Novel dyeing process for blended knitting yarn

A technology of knitting yarn and new process, applied in the field of new dyeing process of blended knitting yarn, can solve the problems of poor levelness of dyestuff, complicated dyeing process and high production cost, reduce the cost of auxiliaries, stabilize the dyeing process, and save water treatment. effect of fee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions of the present invention will be further described below in conjunction with the embodiments.

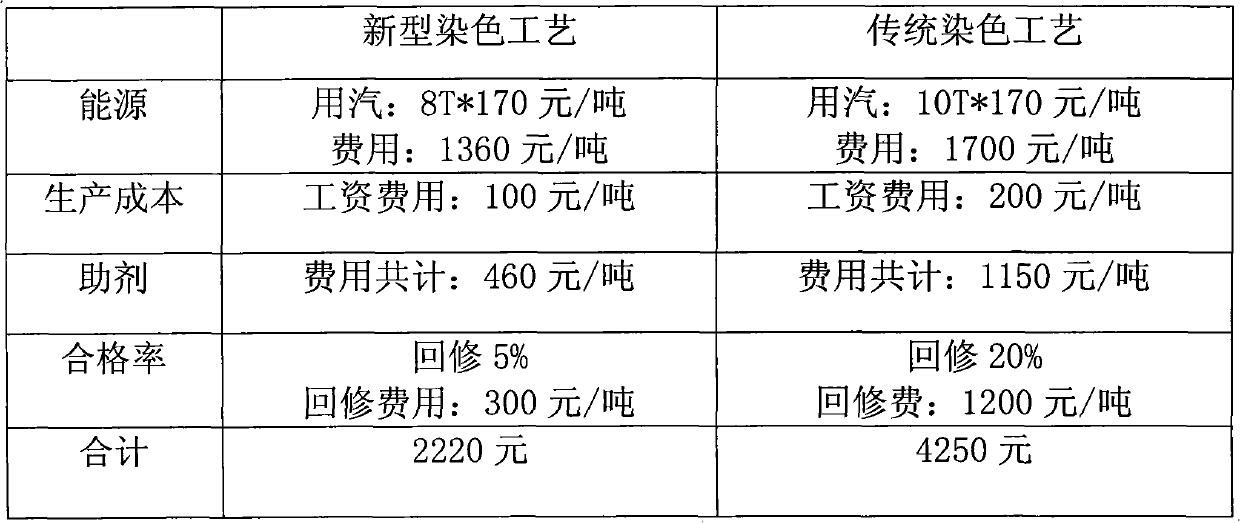

[0013] 1. Traditional dyeing process: Take blended 72S / 2 as an example.

[0014] 1. The process flow is as follows:

[0015] (6) At room temperature 20°C, add penetrating agent, acetic acid, Albergo B (leveling agent) and dye (washed with 80°C water), and thread for 60 minutes.

[0016] (7) Turn on the steam to raise the temperature, and raise the temperature to 50° C. at a rate of 1° C. every 3 minutes, and keep warm.

[0017] (8) Add dispersants and cationic dyes, and thread for 30 minutes.

[0018] (9) Raise the temperature to 100° C. at a rate of 1° C. per minute, and keep warm.

[0019] (10) Fix the color for 60 minutes, cool down, and go out.

[0020] In this dyeing process, the dyeing time is 390 minutes, and the fixation time is 60 minutes, totaling 450 minutes. 80% qualified rate of one-time dyeing machine.

[0021] 2. Defects of traditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com