Hazardous waste harmless incineration system with low energy consumption

A waste and harmless technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of high treatment costs and high energy consumption, improve the utilization efficiency of thermal energy, reduce treatment costs, and be environmentally friendly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

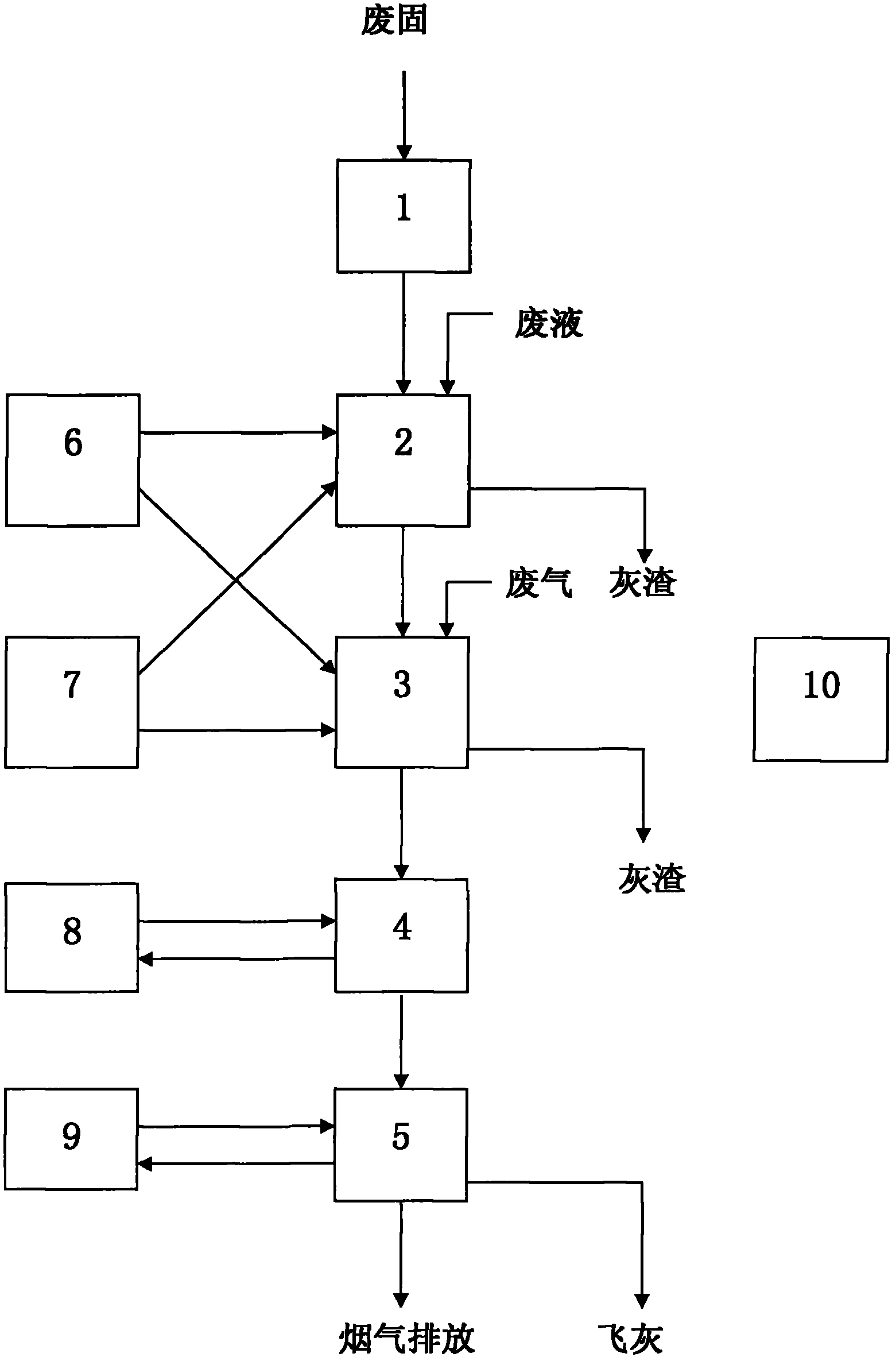

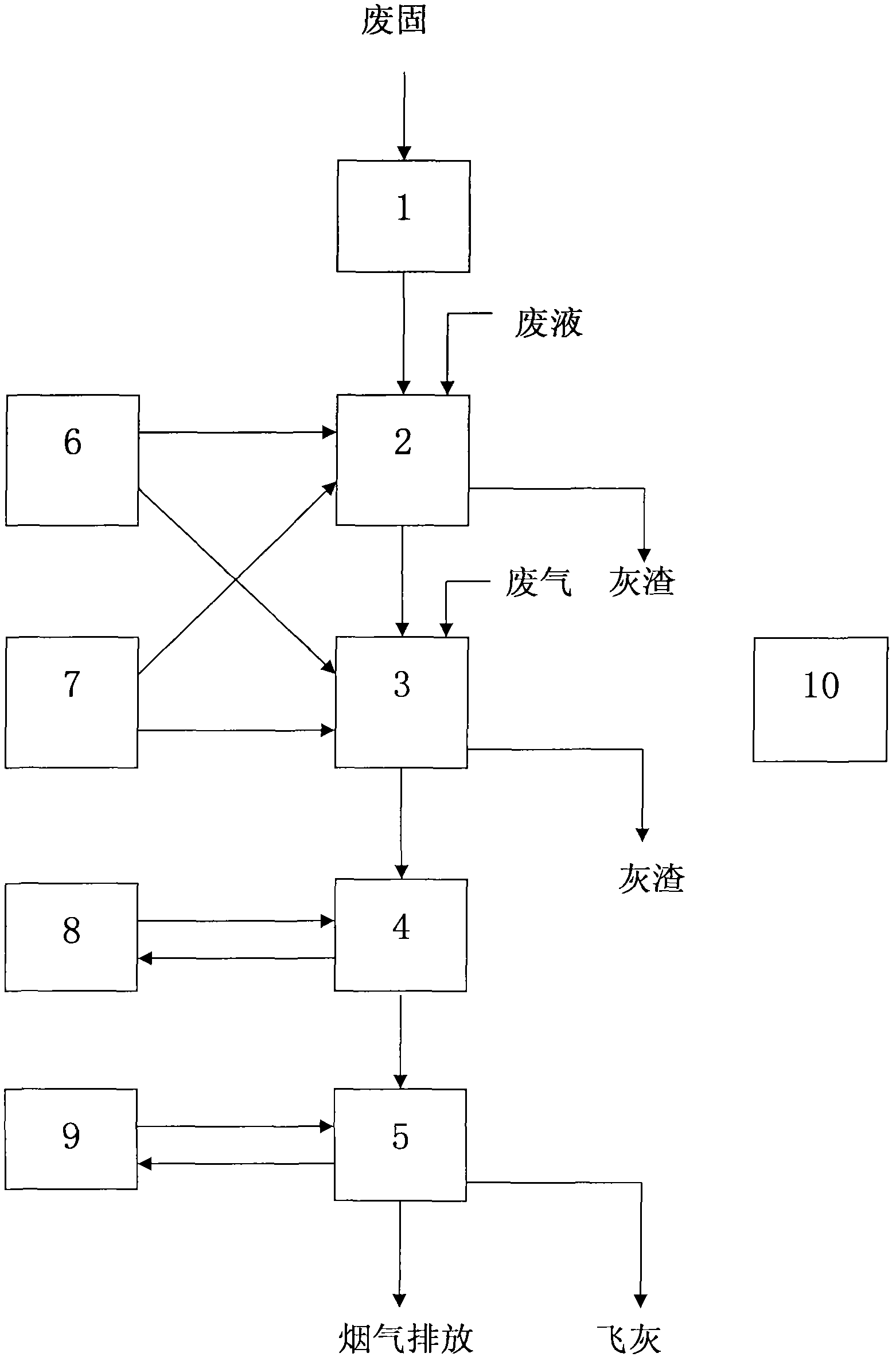

[0027] see figure 1 , low-energy hazardous waste harmless incineration system, including: waste solid feeding equipment 1, waste solid and waste liquid gasification incineration unit 2, waste gas purification and incineration unit 3, waste heat recovery unit 4 and flue gas treatment unit 5 and other main bodies Equipment, as well as auxiliary equipment such as fuel supply equipment 6, combustion air supply equipment 7, heat exchange medium supply equipment 8, harmful gas adsorbent supply equipment 9, automatic control and safety protection equipment 10, etc.

[0028] Waste solid feeding equipment 1 is composed of a grab bucket, a hopper, an airtight conveyor belt, and a pusher.

[0029] Process flow: Harmful solid waste is sent from the storage yard to the hopper by the operator using a grab bucket, and then sent to the pusher through a closed conveyor belt to continuously feed the waste solid and waste liquid gasification incineration unit 2.

[0030] Waste solid and waste l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com