Patents

Literature

62results about How to "Reduce industrial pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Helix bevel gear active tooth threading machining process

ActiveCN101428387AWorkshop environment cleanReduce industrial pollutionThread cutting machinesSolid state diffusion coatingThermal insulationCarbon alloy

The invention relates to a processing technology for driving gear hard cutting threading of a spiral bevel gear in a main decelerator for processing an automobile, the processing technology is characterized in that heat treatment on Phi 10-Phi 100 mm low carbon alloy steel base materials-carburization quenching-tempering-heat insulation for 2 hours at the temperature of 170 to 180 DEG C-annealing at the thread part at the temperature of 600 to 900 DEG C and the surface hardness of 28 HRC-43 HRC-dry cutting of thread, the rotating speed of work pieces at 500 to 900 circles per minute, the cutting speed at the 50 to 80 meters per minute-detection for warehousing. The invention has the advantages that the processing precision is high, the efficiency is high, the cost is low, the technological process is reduced, by adopting the dry cutting process, the cutting oil is not required, and the invention is pollution-free.

Owner:ZHUZHOU GEAR CO LTD

Method for extracting lithium chloride from high lithium salt lake brine

The invention relates to the chemical engineering field of inorganic salt and discloses a method for extracting lithium chloride from high lithium salt lake brine. The method disclosed by the invention comprises: adding inorganic salt into salt lake brine to remove calcium and magnesium ions and boron ions; adding a chelating agent to remove trace calcium and magnesium ions; and carrying out spray-drying treatment to obtain lithium chloride solid grains. By adopting inorganic acid and alkali to remove impurities, the production cost is lowered and the industrial pollution is reduced; the lithium chloride product obtained by spray-drying treatment is uniform in grain size, less in agglomeration and high in purity.

Owner:韦海棉

Polymer modified binding material of sulphate aluminum cement base

The invention discloses a polymer modified binding material of sulphate aluminum cement base. The polymer modified binding material of sulphate aluminum cement base is prepared from, by weight, 750-850 parts of modified cement, 900-1350 parts of quartz sand, 100-120 parts of mineral admixture, 5-8 parts of modified polymer gelatine powder, 2-4 parts of retarder, 4.5-9 parts of water reducing agent, 0.05-0.1 part of defoaming agent; the allowance is water. Meanwhile, the invention further discloses a preparation method of the polymer modified binding material, which includes steps of weighting raw materials at ratio, adding water to stir, and preparing to be slurry, and others. The binding material prepared by the invention can improve the binding ability between interfaces by modifying a polymer; the binding material is high in binding strength and good in flowability; the novel polymer modified binding material with good economic benefit and social benefit has advantages of preventing flash setting and fully saving material and cost.

Owner:长荣新材料技术有限公司

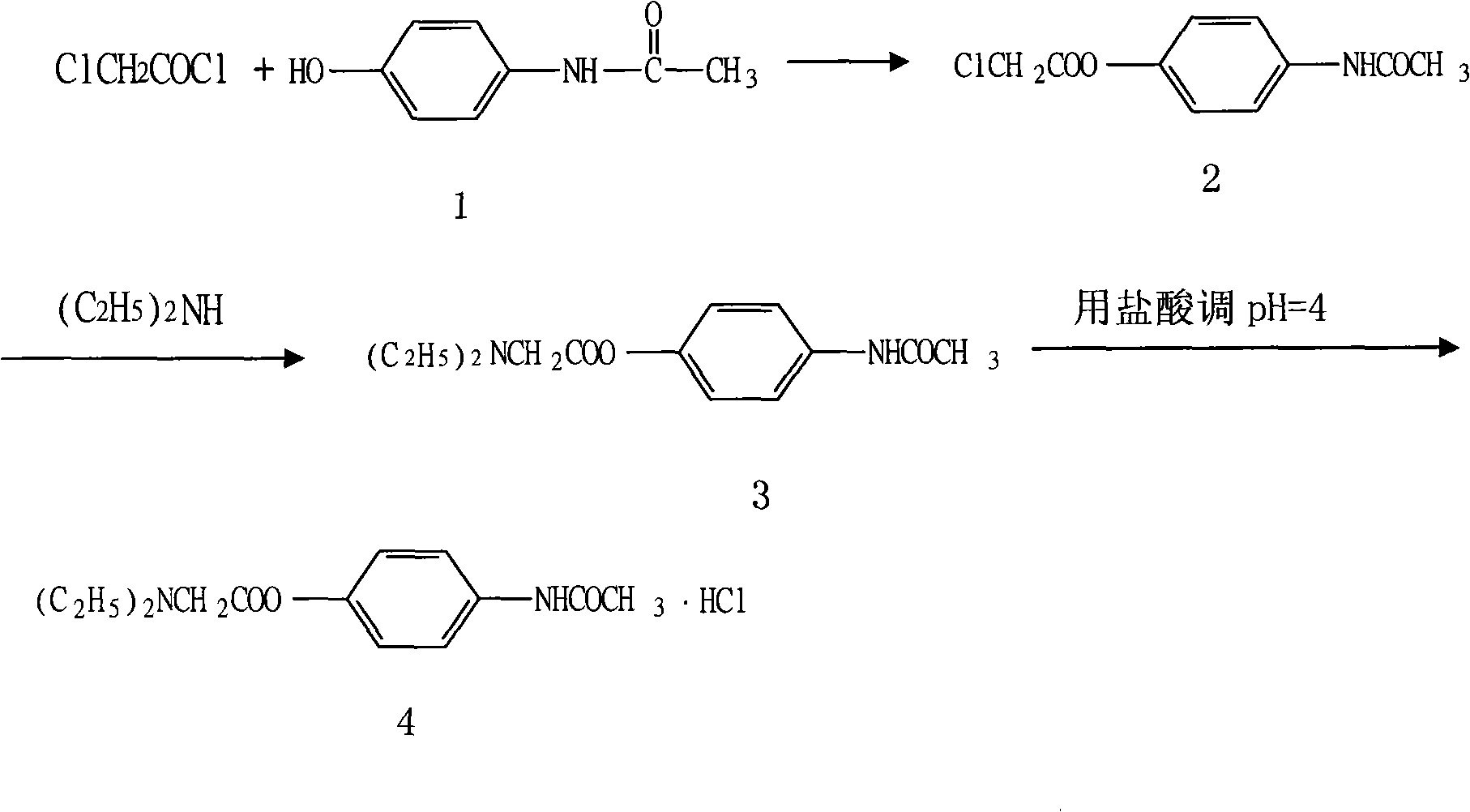

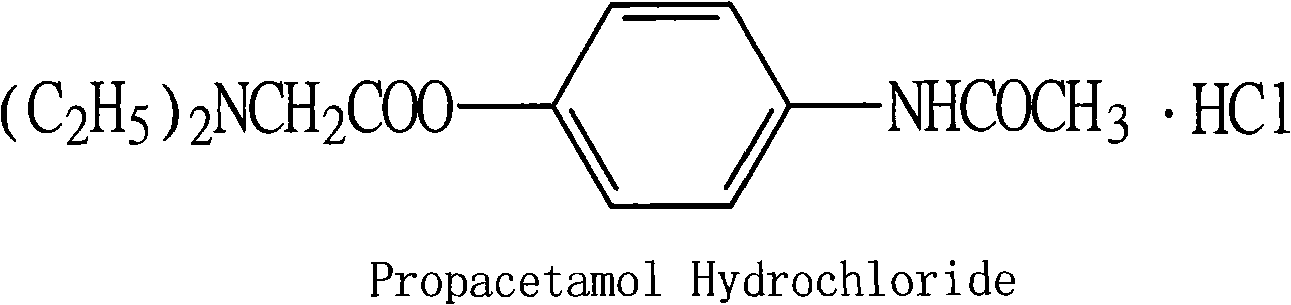

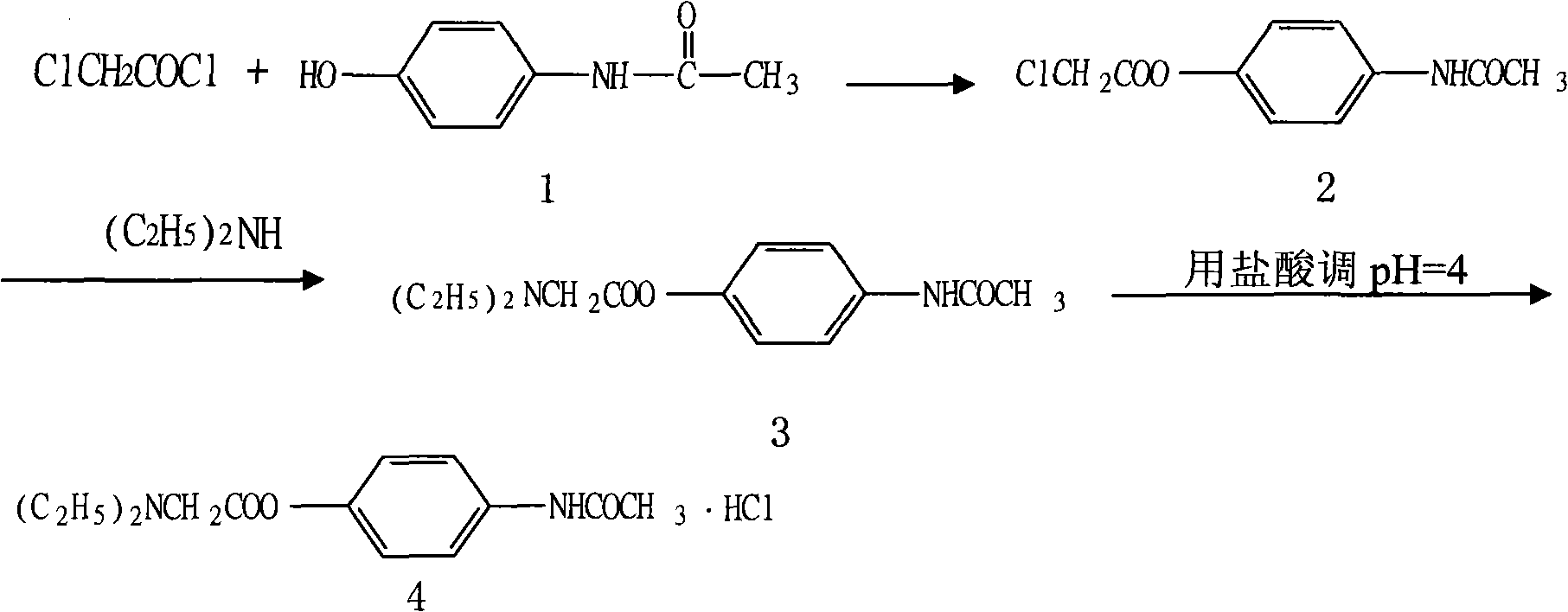

Preparation of propacetamol hydrochloride

InactiveCN101353314ASimplify purification operationsHigh yieldOrganic compound preparationCarboxylic acid amides preparationAcetic acidPropacetamol

The invention provides a preparation method of propacetamol hydrochloride. The preparation method is characterized in that chloracetyl chloride and paracetamol carry out an acetylization chloride reaction in a polar aprotic solvent to obtain chloroactic acid-4-acetylamino phenyl ester which is directly aminated with diethylamine to obtain N, N'-diethylglycine 4-acetylamino phenyl ester, hydrochloric acid is used for adjusting the pH to be 4, and the propacetamol hydrochloride is obtained. The preparation method has the advantages of mild condition, convenient separation and purification, the total product yield is greatly increased, the use of the amount of the reaction solvent is low, and the preparation method reduces industrial pollution, and is applicable to industrialized production.

