Low-carbon papermaking method

A technology of black liquor and sewage, applied in papermaking, textile and papermaking, washing/replacing pulp treatment fluid, etc., can solve problems such as a drop in the bucket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

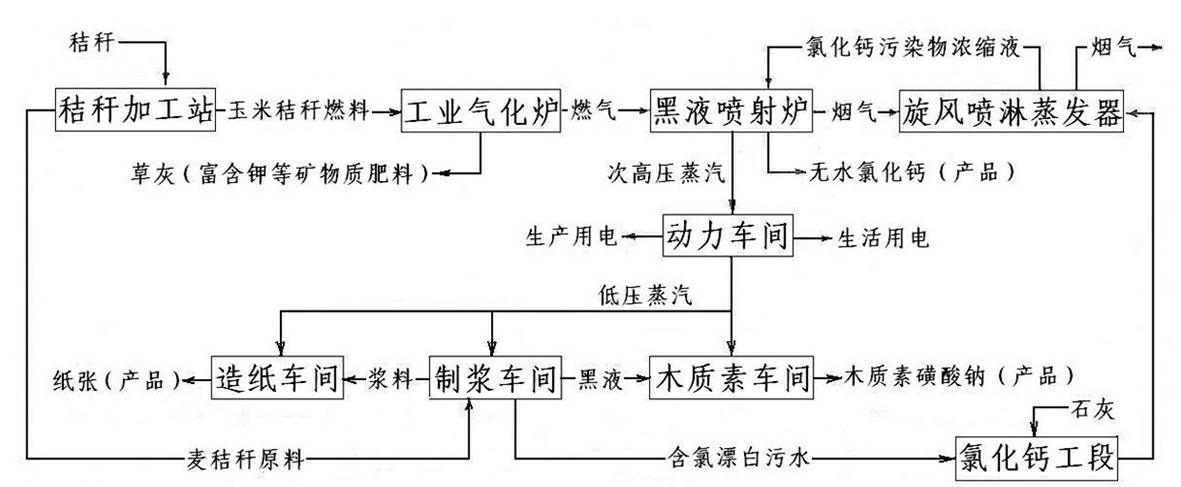

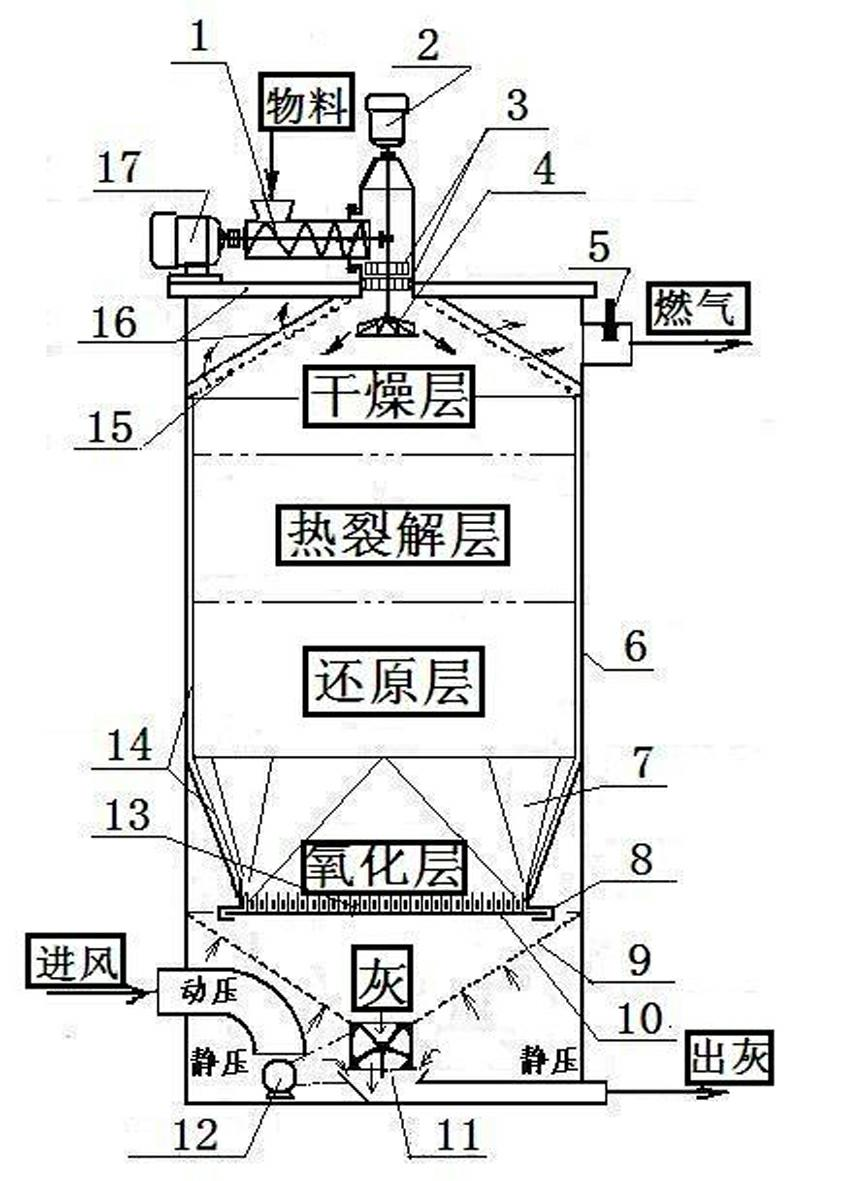

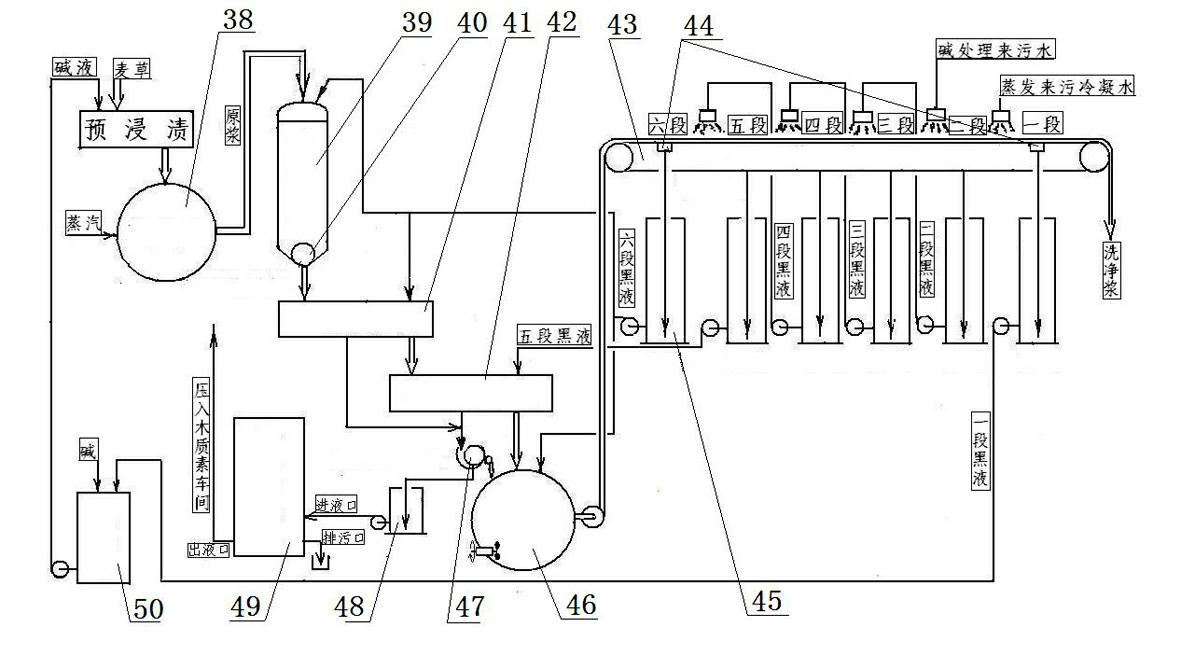

[0032] Example: such as figure 1 Shown is the low-carbon papermaking flow chart of this embodiment. This embodiment is a low-carbon papermaking method, which specifically involves the comprehensive utilization of straw for pulping, papermaking, and the use of pulping pollutants to produce secondary products to achieve zero emissions in clean production. Utilize renewable resources of wheat straw and corn straw as raw materials and fuels for low-carbon papermaking respectively; low-carbon papermaking enterprises retain traditional pulping workshops, papermaking workshops and their traditional pulping and papermaking technology and equipment, and improve white water recycling, The cooking process of the pulping workshop, the extraction method of black liquor and the treatment of bleaching waste liquor; at the same time, a new energy and environmental technology department has been added, under the jurisdiction of: ① Straw processing station - complete raw materials (such as wheat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com