Efficient paint spraying circulation water treatment agent as well as preparation method and use method thereof

A circulating water and treatment agent technology, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of difficult separation of paint slag and circulating water, and achieve flocculation and floating Good effect, reduce cost, improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

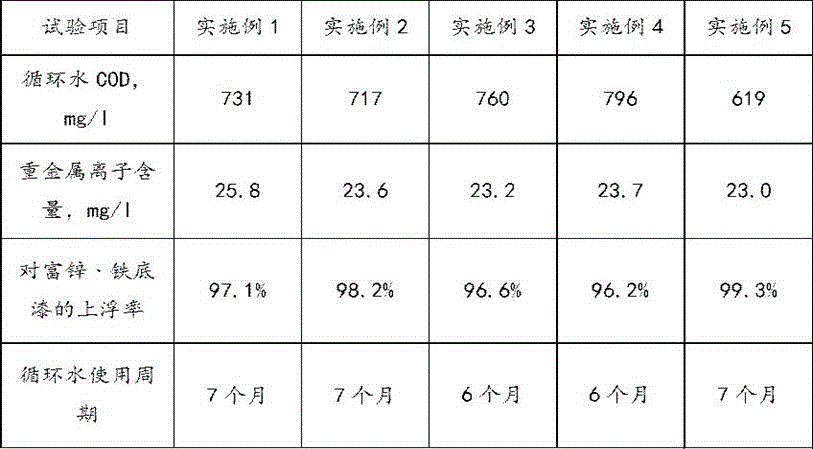

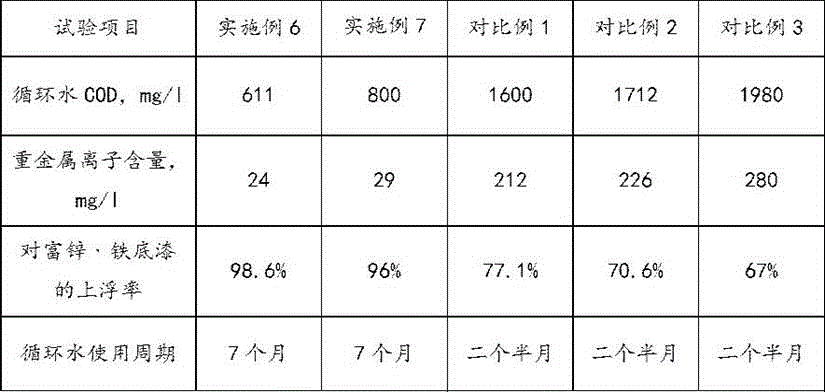

Examples

Embodiment 1

[0031] The high-efficiency spray paint circulating water treatment agent is composed of four independent components: agent A, agent B, agent C and agent D. Agent A is composed of compound X and water in a weight ratio of 1:5, and agent B is composed of weight average Cationic polyacrylamide with a molecular weight of 19 million is composed of water at a weight ratio of 1:100. Agent C is a mixture of compound Y and compound Z at a weight ratio of 1:1;

[0032] The production process of composition X is as follows: add 300g of polyacrylic acid into a 500ml beaker, heat it to 90℃ in a water bath, slowly add 30.8g of ammonia water into it, stir while adding to make it fully react, react for 10 minutes and then cool to 20℃ After aging for 1 hour, compound X is obtained;

[0033] The production process of compound Y is as follows: add 200g of polyaluminum chloride into the ultrafine pulverizer, add 16g of disodium ethylenediaminetetraacetic acid into it, turn on the pulverizer for 3 minu...

Embodiment 2

[0037] The high-efficiency spray paint circulating water treatment agent is composed of four independent components: agent A, agent B, agent C and agent D. Agent A is composed of compound X and water in a weight ratio of 1:5, and agent B is composed of weight average Cationic polyacrylamide with a molecular weight of 20 million is composed of water at a weight ratio of 1:100. Agent C is a mixture of compound Y and compound Z at a weight ratio of 1:1;

[0038] The production process of compound X is: add 320g of polyacrylic acid in a 500ml beaker, heat to 90-100°C in a water bath, slowly add 31g of ammonia water to it, stir while adding to make it fully react, react for 15 minutes and then cool to 25 After aging for 1.5 hours at ℃, compound X is obtained;

[0039] The production process of compound Y is: add 220g of polyaluminum chloride into the superfine grinder, add 17g of disodium ethylenediaminetetraacetic acid into it, turn on the grinder for 3 minutes, and smash to 200-300 me...

Embodiment 3

[0043] The high-efficiency spray paint circulating water treatment agent is composed of four independent components: agent A, agent B, agent C and agent D. Agent A is composed of compound X and water in a weight ratio of 1:5, and agent B is composed of weight average Non-ionic polyacrylamide with a molecular weight of 20 million is composed of water in a weight ratio of 1:100, and the C agent is a mixture of compound Y and compound Z in a weight ratio of 1:1;

[0044] The production process of composition X is: add 330g of polyacrylic acid into a 500ml beaker, heat to 95℃ in a water bath, slowly add 32g of ammonia water into it, stir while adding to make it fully react, and cool to 25℃ after reacting for 15 minutes. For 1.5 hours, compound X is obtained;

[0045] The production process of compound Y is: add 240g of polyaluminum chloride into the ultrafine pulverizer, add 17g of disodium ethylenediaminetetraacetic acid into it, turn on the pulverizer for 3 minutes, and smash to 200-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com