Owner:ANHUI PIOM PHARMA

Method for extracting tannin from banana stems and fruit axes

InactiveCN102070675ATake advantage ofEasy to masterEsterified saccharide compoundsSugar derivativesChemical industrySoftened water

The invention discloses a method for extracting tannin from banana stems and fruit axes, and the method comprises the following steps: (1) collecting materials, and shredding the materials; (2) kneading into threads; (3) squeezing, and collecting a stock solution; (4) concentrating; (5) preparing an animal glue solution for later use: adding animal glue into a saturated sodium chloride solution, and heating to dissolve the animal glue; (6) preparing an ethanol solution which is composed of 45-50 parts of 95wt% ethanol, 45-50 parts of softened water and 0.5-1 part of 60wt% hydrochloric acid; (7) stirring and clarifying; (8) filtering; (9) extracting tannin; and (10) drying at a low temperature to obtain the finished tannin product. The method provided by the invention has the advantages of low development cost and low labor intensity, and is convenient and practical. By utilizing the method disclosed by the invention, wastes are changed into valuable substances, resources are fully utilized, and new raw material resources are provided for the chemical industry in China; the required equipment is simple, and can be easily mastered by common working personnel in enterprises; no chemical assistant which is harmful to the environment is needed in the extraction process; and the method disclosed by the invention breaks through the traditional plant tannin extraction process, and performs an active function for protecting the ecology.

Owner:黄一君

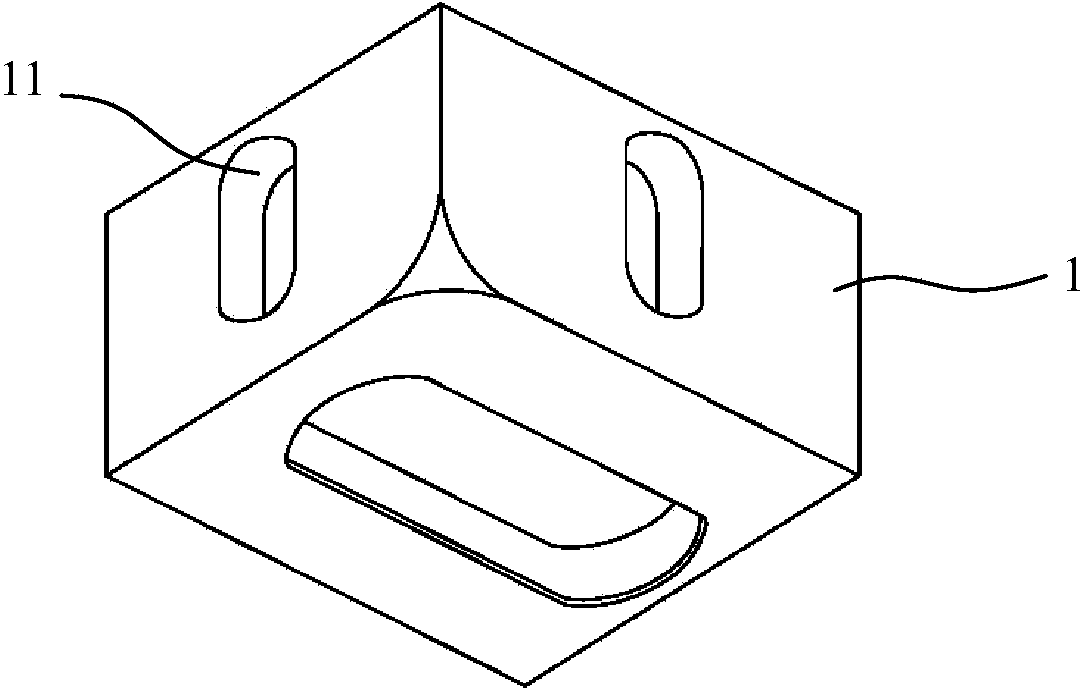

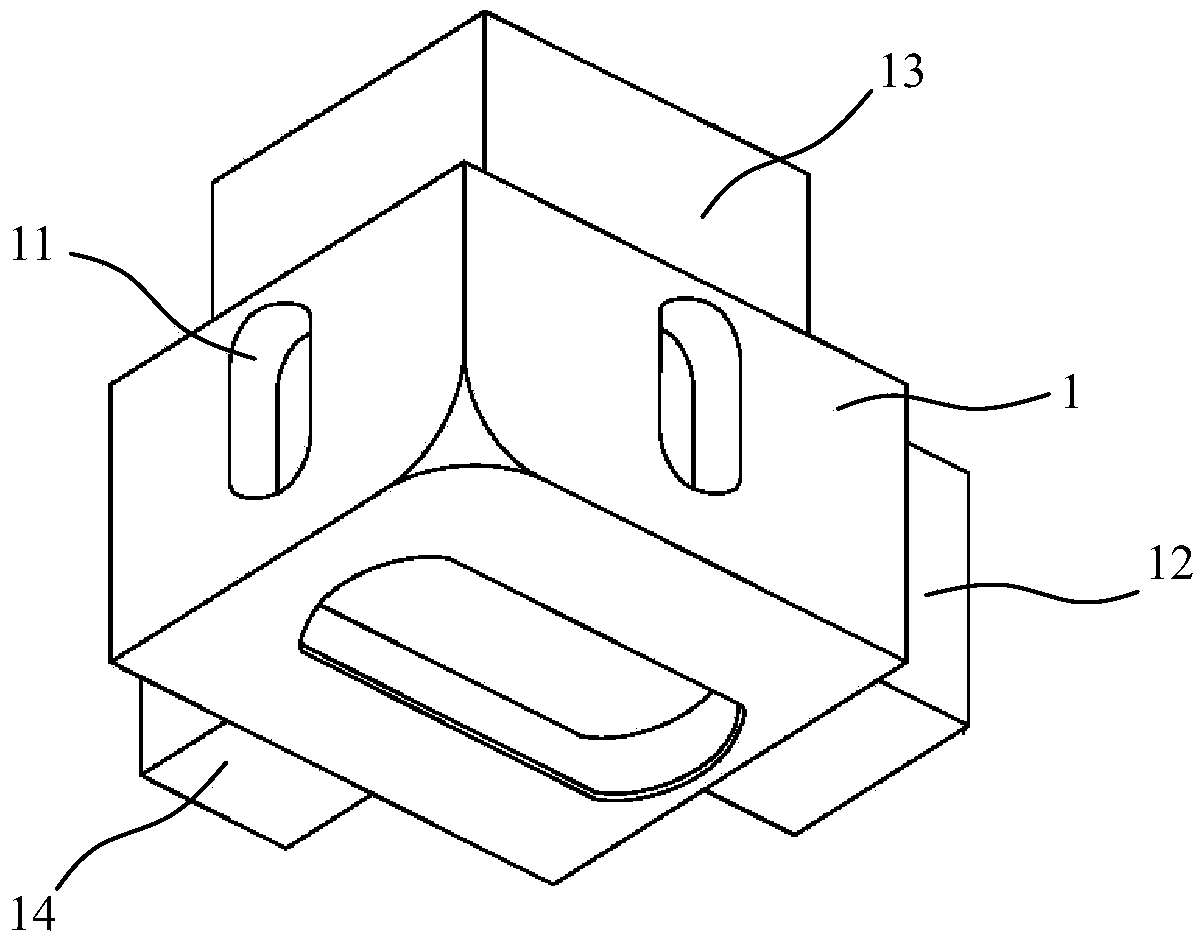

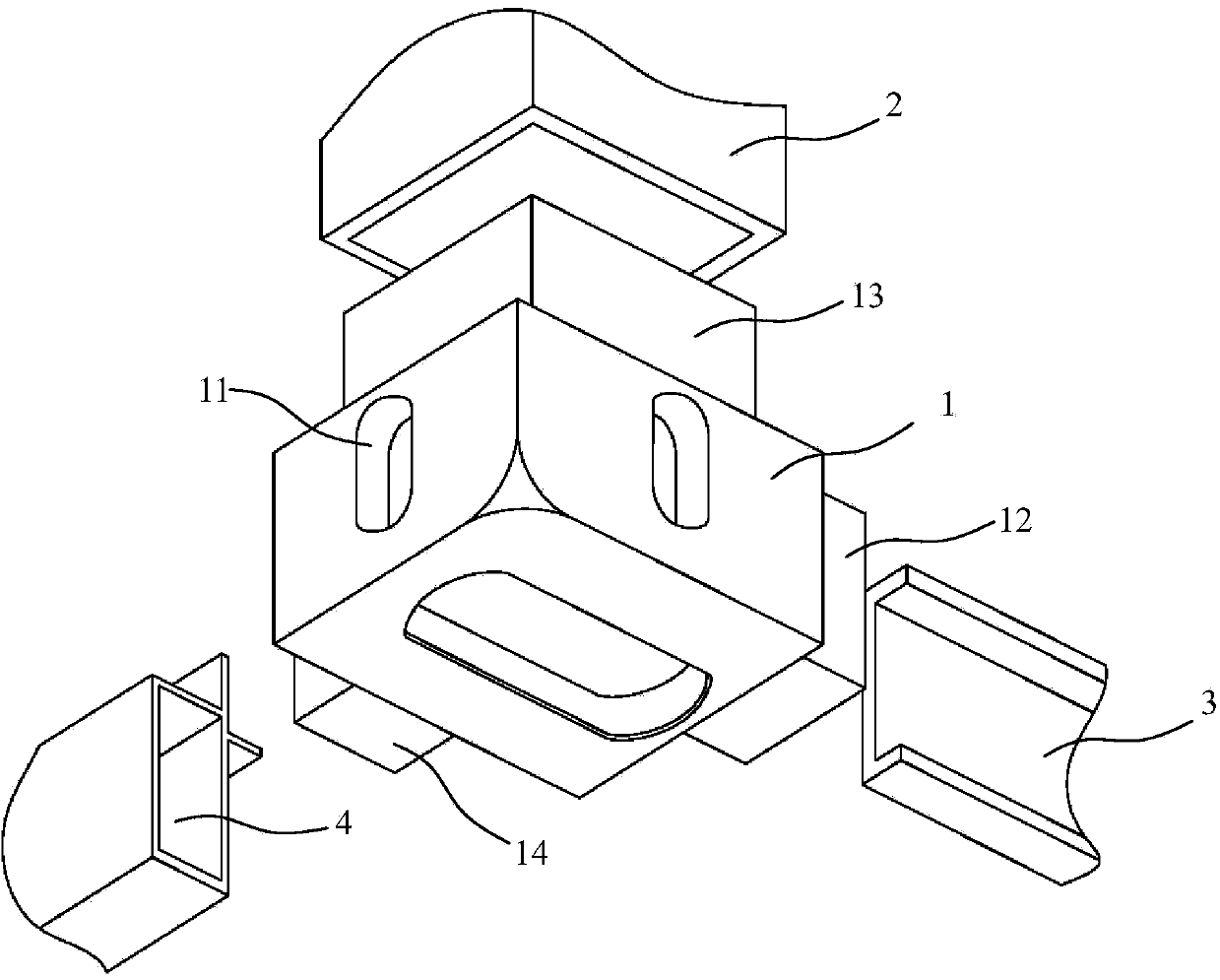

Corner fitting for container, container and container-type movable house

InactiveCN104176396ARapid productionReduce consumptionLarge containersBuilding constructionsTransportation energyAlloy

The invention discloses a corner fitting for a container, the container and a container-type movable house. A main body of the corner fitting for the container is cuboid-shaped; mounting through holes are formed in three outer end surfaces of the main body facing the outer side of the container, and the other three end surfaces of the main body can be fixedly connected with a side beam, an upright column and an end beam of the container respectively; a connecting boss is arranged on at least one end surface in the three end surfaces connected with the side beam, the upright column and the end beam of the container, can be connected with a matched beam column of the container in an insertion manner, and can be fixedly connected with the beam column of the container. According to the container and the container-type movable house with the corner fitting structure, a conventional welded structural part connecting mode can be replaced with a bond-riveted mode, the labor difficulty of a connecting process is reduced, the work efficiency is improved, and industrial pollution and energy consumption are reduced; meanwhile, a light aluminum alloy can be adopted as a base material of the container, and therefore the transportation energy consumption and the transportation cost are greatly reduced.

