Production method of paper mill sludge landscape ornamental material

A technology of papermaking sludge and production methods, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of high energy consumption and excessive product quality, and achieve low energy consumption and light product quality , The effect of solving the problem of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

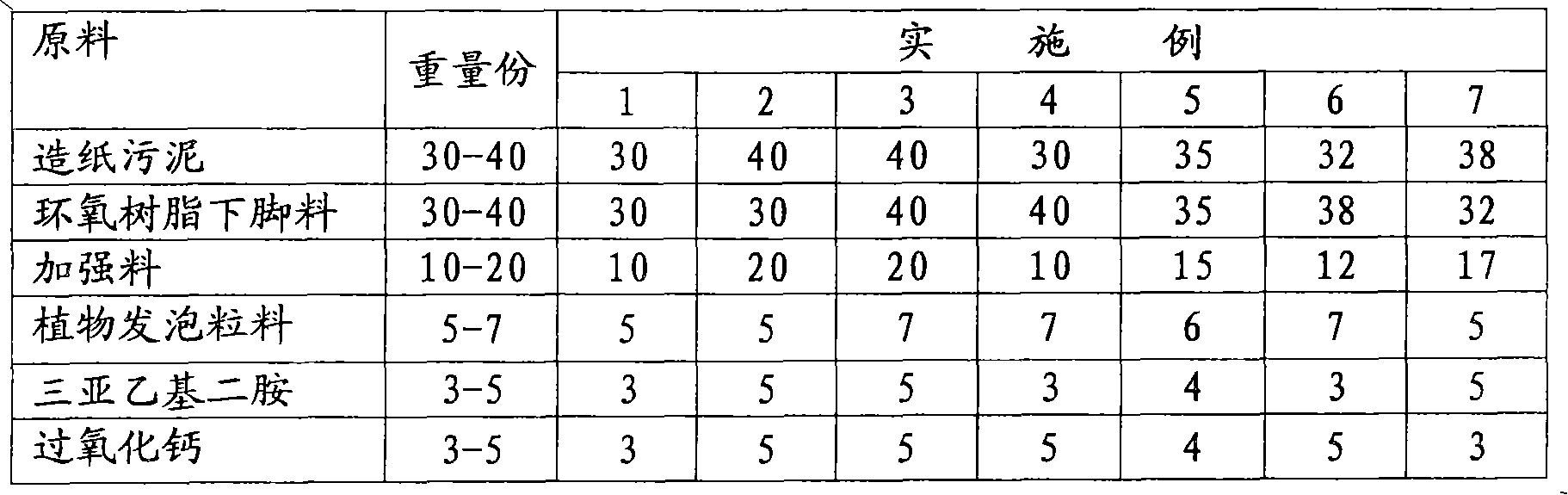

[0016] Embodiment 1 (with reference to the corresponding raw materials and parts by weight of embodiment 1 in the table): each raw material is prepared according to the requirements of step (1) to prepare the material, with 30 parts of papermaking sludge, 30 parts of epoxy resin waste, 10 parts of wood Silk and / or bamboo silk, 5 parts of plant foaming pellets, 3 parts of triethylenediamine and 3 parts of calcium peroxide are mixed, fully kneaded and mixed in a kneader, and poured into a multi-layer press template for Hot pressing, pressure 1MPa, temperature 120°C, pressing for 15 minutes, unloading and stacking, curing for 24 hours, and then polishing and sanding the surface of the board.

Embodiment 2

[0017] Embodiment 2 also refers to the corresponding raw materials and parts by weight of Embodiment 2 in the table. The method is basically the same as that of Embodiment 1, but the reinforcing material added is 20 parts of plastic braided short material, the pressure of hot pressing is 0.6 MPa, the temperature is 100 ° C, and the time 20min.

Embodiment 3

[0018] The basic method of Example 3 is the same as before, but 20 parts of brown silk are added, the hot pressing temperature is 110° C., the pressure is 0.8 MPa, and the time is 10 minutes.

[0019] For the remaining examples 4-7, refer to the raw materials and weight ratio values in the table, and make boards according to the basic method of Examples 1-3. After the boards are polished and sanded, then use unsaturated resin to paint the board surface or transfer printing or Make surface beautification by punching out hole patterns and other methods. This board is especially suitable as a flower bed enclosure in the landscape area. The length and width of the board are determined by mold making according to the design requirements, and the thickness is 1-2cm.

[0020] Among the seven examples, examples 1, 3, and 5 are preferred.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com