Method for preparing plum fruit wine and recycling fermentation waste residue

A technology for fermenting waste residue and fruit wine, applied in the field of food processing, can solve the problems of waste of organic resources, inability to make full use of it, pollute the environment, etc., and achieve the effects of low risk, recycling of waste, and high amino acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

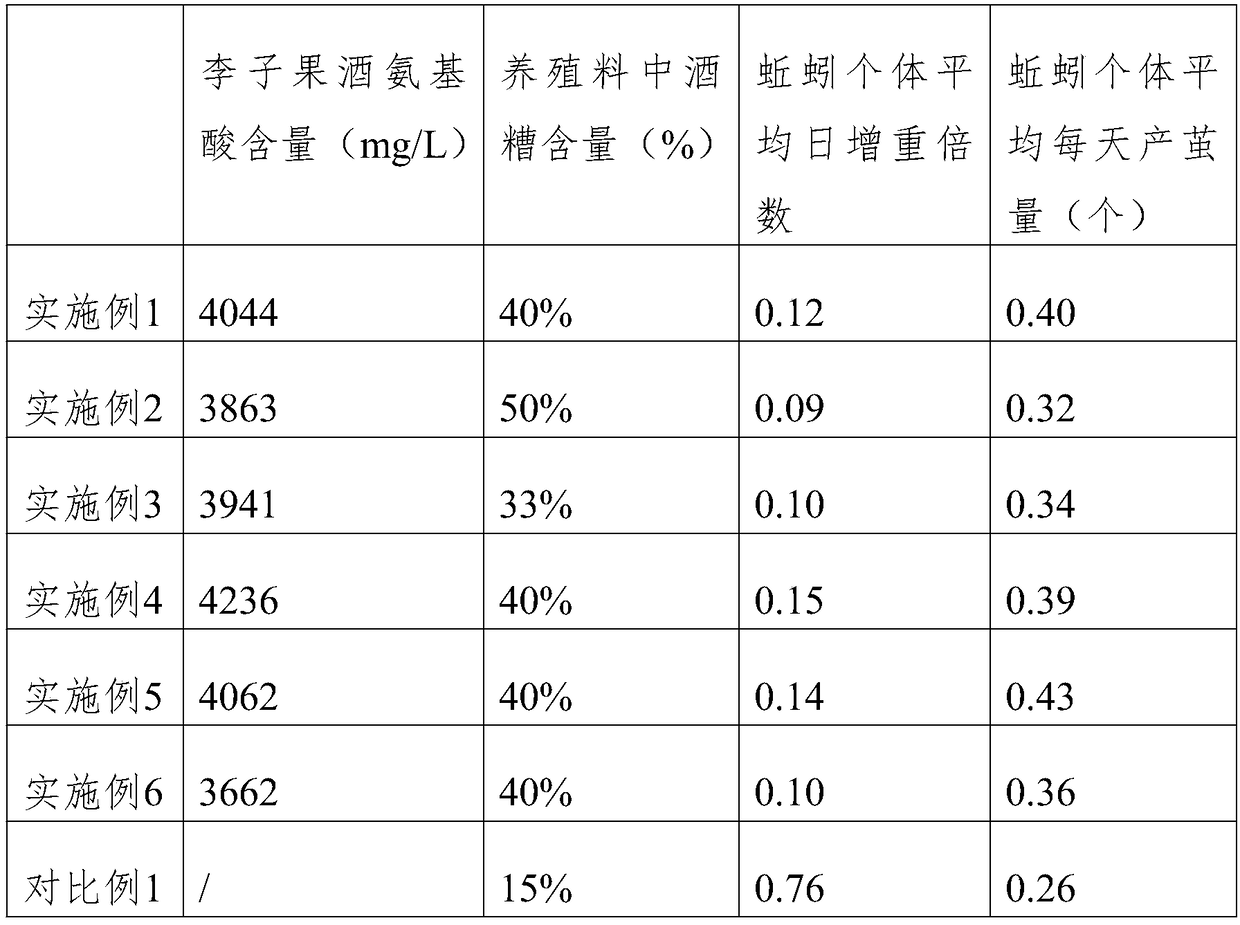

Examples

Embodiment 1

[0041] (1) Raw material sorting: choose 100kg of plum fruit with good maturity, full flesh, good color, no mechanical damage, no rot and deterioration, and the plum variety is blood red plum;

[0042] (2) Cleaning and sterilization: Wash the plums twice with salt water, remove the fruit stem, rinse with water twice, and then use K 2 S 2 o 5 water solution to wash the plums and then dry them, so K 2 S 2 o 5 The aqueous solution is to add 7.5 grams of K to 50L of water 2 S 2 o 5 get;

[0043] (3) Crushing and juicing: crushing the cleaned plums, removing the core and squeezing with a juicer to obtain the original puree and squeezed juice;

[0044] (4) Enzymolysis: Add pectinase and cellulase to the obtained raw pulp squeezed juice for enzymolysis, the amount of enzyme added is 67.5mg / L, the enzymolysis time is 1.25 hours, and the enzymolysis temperature is 24°C. The ratio of pectinase and cellulase is the mass ratio of pectinase: cellulase=2:0.75;

[0045] (5) Disinfec...

Embodiment 2

[0056] (1) Raw material sorting: choose 100kg of plum fruit with good maturity, full flesh, good color, no mechanical damage, no rot and deterioration, and the plum variety is blood red plum;

[0057] (2) Cleaning and sterilization: Wash the plums twice with salt water, remove the stems, rinse with clean water once, and then rinse with K 2 S 2 o 5 water solution to wash the plums and then dry them, so K 2 S 2 o 5 The aqueous solution is to add 10 grams of K to 50L of water 2 S 2 o 5 get;

[0058] (3) Crushing and juicing: crushing the cleaned plums, removing the core and squeezing with a juicer to obtain the original puree and squeezed juice;

[0059] (4) Enzymolysis: Add pectinase and cellulase to the obtained raw pulp squeezed juice for enzymolysis, the amount of enzyme added is 55mg / L, the enzymolysis time is 2 hours, and the enzymolysis temperature is 30°C. The ratio of pectinase and cellulase is mass ratio pectinase: cellulase=2.5:0.5;

[0060] (5) Disinfection ...

Embodiment 3

[0071] (1) Raw material sorting: choose 100kg of plum fruit with good maturity, full flesh, good color, no mechanical damage, no rot and deterioration, and the plum variety is blood red plum;

[0072] (2) Cleaning and sterilization: wash the plums twice first, then wash them with salt water, remove the stems, rinse them with water three times, and then wash them with K 2 S 2 o 5 water solution to wash the plums and then dry them, so K 2 S 2 o 5 The aqueous solution is to add 10 grams of K to 50L of water 2 S 2 o 5 get;

[0073] (3) Crushing and juicing: crushing the cleaned plums, removing the core and squeezing with a juicer to obtain the original puree and squeezed juice;

[0074] (4) Enzymolysis: Add pectinase and cellulase to the obtained raw pulp squeezed juice for enzymolysis, the amount of enzyme added is 80mg / L, the enzymolysis time is 0.5 hours, and the enzymolysis temperature is 18°C. The ratio of pectinase and cellulase is the mass ratio pectinase: cellulas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com