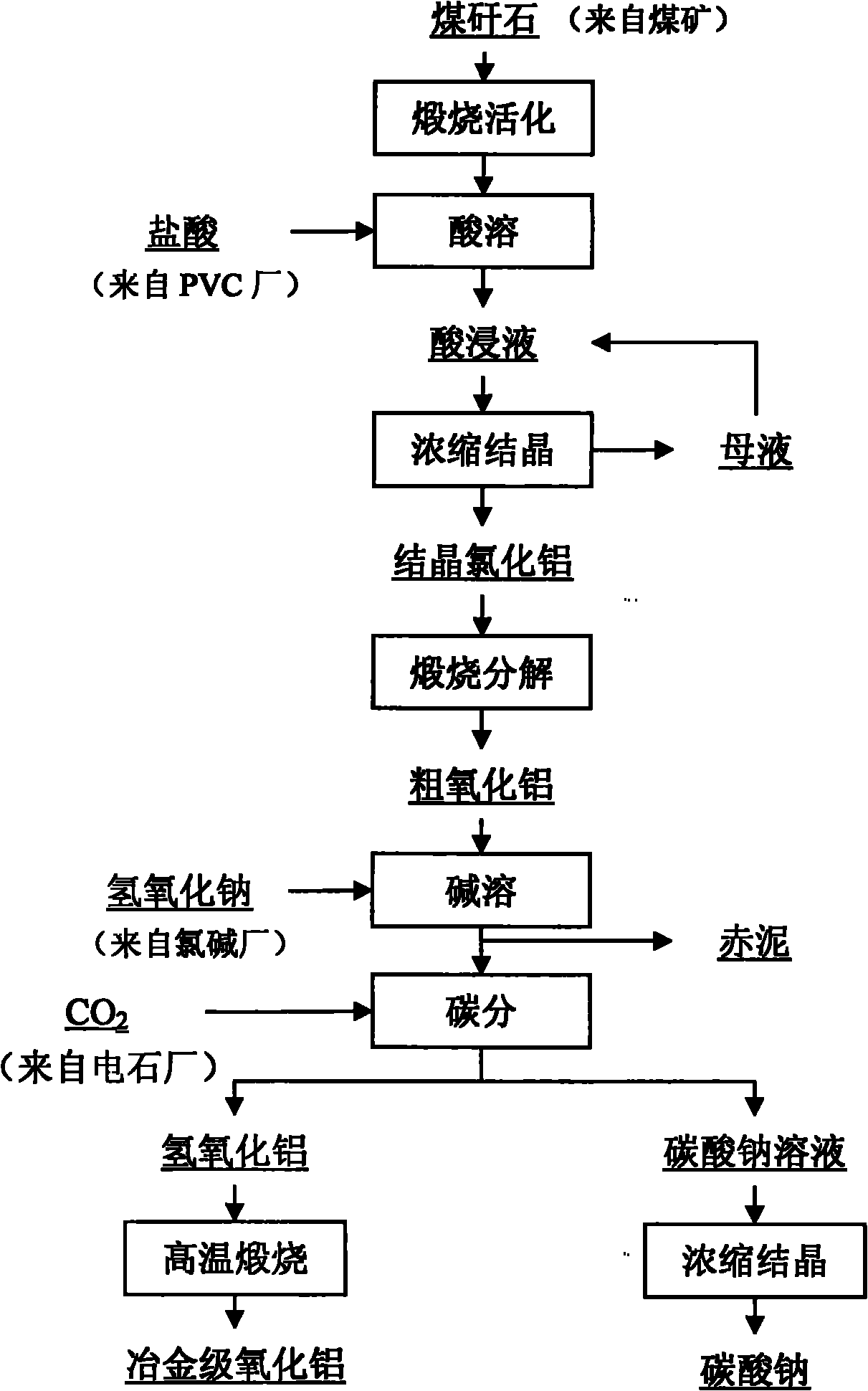

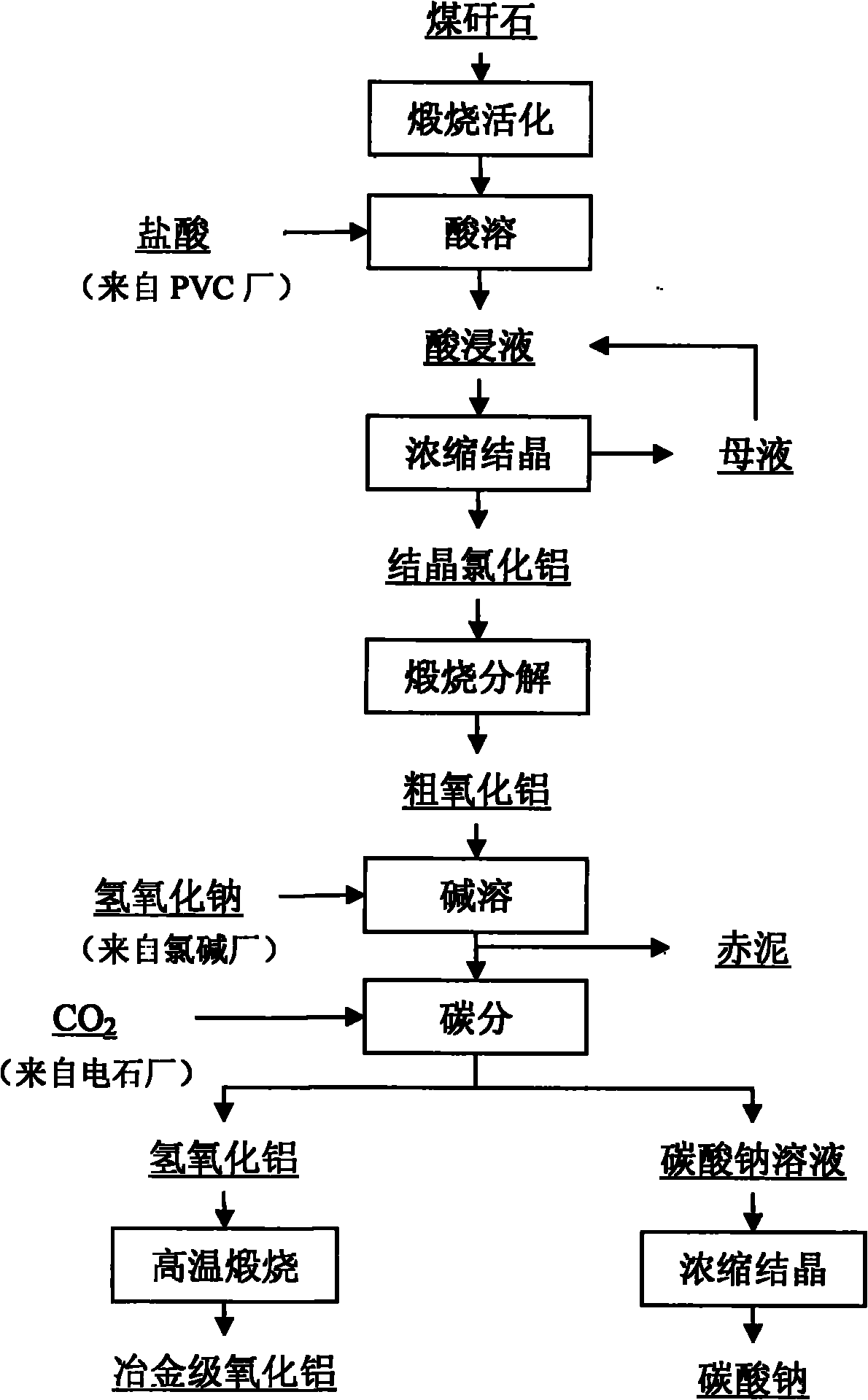

Method for co-producing aluminum oxide and sodium carbonate from coal gangue

A coal gangue and sodium carbonate technology, applied in the direction of alumina/hydroxide preparation, carbonate preparation, etc., can solve the problems of unguaranteed product purity, high raw material purity requirements, serious environmental pollution, etc., and achieve easy production process Effect of controlling and reducing industrial pollution and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]Take 100Kg of coal gangue discarded in the industrial park of Ordos City, crush it to 250 mesh, and calcinate it at 900° C. for 0.5 hour in a circulating fluidized bed roaster to obtain ash. After cooling, put it into an acid-resistant reaction kettle, and add hydrochloric acid, a by-product of the polyvinyl chloride (PVC) factory in Ordos Industrial Park, to carry out acid-dissolving reaction. , pressure 1.0MPa, and react for 2 hours. After the reaction product is filtered and washed by a basket filter press, the aluminum chloride acid immersion solution is obtained. Send the aluminum chloride acid immersion solution into the concentration tank, and concentrate it for 8 hours at a pressure of -0.04MPa and a temperature of 90°C. The concentrated liquid is placed in a buffer cooling tank, cooled naturally at room temperature, and filtered through a belt vacuum Machine filtration to obtain crystalline aluminum chloride. The crystalline aluminum chloride is placed in a ca...

Embodiment 2

[0031] a, get 100Kg of abandoned coal gangue in Ordos City Industrial Park, pulverize the coal gangue to below 200 mesh, and calcinate and activate it in a roaster at 700°C for 2.0 hours to obtain activated gangue ash;

