City sewage sludge reclamation processing and utilization method

A municipal sludge recycling technology, applied in the field of recycling municipal sludge, can solve the problems of increased process links, increased pulping costs, unsuitable for large-scale and commercial promotion and application, and saves coal and water Significant effect on resource and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

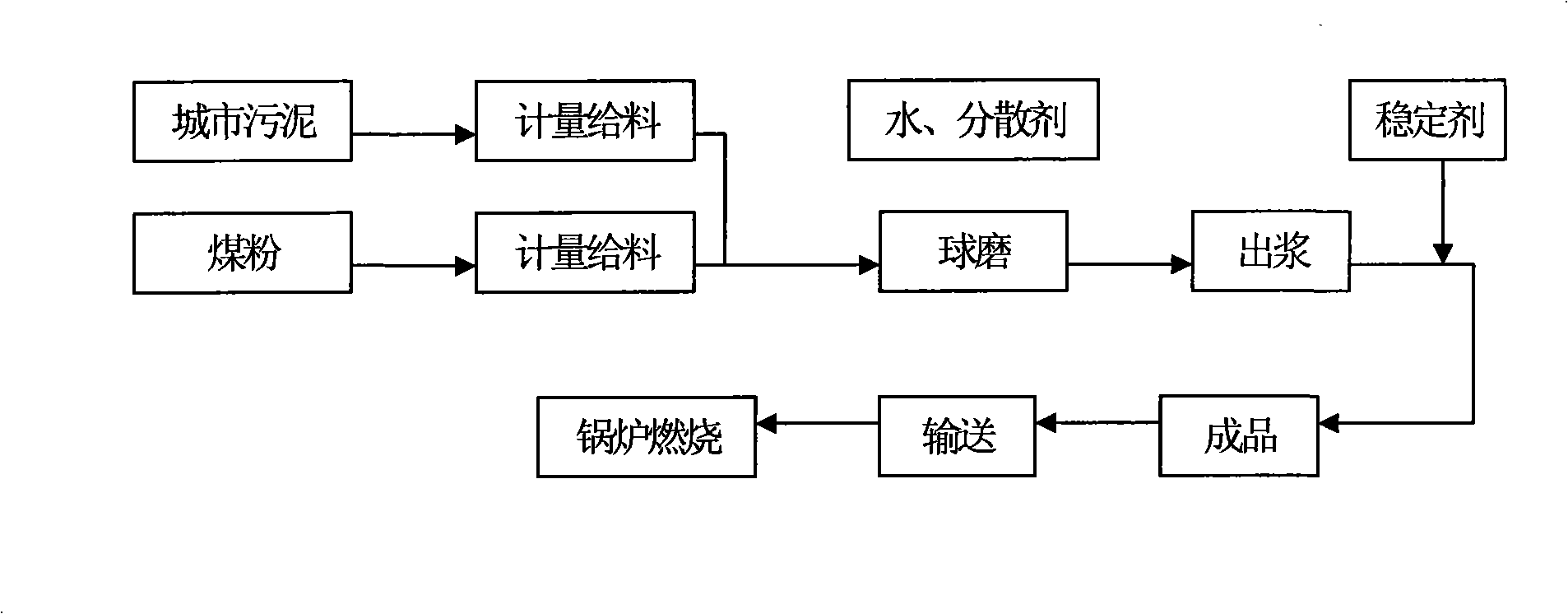

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Use a city with a calorific value of 26.82MJ / kg, a volatile content of 33.61%, a fixed carbon of 54.19%, an ash content of 10.49%, and a coal with a moisture content of 78.50%, volatile content of 37.25%, fixed carbon of 5.44%, and ash content of 57.31% sludge.

[0017] Mix 5 parts of municipal sludge and 62 parts of coal by ball milling, add 0.5 parts of lignosulfonate dispersant and 32.5 parts of water during the ball milling process to obtain a particle size greater than 300 microns with a content of 0.07% and a content of less than 75 microns It is 81.86% of the crude sludge coal water slurry; after the slurry is discharged, it is allowed to stand for 10 minutes, and 0.6% to 0.7% of the total weight of the crude sludge coal water slurry is added to obtain a concentration of 61.95% and ash content. The finished product coal water slurry with 7.16%, 0.40% sulfur, 37.02% volatile and 17.44MJ / kg calorific value. It is transported to a coal-water slurry boiler for...

Embodiment 2

[0018] Example 2: A city with a calorific value of 26.72MJ / kg, volatile content of 34.08%, fixed carbon of 53.93%, ash content of 11.14%, and water content of 78.13%, volatile content of 39.43%, fixed carbon of 11.18%, and ash content of 49.36% sludge.

[0019] Mix 10 parts of municipal sludge and 60 parts of coal by ball milling, add 0.75 parts of polycarboxylate-based dispersant and 29.3 parts of water during the ball milling process to obtain a particle size greater than 300 microns with a content of 0.09% and a content less than 75 microns It is 81.67% of the crude sludge coal water slurry; after the slurry is produced, it is allowed to stand for 15 minutes, and 0.6% to 0.7% of the total weight of the crude sludge coal water slurry is added to obtain a concentration of 60.57% and an ash content of 7.49%. The finished product coal water slurry with a sulfur content of 0.43%, a volatile content of 37.32% and a calorific value of 17.02MJ / kg. It is transported to a coal-water slur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com