Wet material boiler combustion treatment system with two drying devices

A boiler combustion and treatment system technology, applied in the direction of drying, drying machine, combustion method, etc., can solve the problems of surrounding air and soil corrosion, damage to the ecological environment, insufficient combustion, etc., to protect the health of the body and avoid occupying cultivated land , the effect of saving processing fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

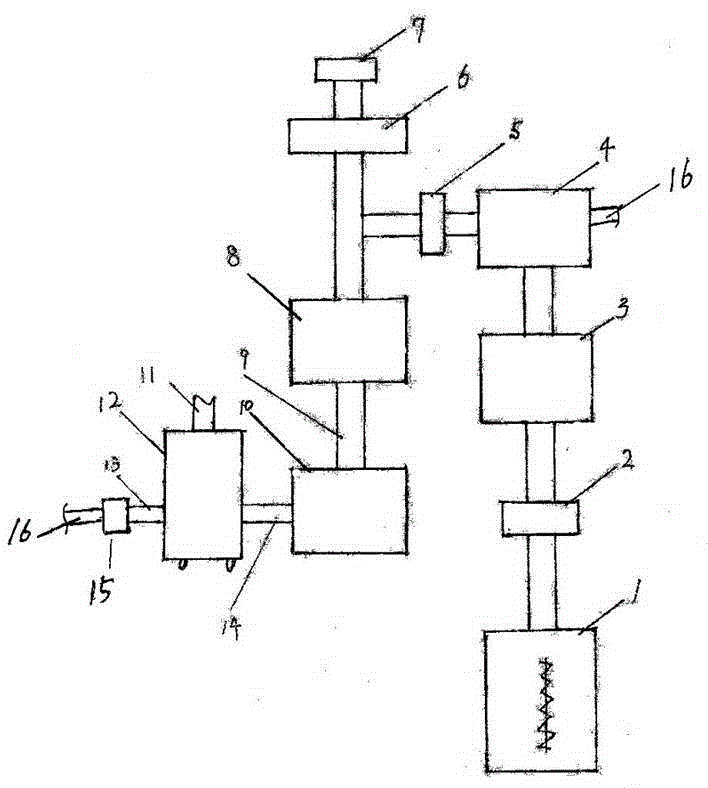

[0014] The designed boiler combustion treatment system for leaching medicine dregs or food dregs, see the accompanying drawings: the system includes two sets of drying equipment and a boiler, the two sets of drying equipment are composed of primary drying equipment and secondary drying equipment, of which The primary drying equipment is composed of a storage bin 1 equipped with an auger conveyor belt, a homogenizer 2, a squeezer 3, a rotary drum dryer 4 and a conversion auger 5 connected in sequence through pipelines: the secondary The drying equipment is formed by connecting the air blower 7, the heat exchanger 6, the airflow dryer 8 and the dry material bin 10 sequentially through pipelines, wherein the connecting pipeline between the airflow dryer 8 and the dry material bin 10 is a mixing conveying pipe; A boiler 12 for burning garbage is arranged beside the dry silo 10, and the feed port of the boiler is connected with the discharge port of the dry silo 10 through an auger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com