Owner:邵妮

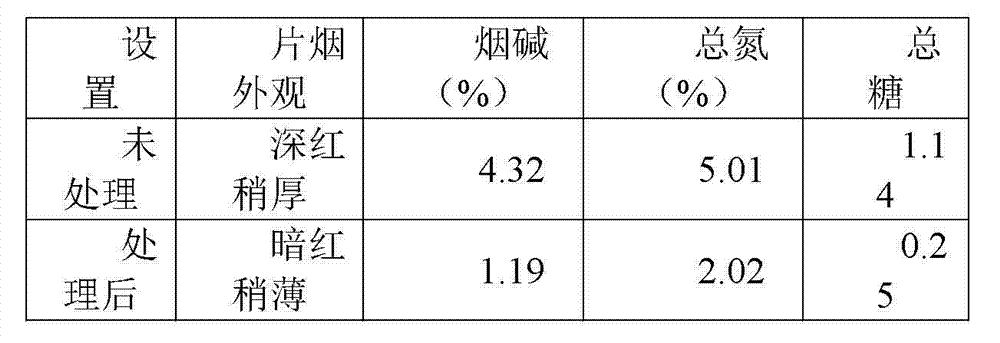

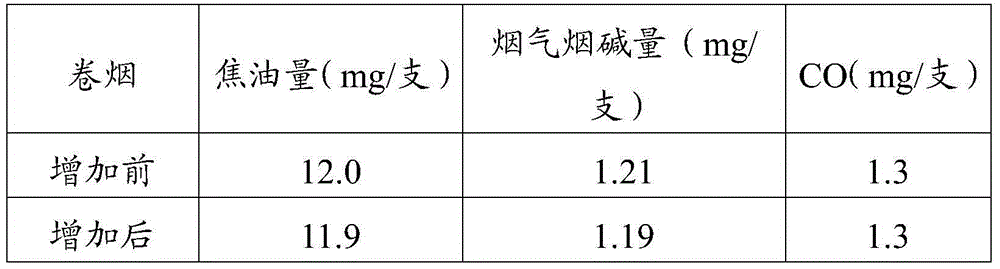

Processing and manufacturing method of burley tobaccos

The invention discloses a processing and manufacturing method of burley tobaccos. The processing and manufacturing method belongs to a processing method of materials of cigarette products. The processing and manufacturing method comprises the following steps of: soaking the burley tobaccos after threshing, rebaking and fermentation for 18-24 months by using an alcoholic solution with a mass concentration of 70%-90%, enabling a weight ratio between the burley tobaccos and the alcoholic solution for soaking the burley tobaccos to be 1:2-1:10, sequentially conducting ultrasonic processing and distillation on soaked burley tobaccos and the alcoholic solution, and draining the alcoholic solution in the burley tobaccos after distillation, stoving until a moisture content is 11-15%. The processing and manufacturing method is fewer in needed raw materials, low in cost, simple in operation process, easy to grasp and prone to convert into production lines, the burley tobaccos obtained by processing can increase usage amount of the burley tobaccos in a mixed type cigarette by 5-6%, and using ratios of the burley tobaccos are improved. The burley tobaccos processed by the method can replace 3-4% of flue-cured tobacco usage amount of a flue-cured tobacco cigarette, a usable range of the burley tobaccos is expanded, and raw material cost of the cigarette is reduced.

Owner:HUBEI CHINA TOBACCO IND

Application of electronic spot-welding technology for connecting coil winding lead of chip vibrating electric machine

InactiveCN1658476ACompletely lead-freeReduce manufacturing costWindingsManufacturing dynamo-electric machinesLacquerElectric machine

An application of spot welding technique to the down-lead connection of slice vibrant electrical loop winding, including the welding of the down-lead and double-faced PCB board. This invention does not need welding materials and plumbum; the enamel wire welding does not need pre-removing enamel cover and stannum soaking pre-processing, and reduces the industrial pollution caused by using lacquer removing solution and welding assistant. This invention uses half-mechanization of electronic spot welding machine, avoids the weak points of the hand welding operation, and effectively prevent of bad contact phenomenon. Therefore, this invention not only reduces the cost, but also improves the working efficiency and greatly increases the eligible ratio of the welding.

Owner:程浩川

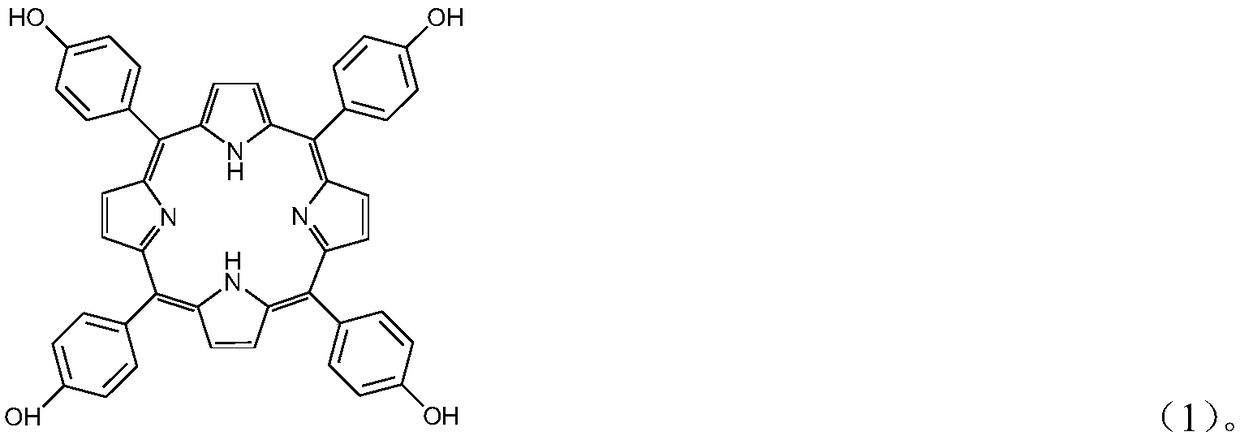

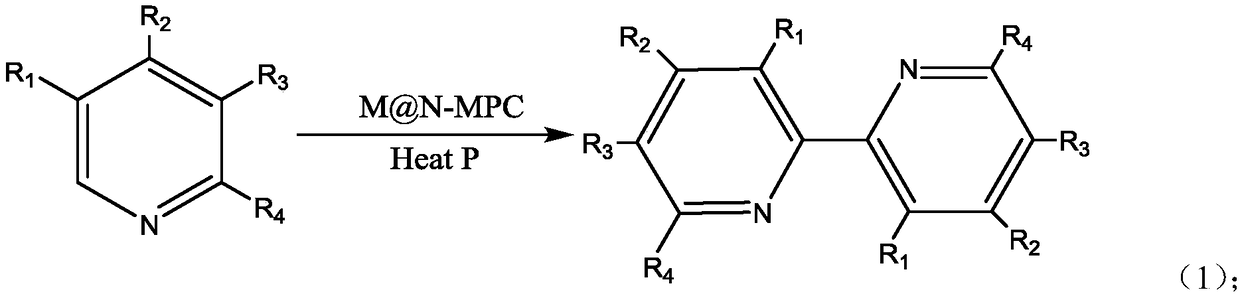

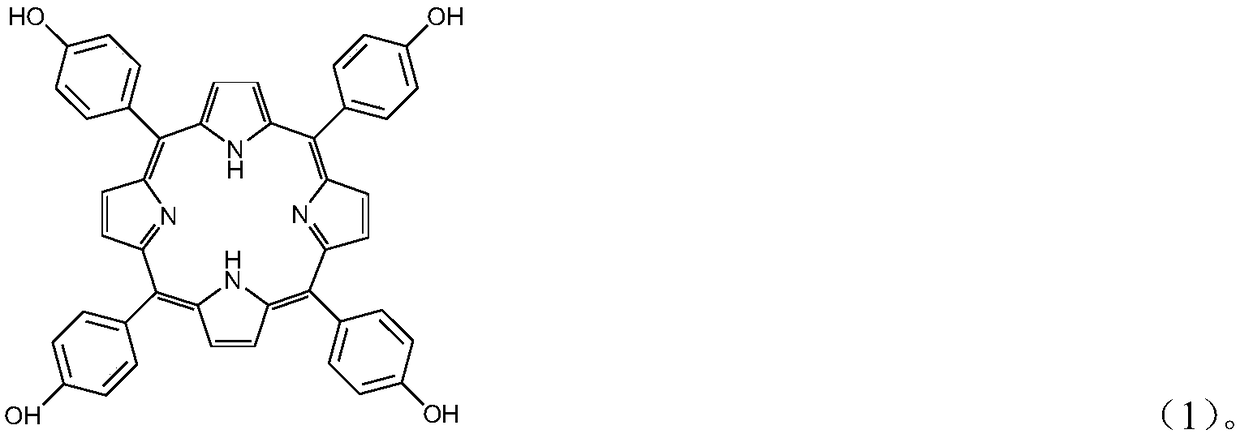

Preparation method and application of N-doped mesoporous-carbon-loaded metal nano-catalyst

ActiveCN109482235AImprove stabilityMild conditionsOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsNano catalystPorphyrin

The invention discloses a preparation method and application of an N-doped mesoporous-carbon-loaded metal nano-catalyst. The preparation method comprises the steps of with a metal 5,10,15-20-tetra(4-hydroxyphenyl)porphyrin complex (M-THPP for short) as a starting material and a metal covalent organic framework polymer prepared through condensation polymerization of formaldehyde as a precursor, carrying out hydro-thermal synthesis and annealing, so as to obtain the N-doped mesoporous-carbon-loaded metal nano-catalyst M@N-MPC, wherein the nano-catalyst can be directly used for directly couplingpyridine to generate 2,2'-bipyridine, and M can be mono-metal and duplex metal. By virtue of a coordination effect of the catalyst precursor and carrier nitrogen, the metal active components, namely nano-particles are small in particle size and uniformly dispersed and have high catalytic activity to the reaction for directly coupling pyridine to synthesize dipyridyl, the reaction conditions are relatively mild, and the single-pass conversion rate is high; and meanwhile, the carbon catalyst carrier is high in stability and good in recycling cycle performance in a pyridine alkali wash reaction system and is particularly suitable for large-scale industrial production.

