City sewage sludge reclamation processing and utilization method

A municipal sludge recycling technology, applied in the field of recycling municipal sludge, can solve the problems of increased pulping cost, increased process links, unsuitable for large-scale and commercial promotion and application, and achieves significant environmental benefits, The effect of saving coal and water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

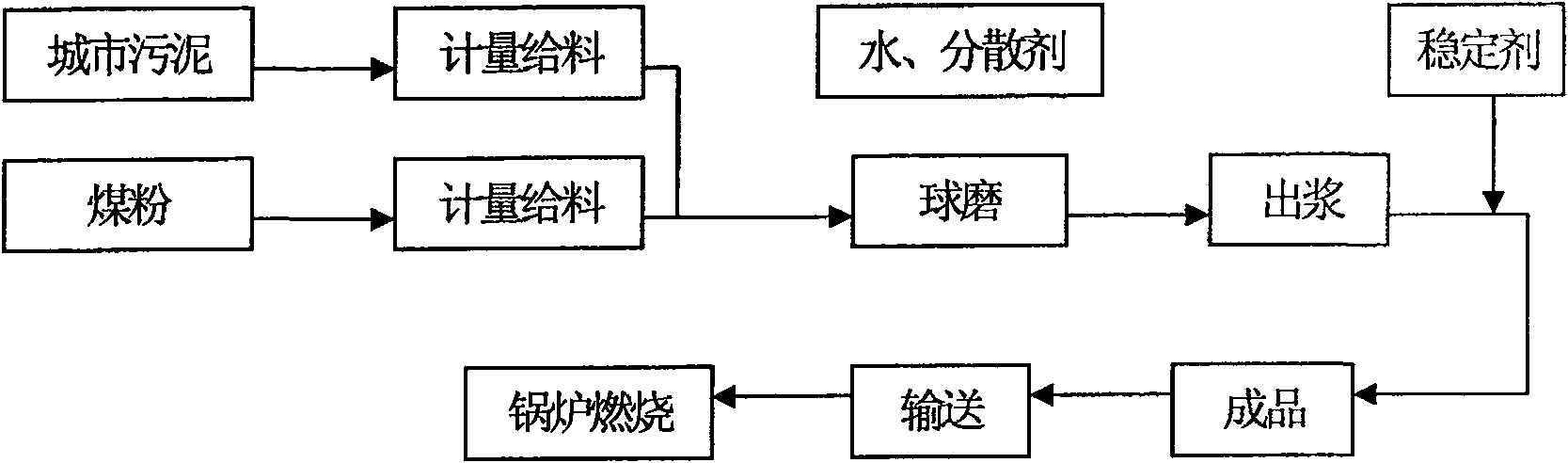

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Coal with a calorific value of 26.82MJ / kg, volatile matter of 33.61%, fixed carbon of 54.19%, and ash content of 10.49% and a city with a moisture content of 78.50%, volatile matter of 37.25%, fixed carbon content of 5.44%, and ash content of 57.31% sludge.

[0017] Mix 5 parts of urban sludge and 62 parts of coal for ball milling, add 0.5 parts of lignosulfonate dispersant and 32.5 parts of water during the ball milling process to obtain 0.07% of the particle size greater than 300 microns and less than 75 microns It is 81.86% of the crude coal water slurry of sludge; after the slurry is discharged, it is left to stand for 10 minutes, and a carboxymethyl cellulose stabilizer of 0.6% to 0.7% of the total weight of the crude coal water slurry of the sludge is added to obtain a concentration of 61.95%, and the ash content 7.16%, sulfur 0.40%, volatile matter 37.02%, calorific value of 17.44MJ / kg finished coal water slurry. It is transported to the coal-water sl...

Embodiment 2

[0018] Example 2: Coal with a calorific value of 26.72MJ / kg, 34.08% volatile matter, 53.93% fixed carbon, and 11.14% ash content and a city with a moisture content of 78.13%, 39.43% volatile matter, 11.18% fixed carbon, and 49.36% ash content sludge.

[0019] Mix 10 parts of municipal sludge and 60 parts of coal for ball milling, add 0.75 parts of polycarboxylate dispersant and 29.3 parts of water during the ball milling process to obtain 0.09% of the particle size greater than 300 microns and less than 75 microns It is 81.67% of the crude coal water slurry; after the slurry is discharged, it is allowed to stand for 15 minutes, and 0.6% to 0.7% of the total weight of the crude coal water slurry is added to obtain a concentration of 60.57%, and the ash content is 7.49%. The finished coal water slurry has a sulfur content of 0.43%, a volatile content of 37.32%, and a calorific value of 17.02MJ / kg. It is transported to the coal-water slurry boiler for combustion, and its burnout...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com