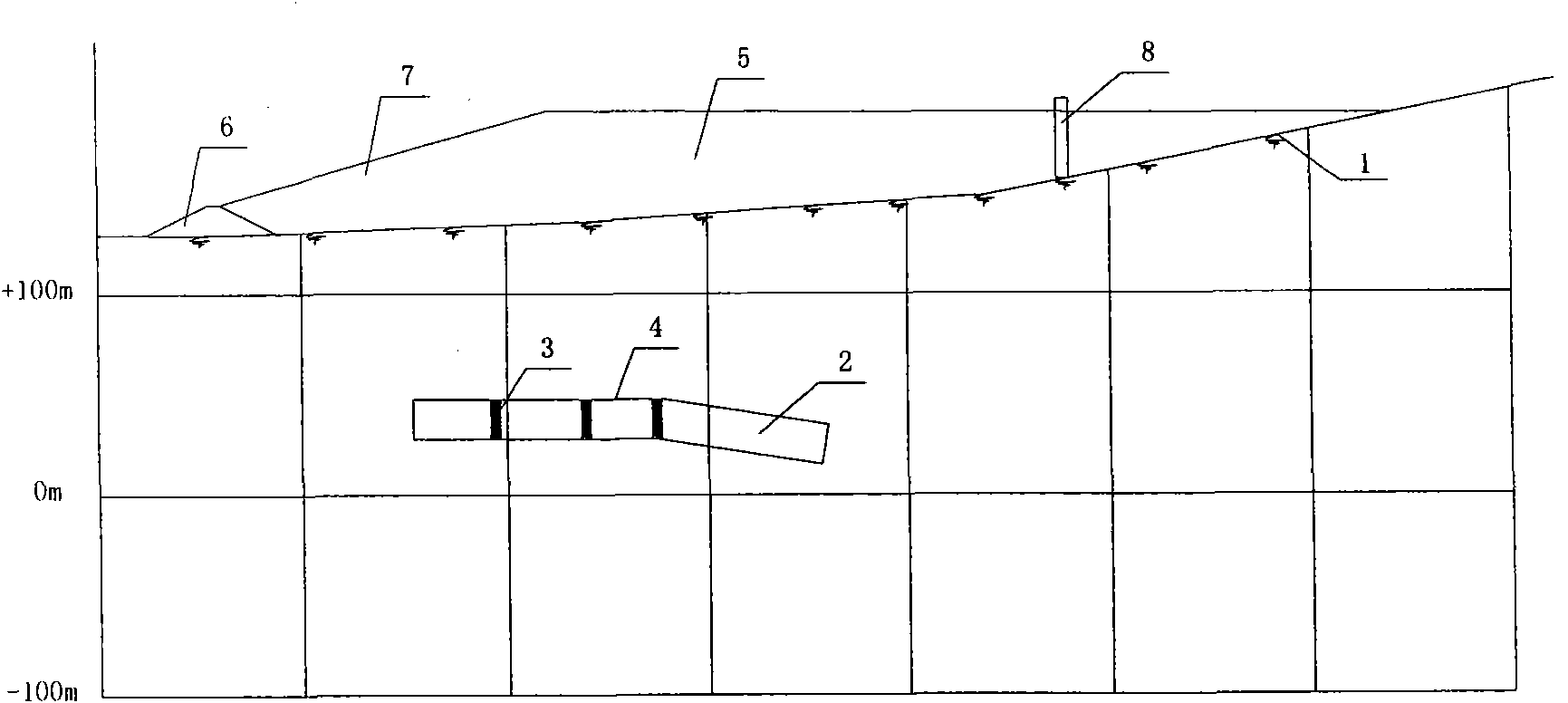

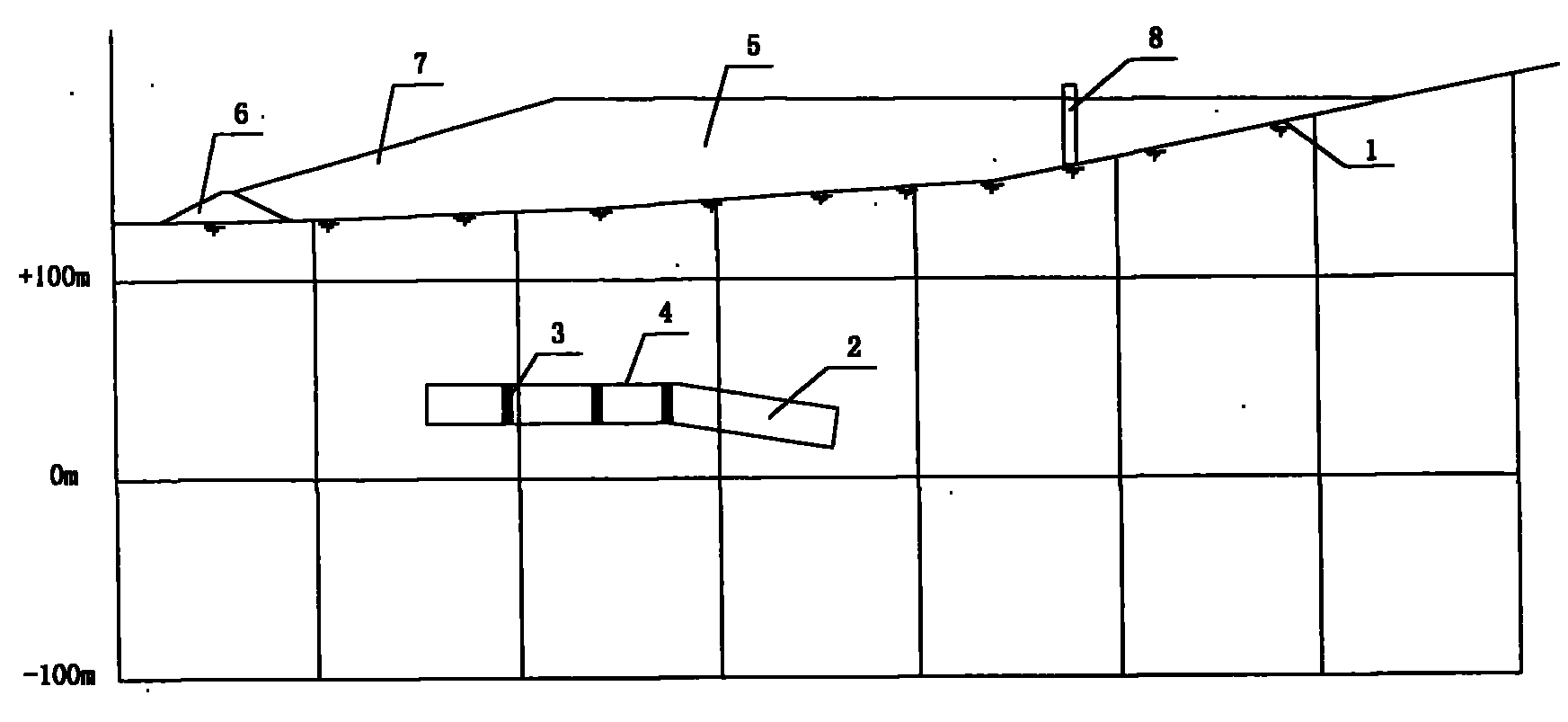

[0028] figure 1 Shown is a longitudinal projection diagram of the principle and layout of a method of directly building a tailings pond without filling the goaf in the present invention. The reference signs are:

[0029] 1-surface; 2-goaf; 3-pillar; 4-roof overburden; 5-tailing pond; 6-initial dam; 7-tailings accumulation dam; 8-drainage system.

[0030] Depend on figure 1 Shown is the principle and layout of a method of directly building tailings ponds above the goaf without filling the goaf according to the present invention. The longitudinal projection diagram shows:

[0031] Through the investigation of the goaf 2 and the rock mechanics test of the ore pillar 3, the roof overlying rock was divided into 4 blocks and the irregular column i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com