Owner:HEFEI UNIV OF TECH

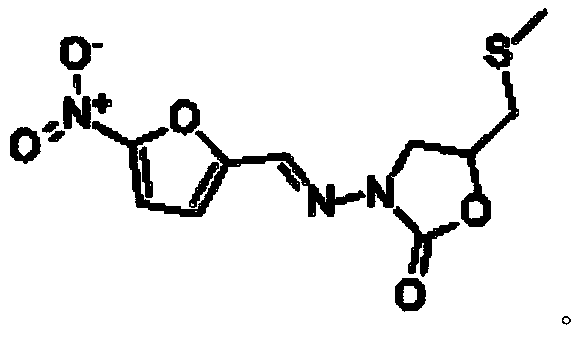

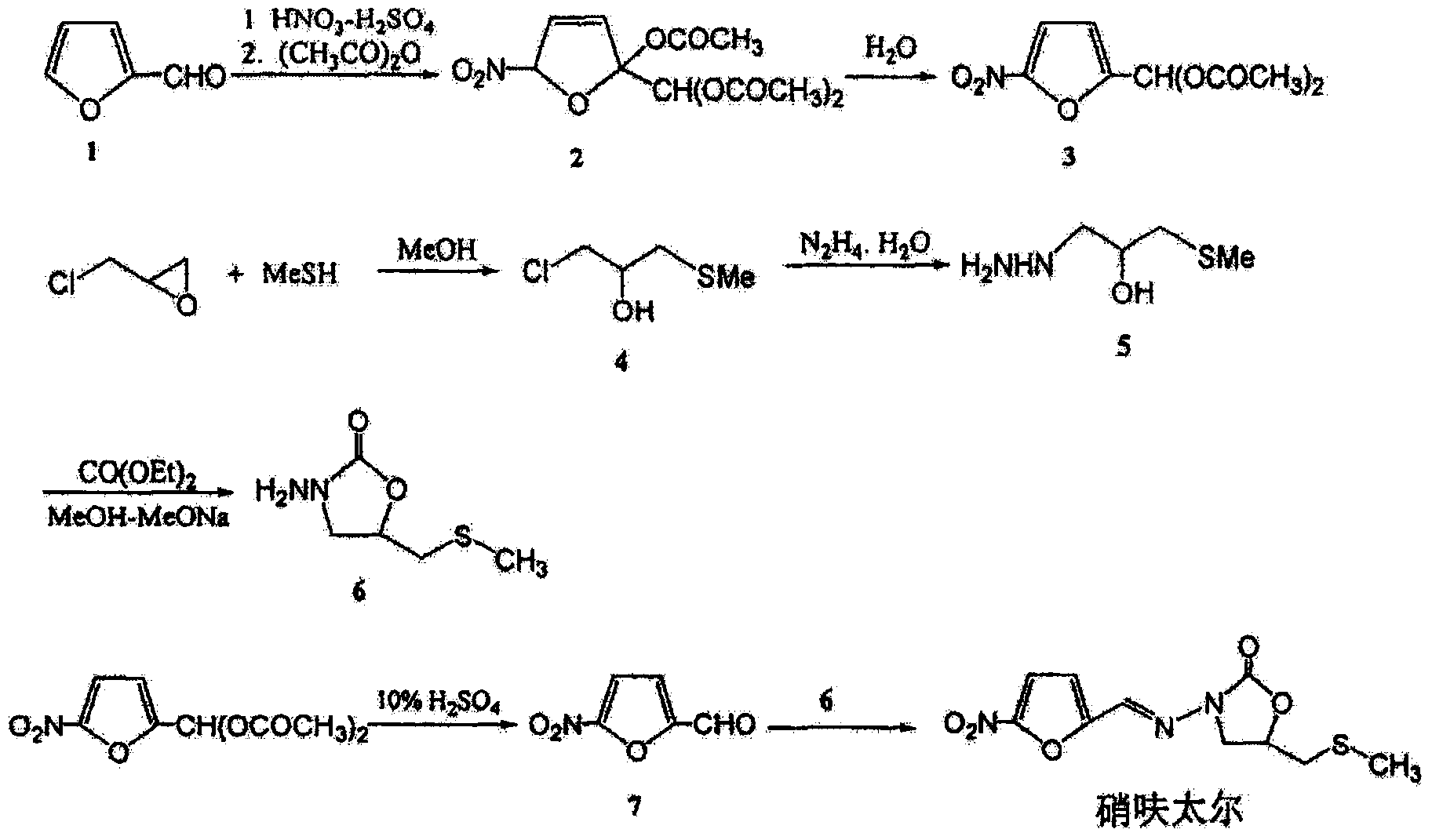

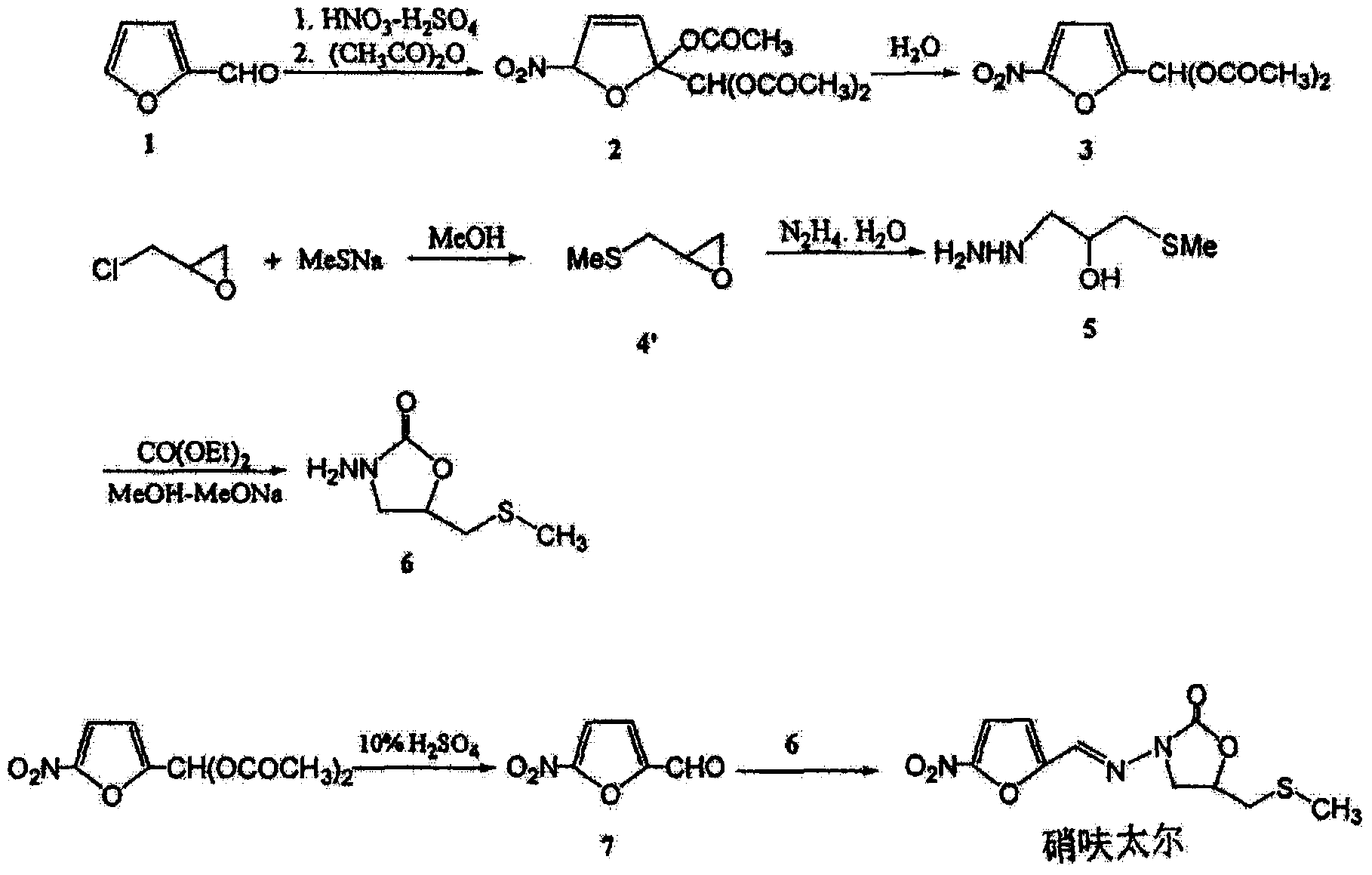

Synthetic method of nifuratel

The invention discloses a synthetic method of nifuratel. The synthetic method comprises the steps of carrying out a substitution reaction between epoxy chloropropane and sodium methyl mercaptide in the presence of a phase transfer catalyst to obtain epoxy propyl dimethyl sulfide, and then performing hydrazinolysis, cyclization and condensation on the obtained epoxy propyl dimethyl sulfide to obtain the nifuratel. The synthetic method is high in nifuratel yield, high in purity and low in impurity content; besides the method has the advantages that a ring-closure reaction is carried out under the alkaline condition of sodium methoxide, the use of metal sodium is avoided, production safety is ensured, and simultaneously, the reaction is easy to arouse, easy to control in process, the used raw materials are easy to get, basically no waste liquid is generated in the reaction of each step, and therefore, industrial pollution is greatly reduced; and as a result, the synthetic method of nifuratel is applicable to industrial production.

Owner:BEIJING CHENGYI INVESTMENT CO LTD

Crane girder

InactiveCN102674151AReduce initial investmentSmall wheel pressureLoad-engaging girdersSheet steelEngineering

The invention discloses a crane girder. The crane girder comprises a girder, wherein supporting pedestals are fixed at two ends of the lower part of the girder made of a rectangular pipe; a pull rod passes through the middle part of the supporting pedestals at the two ends of the girder and is fixed by a tensioning nut; the rectangular pipe is subjected to one-step parabolic formation by an arch raising machine; the supporting pedestals fixed at the two ends of the girder made of the rectangular pipe are connected through a high-strength hinged bolt; the pull rod can also adopt a guy cable; and a thin steel plate cover with the same width as that of the girder is arranged at the lower part of the girder. The crane girder has the following effects that: welding deformation is reduced; almost no welding stress exists; the problem that the camber of the conventional girder is gradually reduced because the welding stress releases is solved; the self weight of the crane is 15 to 20 percent lighter than that of the conventional crane, so the problem about the initial investment of users is solved; and the wheel pressure is low, so the service life of a workshop is prolonged, the building cost of the workshop is reduced, welding materials such as welding rod flux and the like are greatly saved, industrial pollution is reduced and the manual manufacturing cost is reduced.

Owner:河南中州起重集团有限公司

Method for extracting chlorophyll from luffa leaf

ActiveCN103626779AImprove effective utilizationImprove extraction efficiencyOrganic chemistryNatural dyesUltrasonic assistedDistillation

The invention discloses a method for extracting chlorophyll from a luffa leaf. The method comprises the following steps: using hydrous ethanol as an extractant, and extracting natural chlorophyll from the luffa leaf through adopting an ultrasonic-assisted extraction technology. The specific technological processes are that the luffa leaf is ground, 60-80 % hydrous ethanol is added according to the feed liquid ratio of 1:(20-40), and through the adoption of the ultrasonic-assisted extraction technology, the extract liquid is subjected to reduced pressure distillation after being filtered to obtain the chlorophyll extract. Through the adoption of the method, the original extracting technology of harmful solvents such as acetone is changed, the industrial pollution is reduced, and ethanol replaces original toxic solvents, so that not only is the extracting efficiency improved effectively, but also the injury to a human body of harmful substances is reduced greatly.

Owner:ANHUI FINDSHE BIOLOGICAL PHARMA CO LTD

Papermaking method with bagasse as raw material

InactiveCN107881836AReduce development costsTake advantage ofNon-fibrous pulp additionPaper/cardboardPapermakingGrinding process

The invention discloses a papermaking method with bagasse as a raw material. The method takes the bagasse as the raw material and comprises the following steps of material collecting and edge breaking; chopping; thread rolling; pulp washing; grinding; pulp forming; dosing; pulp boiling and papermaking. The method is a papermaking method with low development cost, convenience, practicality, and lowlabor intensity and using the bagasse as the raw material. The method turns waste into wealth, takes full advantage of resources, and provides a new raw material resource for papermaking industry; the required equipment is simple, and common enterprise workers can easily master the method; there is no need to add any chemical additive during pulping and grinding processes; the method plays a positive role in reducing cutting down forest due to papermaking demands and protecting ecology; the method breaks through traditional papermaking technologies and takes full advantages of the bagasse; the method is a pure natural and 'three waste' discharge-free papermaking technology.

