Household pure straw biogas fermentation process

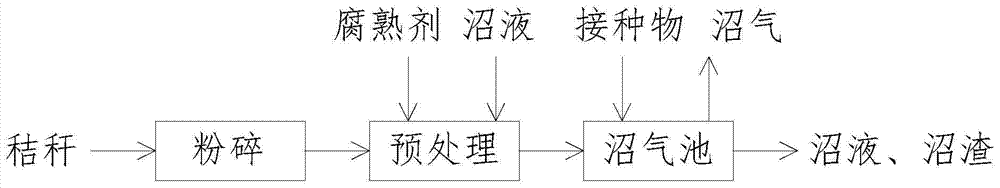

A biogas fermentation and straw technology is applied in the field of household pure straw biogas fermentation technology, which can solve the problems of unstable reaction process, inability to continue to function, increase gas production, etc. The effect of reducing material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] The household pure straw biogas fermentation process of this embodiment consists of the following steps:

[0040] The first step, prepare materials:

[0041] S1. 7-9% (preferably 8%) of the total weight of the preset feed liquid of the household biogas digester is used as the total weight of the straw, and the straw is taken according to the total weight of the straw for subsequent use;

[0042] S2. 0.1-0.3% (preferably 0.2%) of the total weight of the straw is used as the weight of the decomposing agent, and the straw decomposing agent is taken according to the weight of the decomposing agent for subsequent use;

[0043] S3. 120-150% of the total weight of the straw is used as the weight of the pretreatment liquid, and the biogas slurry of a biogas digester in normal operation is taken according to the weight of the pretreatment liquid as the pretreatment liquid and set aside;

[0044] S4. 40-50% of the total weight of the preset feed solution of the household biogas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com