Method for comprehensively treating grating garbage and activated sludge in sewage plant

A technology of activated sludge and comprehensive treatment, applied in dehydration/drying/thickened sludge treatment, sewage/sludge fertilizer, application, etc., to achieve the effects of reducing floor space, saving operating costs, and saving equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

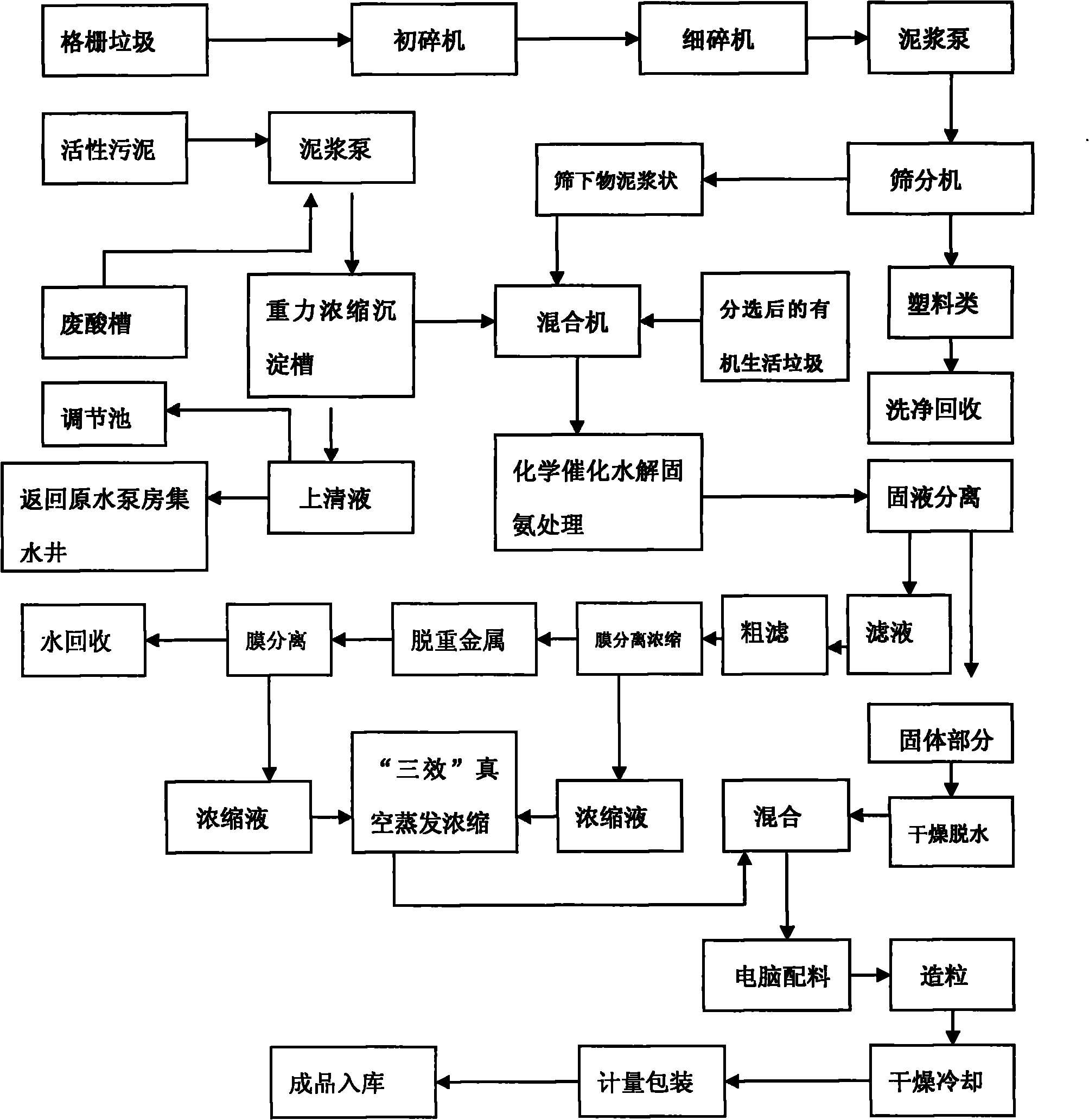

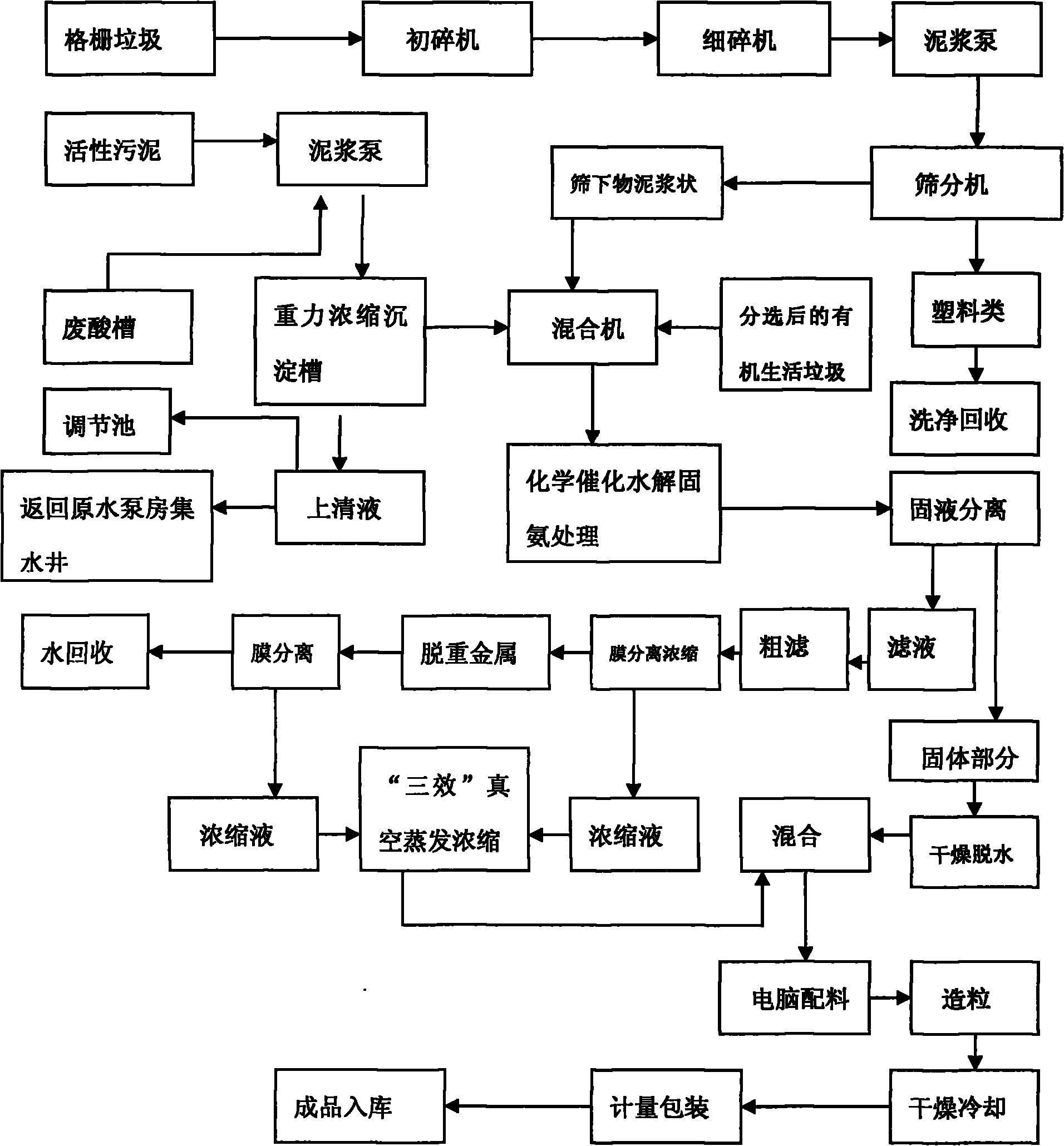

[0019] Such as figure 1 As shown in the figure, a comprehensive treatment method for screen waste and activated sludge in a sewage plant is mainly to mix the pretreated screen waste with the activated sludge concentrated by one-step method, and then chemically catalyze it together with the sorted organic domestic waste. After hydrolysis and solid ammonia treatment, the organic energy fertilizer is prepared by using the prior art. After the grid waste is intercepted by the grid, it is pre-treated. Firstly, the large-sized waste is crushed into small-sized 1-5mm waste by the primary crusher, and then enters the high-speed rotary cutter fine crusher for further primary crushing. The final garbage is finely crushed into a slurry of less than 1mm, and then s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com