Owner:南宁科城汇信息科技有限公司

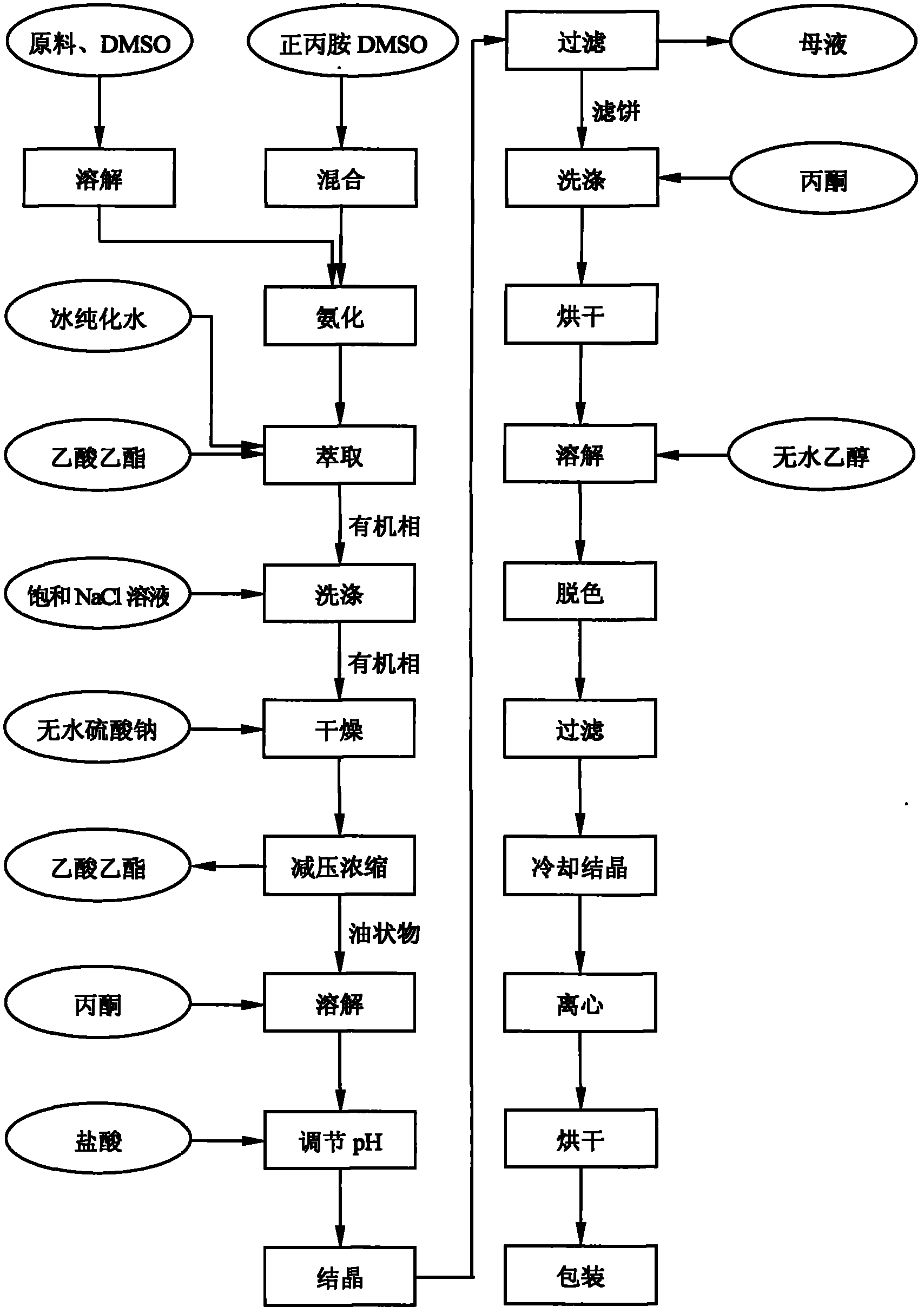

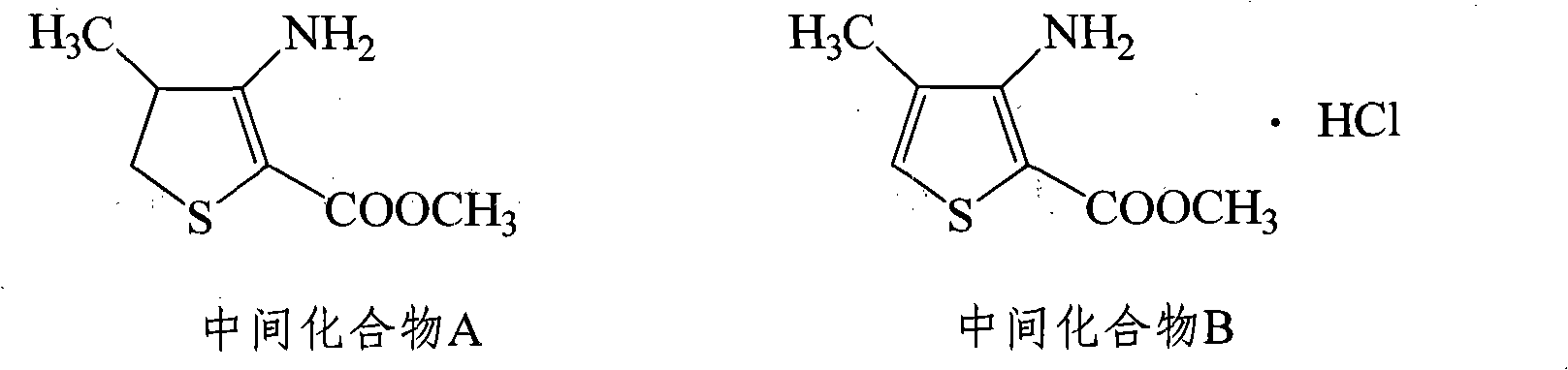

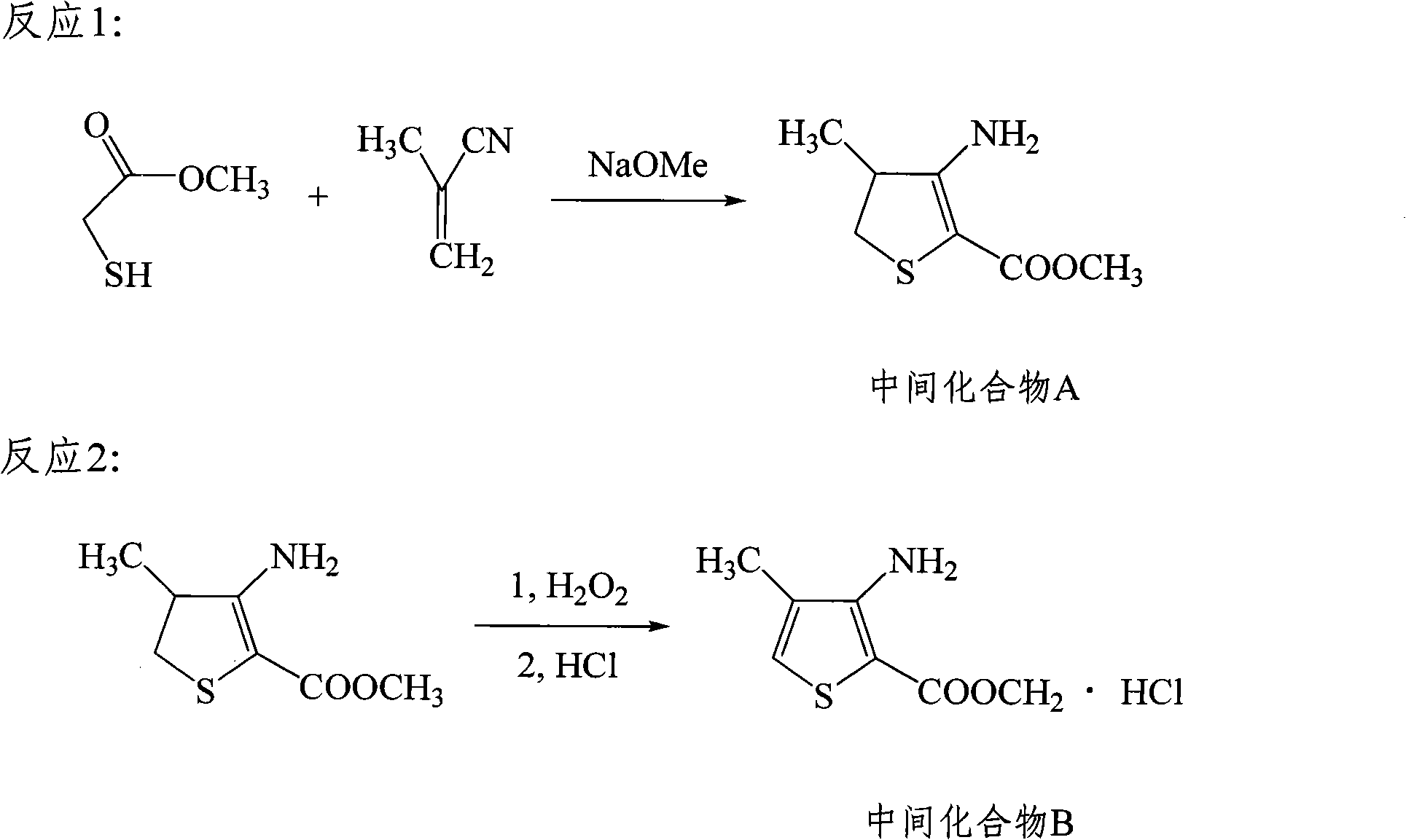

Preparation method of articaine hydrochloride

The invention provides a preparation method of articaine hydrochloride. The preparation method comprises the following steps of: reacting methyl mercaptoacetate with 2-metyl acrylonitrile used as starting raw materials in a mixed solution of sodium methoxide and methanol, after the reaction is finished, adjusting the pH value to 7 with concentrated hydrochloric acid, dropwise adding hydrogen peroxide, then dropwise adding concentrated hydrochloric acid to the reaction system, and concentrating under reduced pressure to obtain an intermediate compound B; dissolving the compound B in dichloromethane containing pyridine, dropwise adding alpha-chloropropionyl chloride, washing the reaction product, drying and concentrating to obtain an intermediate compound C; and dissolving the compound C with dimethyl sulfoxide, dropwise adding to a dimethyl sulfoxide solution containing n-propylamine, reacting at room temperature, mixing the product with ice water, extracting with ethyl acetate, drying, concentrating to obtain an oil product, dissolving with acetone, adjusting the pH value to 5-6 with concentrated hydrochloric acid, crystallizing, filtering and drying to obtain a crude product of the articaine hydrochloride. The method has the advantages that the operation is easy, the separation and purification are convenient, the product yield is high, the product purity is more than 99%, the industrial pollution is low, and the method is suitable for mass production.

