Sludge dewatering method for waste paper deinking technology

A technology for sludge dehydration and waste paper deinking, which is applied in waste paper processing, papermaking, paper recycling, etc., can solve the problems of low sludge concentration in gravity bed, loss of suspended flow, and increased pollution load of sewage treatment plants, and achieves improved Treatment effect, reduction of treatment costs, considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The basic process of this embodiment is carried out in the following steps:

[0017] Thin sludge, sludge storage tank, gravity bed, screw conveyor, screw press, sludge discharge.

[0018] Among them: add concentrated sulfuric acid in the sludge storage tank, add cationic PAM in the gravity bed and drain the filtered water, and filter the discharged water in the process of the screw press.

[0019] The principle analysis of the method

[0020] The above excellent effects have been achieved through simple changes. This is by no means explained by ordinary sludge conditioning and pH adjustment principles, but is achieved through complex chemical reactions. Facts have proved that after the above changes, the pH value of the sludge, The electrical charge did not change much, but the chemical composition of the sludge changed qualitatively.

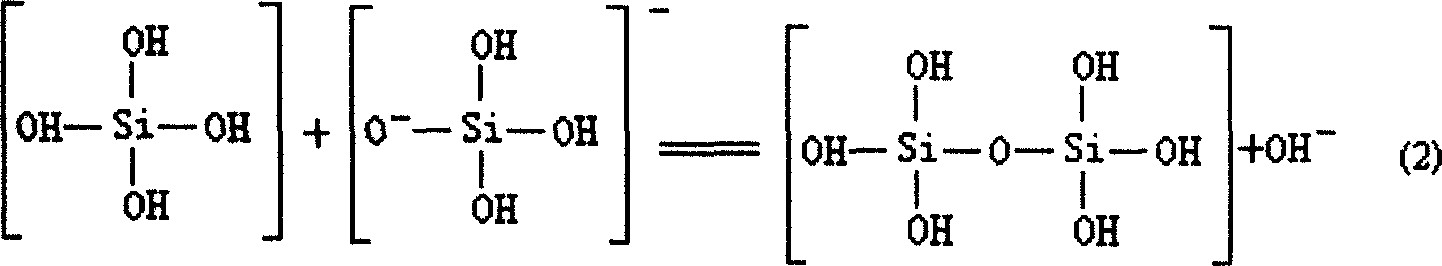

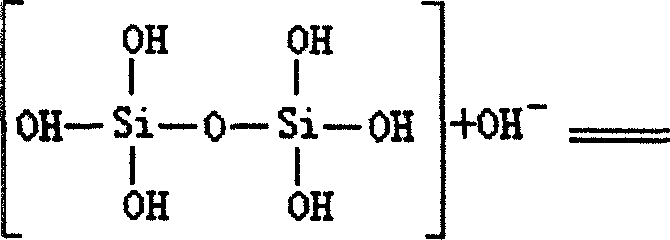

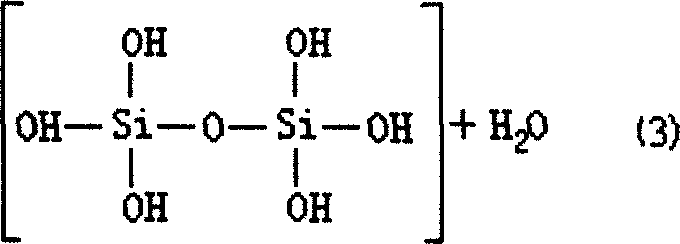

[0021] (1) Effect on sodium silicate

[0022] In the flocculation reaction of sludge adding cationic PAM, sodium silicate has a stro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com