[0032] B, place the ash slag after calcining and activation in the acid-resistant reaction kettle, add the by-product hydrochloric acid of polyvinyl chloride (PVC) factory in Ordos City Industrial Park to carry out acid-dissolution reaction, concentration is 31wt% hydrochloric acid, every kilogram of ash slag adds 1.8 liters of hydrochloric acid , the reaction temperature is 100°C, the reaction time is 1.0 hour, the pressure is 2.0MPa, and the pickling solution is prepared;

[0033] c. The pickling solution is subjected to solid-liquid separation and washing to obtain the aluminum chloride pickling solution

[0034] d. Send the aluminum chloride acid immersion solution into the concentration tank for negative pressure concentration. The concentration pressure ...

Embodiment 3

[0040] a, get 100Kg of abandoned coal gangue in Ordos City Industrial Park, pulverize the coal gangue to below 200 mesh, and calcinate and activate in 800° C. roasting furnace for 1.5 hours to obtain activated gangue ash;

[0041] B, place the ash slag after calcining activation in the acid-resistant reaction kettle, add the by-product hydrochloric acid of polyvinyl chloride (PVC) factory in Ordos City Industrial Park to carry out acid-dissolution reaction, concentration is 22wt% hydrochloric acid, every kilogram of ash slag adds 2.5 liters of hydrochloric acid , the reaction temperature is 200°C, the reaction time is 3.0 hours, the pressure is 1MPa, and the pickling solution is prepared;

[0042] c. The pickling solution is subjected to solid-liquid separation and washing to obtain the aluminum chloride pickling solution

[0043] d. Send the aluminum chloride acid immersion solution into the concentration tank for negative pressure concentration. The concentration pressure is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com