Owner:蚌埠丰原涂山制药有限公司

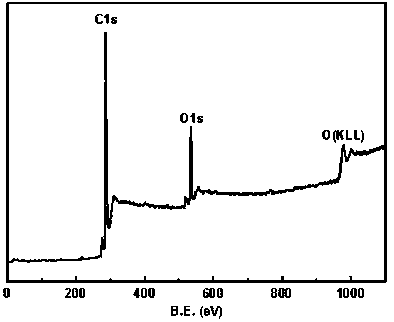

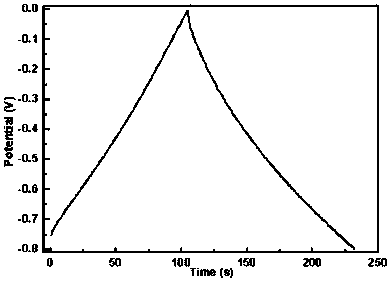

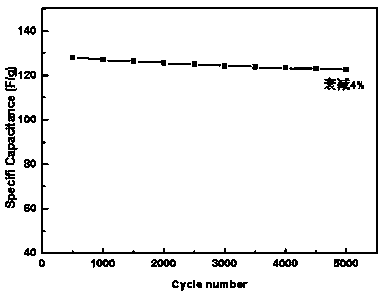

Preparation method and application of oxygen-containing porous carbon aerogel

ActiveCN110143582ARich in holesIncrease the areaHybrid capacitor electrodesCarbon preparation/purificationCellulosePorous carbon

The invention relates to a preparation method of oxygen-containing porous carbon aerogel, comprising the following steps: obtaining porous carbon aerogel through a conventional method, dispersing theporous carbon aerogel material in an aqueous solution of H2O2 and FeCl3 according to the concentration of 0.2-0.3 mg / ml with the molar ratio of H2O2 to FeCl3 being 1:1-1:4, uniformly stirring and mixing, adjusting pH to 2-4 by using a NaOH solution, treating by a plasma technology, carrying out suction filtration by using a mixed cellulose filter membrane after the reaction, washing with lots of deionized water to neutral level, collecting a powder, drying and grinding. The porous carbon aerogel provided by the invention has rich oxygen-containing functional groups, which can enhance wettability of the porous carbon aerogel in an electrolyte and can provide a pseudocapacitor having high capacitance.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

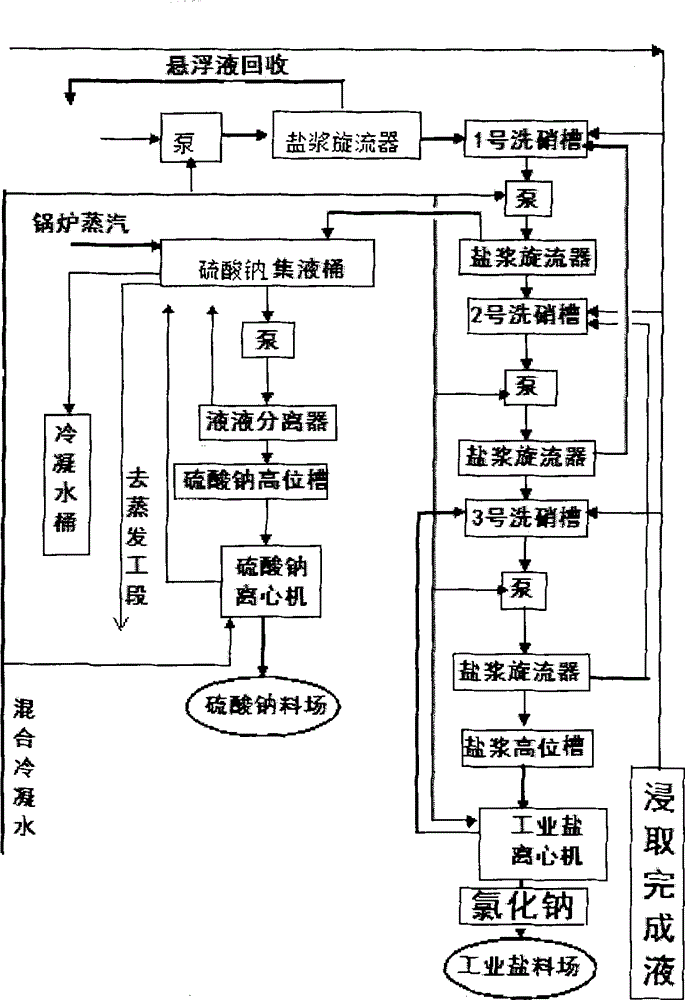

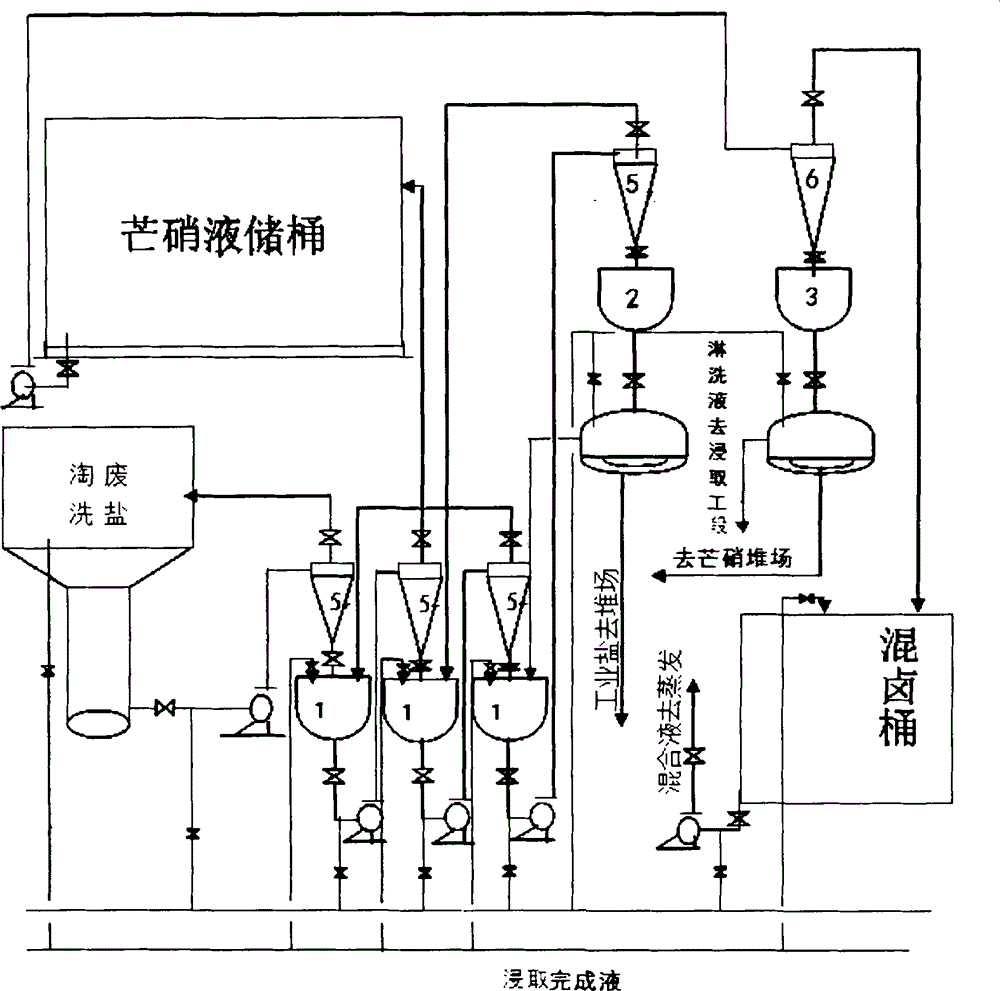

Production process of temperature-controlled cyclic layer-by-layer sodium nitrate separation

ActiveCN104591229ASave heatReduce water consumptionAlkali metal nitrate purificationAlkali metal sulfite/sulfate purificationTemperature controlEvaporation

The invention discloses a production process of temperature-controlled cyclic layer-by-layer sodium nitrate separation. The production process comprises the following steps: soaking nitronatrite ore with water to form a three-salt system liquid of sodium chloride NaCl, sodium nitrate NaNO3 and sodium sulfate Na2SO4; producing sodium chloride by low-temperature salt slurry whirl in the heating treatment process; extracting sodium sulfate from high-temperature salt slurry by virtue of a liquid-liquid separator; and returning a mother liquid to an evaporation system to use in cycle, and gradually separating and washing a salt slurry separator, so that heat energy is reduced; the water consumption is reduced; industrial pollution is reduced; the production process is mainly applied to comprehensive utilization of nitronatrite ore resources; production of the sodium nitrate is achieved; by-production of the sodium chloride and the sodium sulfate is achieved; waste salt is divided into two products, namely the sodium sulfate and the sodium chloride, so that the production value is increased; and the comprehensive economic benefits are improved.

Owner:TURPAN BRANCH OF SINKIANG NITRATE MINERALS

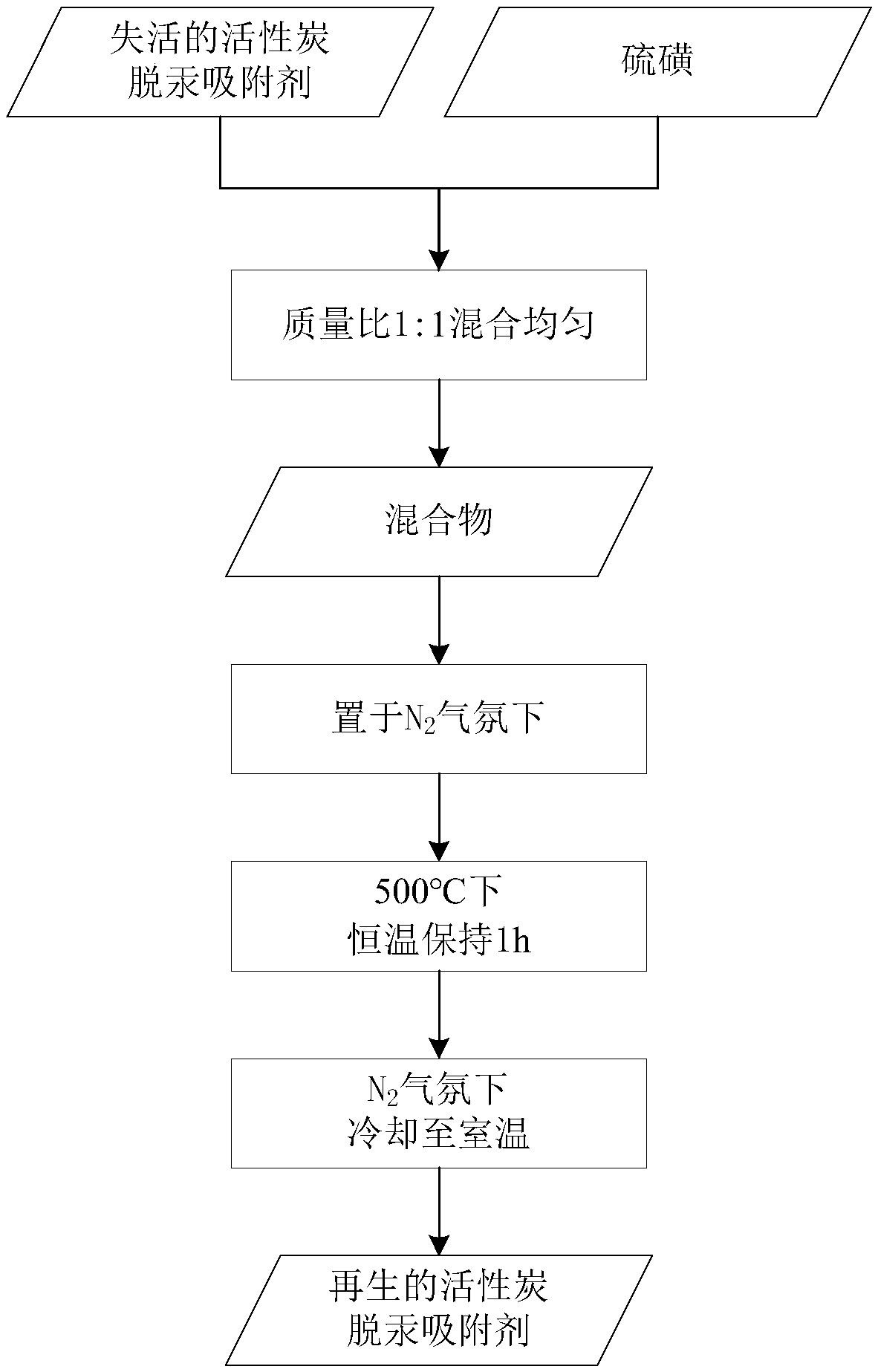

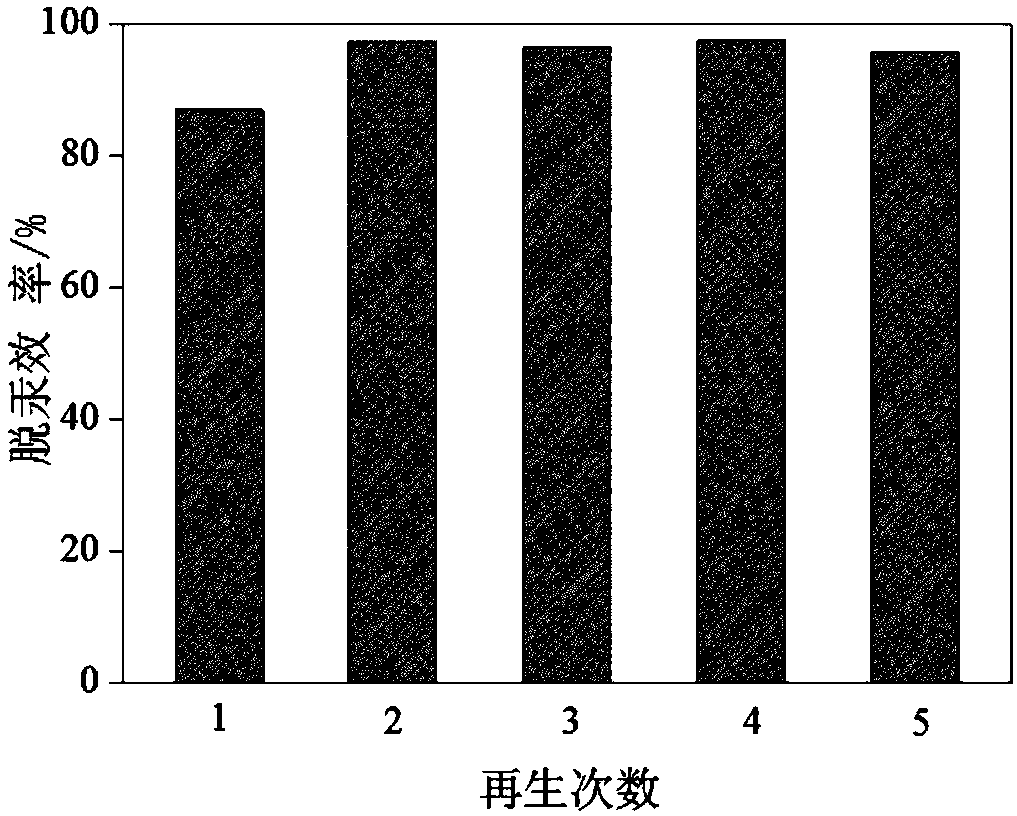

Sulfur-loaded heat regeneration method of active carbon mercury removal adsorbing agent

ActiveCN108579711AConducive to the realization of recyclingSimple processGas treatmentOther chemical processesSorbentMercury adsorption

The invention provides a sulfur-loaded heat regeneration method of an active carbon mercury removal adsorbing agent. The method includes the steps: uniformly mixing inactivated active carbon mercury removal adsorbing agents and sulfur elementary substances according to the weight ration of (0.5-2):1 to obtain mixture; keeping the constant temperature for 0.5-3h at the reaction temperature of 400-700 DEG C under inert gas atmosphere; stopping heating under protection of the inert gas atmosphere, and cooling mixture to reach indoor temperature to achieve sulfur-loaded heat regeneration of the active carbon mercury removal adsorbing agent. The method is simple in process and low in cost and has strong mercury adsorption property and cyclic regeneration characteristics, holes of regenerated adsorbing agents can be developed, and the surfaces of the regenerated adsorbing agents are rich in a lot of sulfur-containing functional groups.

Owner:DATANG ENVIRONMENT IND GRP +1

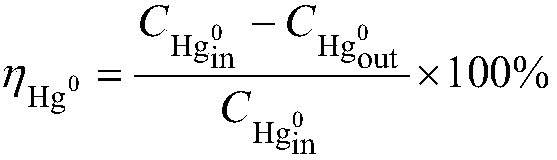

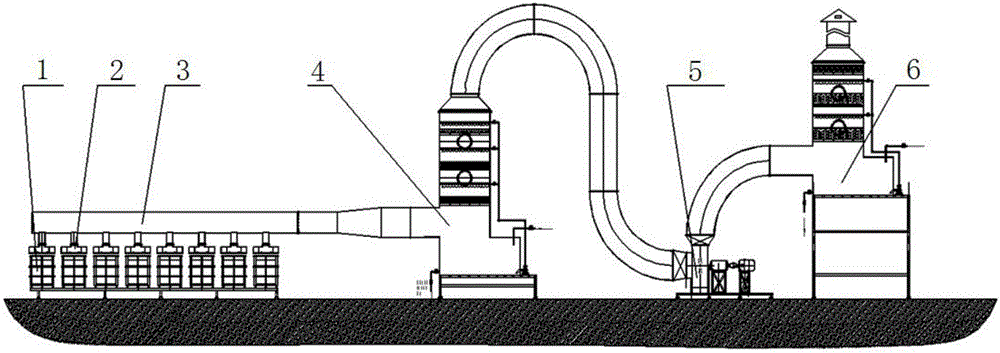

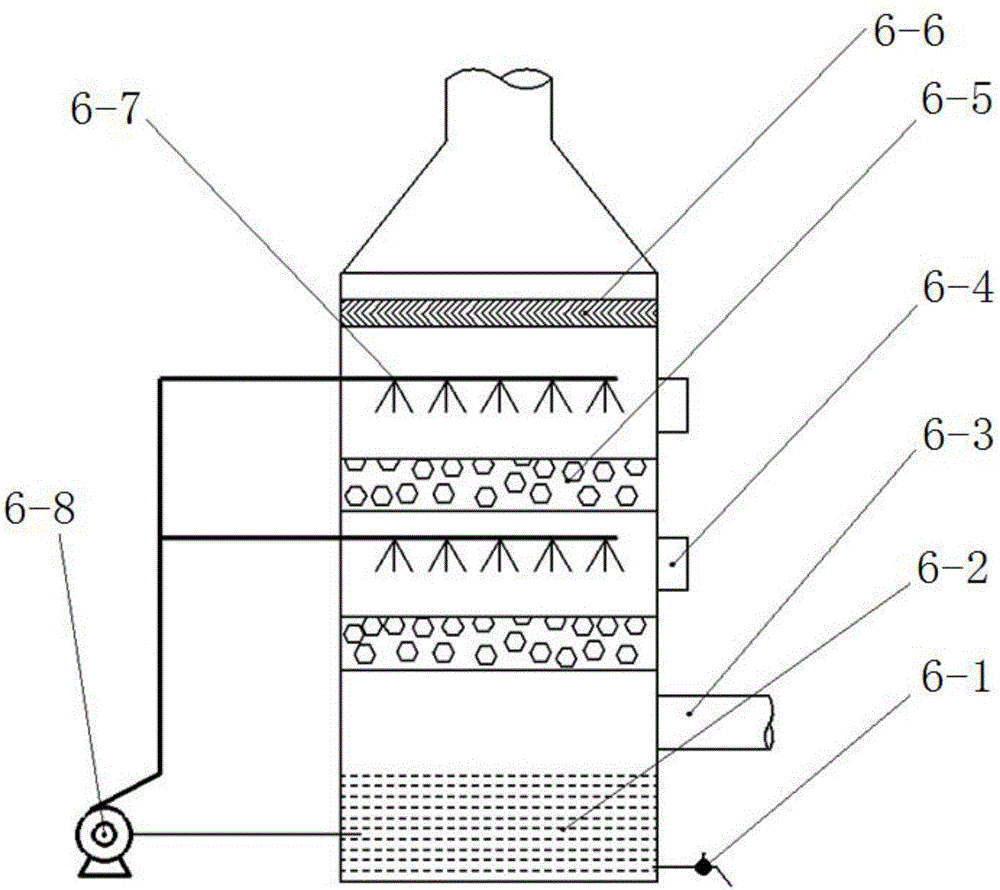

Chromium fog recovery system for piston rod chromium plating production line

InactiveCN106835254AReduce wasteReduce pollutionCellsCombination devicesSocial benefitsProduction line

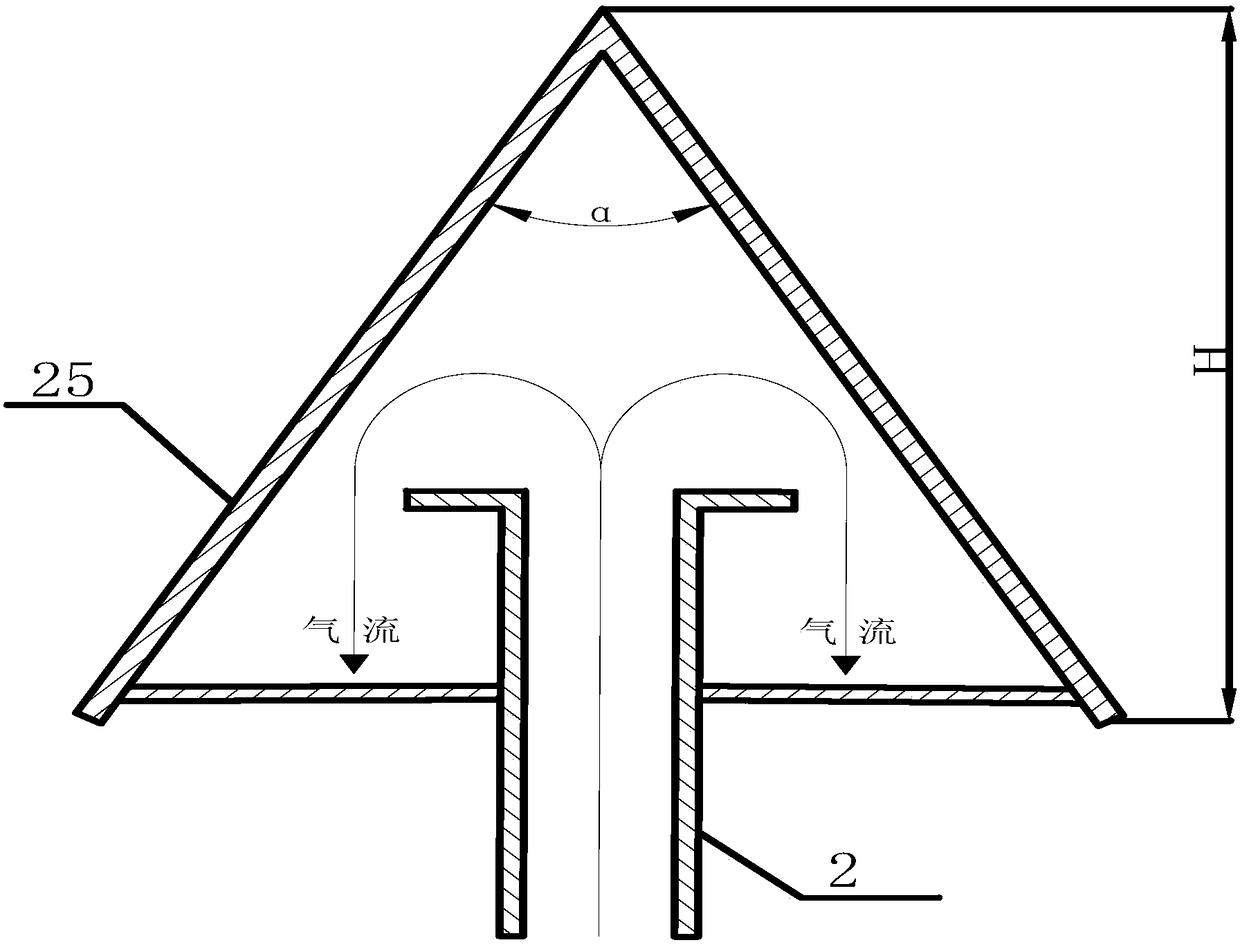

The invention discloses a chromium fog recovery system for a piston rod chromium plating production line. The system comprises an electroplating bath (1), an exhaust hood (2), a ventilation pipeline (3), a chromium fog recovery device (4), a ventilation fan (5) and a turbulent ball purification tower (6), wherein the exhaust hood (2) is arranged above the electroplating bath (1) and used for collecting chromium fog produced by the electroplating bath (1); the exhaust hood (2) is communicated with the ventilation pipeline (3), the ventilation pipeline (3) is communicated with an inlet end of the chromium fog recovery device (4), an outlet end of the chromium fog recovery device (4) is communicated with the ventilation fan (5), and chromium fog is delivered to the chromium fog recovery device (4) under the action of the ventilation fan (5); an outlet of the ventilation fan (5) is connected with an input air pipeline of the turbulent ball purification tower (6). The chromium fog recovery system can effectively reduce waste of raw material chromic anhydride for chromium electroplating, protect personal safety of operators, reduce industrial pollution and increase the economic benefit and social benefit.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Industrial fermentation ramee rapid extraction technique for Erwinia

ActiveCN101235357BIncrease enzyme activityUnique and distinct color responseBacteriaMutant preparationAnimal ForagingHigh pressure

The invention discloses a technique for rapidly extracting ramie hemp erwinia bacterium factory production fermentation, the technique comprises preprocessing material, immersing or sprinkling and inoculating, immersing or fermenting, deactivating with hot water, and the procedure of circulation washing, water dressing and fiber finish, erwinia bacterium which has broad-spectrum and high effective to degumming, pulping and saccharifying of herb fiber material, and bacterial agent preparation and activated technical parameter. The erwinia bacterium addicts the mannose, the peak for secreting non-cellulose to degrade key enzyme (pectic enzyme, beta-mannase and xylanase) can be achieved through purely culturing for 7h to 9h. Bacterial agent is inoculated on herb fiber material such as ramie and the like for activating the bacterial agent for 5h-6h, fermentation forage fodder turns to blue after fermenting for 5h-6h, pectine, hemicellulose and partial lignin which are partially degraded and associated in fiber cell are stripped, non-cellulose residues which are absorbed on fiber can be removed by means of the flushing of high-pressure flushing, and the purpose of extracting net fiber can be reached.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

Dry gear cutting technology of helical bevel gear

ActiveCN101704135AReduce industrial pollutionImprove processing efficiencyHeat treatment process controlGear teethRound barGear cutting

The invention relates to a dry gear cutting technology of a helical bevel gear, comprising the following steps: adopting round bar steel stamping with the outer diameter of 60-180mm for shaping, selecting a K-class superfine hard alloy cutter, heating a workpiece to 920-950 DEG C, preserving the temperature for 2-4h, cooling the temperature to 540-680 DEG C by air, preserving the temperature for 2-4h, cooling naturally to room temperature, lathing the workpiece after normalizing treatment to the required dimension of the gear, performing gear cutting, lathing, detecting and warehousing. The invention completely adopts dry gear cutting without the need of cutting oil and surface cleaning before heat treatment, thus reducing industrial pollution, improving processing efficiency, lowering production cost, having high precision of product gear cutting processing and short technology flow.

Owner:ZHUZHOU GEAR CO LTD

Compound biomass fuel containing sepiolite as well as preparation method of fuel

InactiveCN105219471ARaise the combustion temperatureImprove combustion efficiencyBiofuelsSolid fuelsDry weightEngineering

The invention discloses compound biomass fuel containing sepiolite as well as a preparation method of the fuel. The compound biomass fuel containing the sepiolite comprises components in parts by dry weight as follows: 40-70 parts of agricultural and forestry residues, 10-20 parts of humus layer soil, 20-40 parts of waste tire rubber and 10-20 parts of a compound combustion improver; the compound combustion improver comprises components in parts by weight as follows: 80-120 parts of sepiolite powder, 10-20 parts of basic cupric carbonate, 10-20 parts of coal slime, 10-20 parts of sodium nitrate, 20-30 parts of black shale and 3-7 parts of manganese oxide. The biomass fuel has the high combustion temperature of 1550-1600 DEG C and the combustion efficiency about 40% higher than that of common biomass fuel; the calorific value can reach 4900-5300 kcal / kg, and 1 ton of biomass fuel is equivalent to 0.7 ton of standard coal; combustion tail gas conforms to related national regulations, the desulfurization rate can reach 98%, and the denitration rate can reach 95%.

Owner:明光市龙腾矿物有限公司

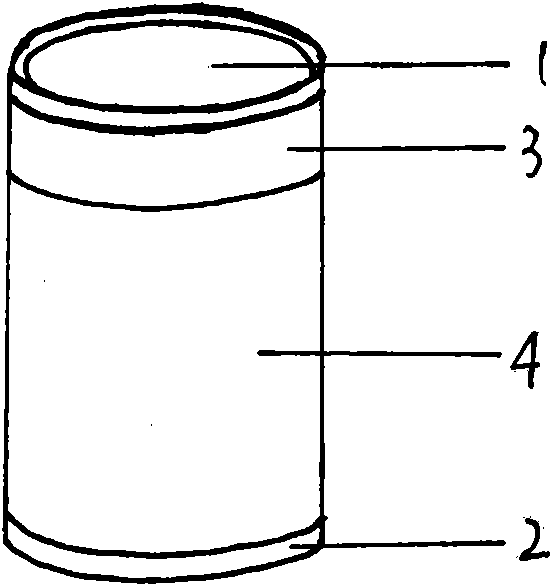

Bamboo-shell tea canister

InactiveCN102133965AAvoid bad smellBad smell is notFlexible coversWrappersEngineeringVegetable material

The invention relates to a bamboo-shell tea canister, which is made by the steps of making a cylinder from a natural bamboo shell instead of a paper cylinder material, adhering color paper on the outer wall of the canister, compacting and tightly embedding a cylinder iron sheet base and a bamboo shell on the canister bottom and the canister cover bottom, and tightly adhering the superposed parts of the bamboo shell, wherein the adhering substance is a vegetable material. The made tea canister is nonpoisonous and odorless and is most suitable for containing tea.

Owner:罗林松

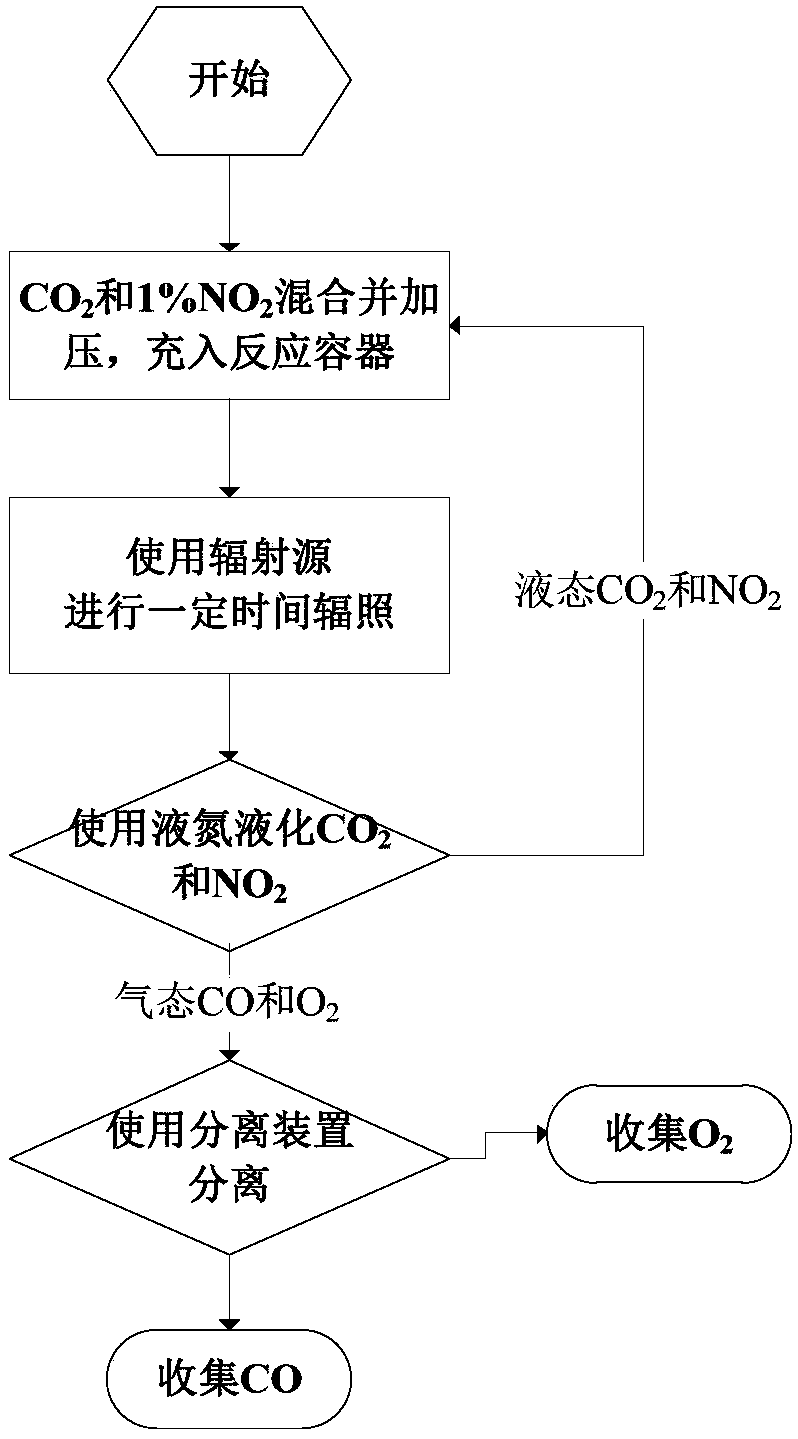

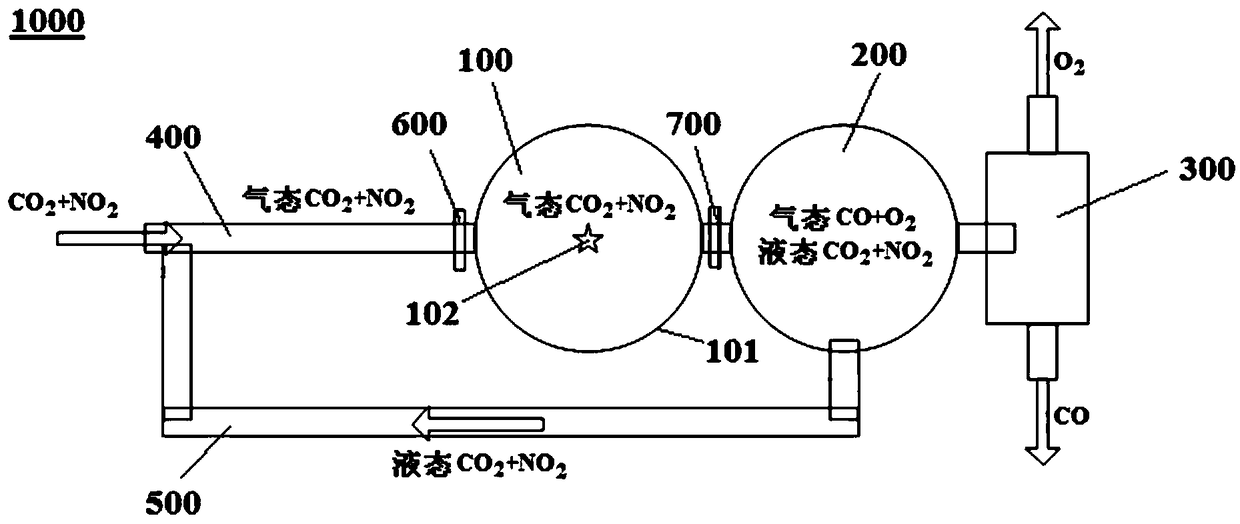

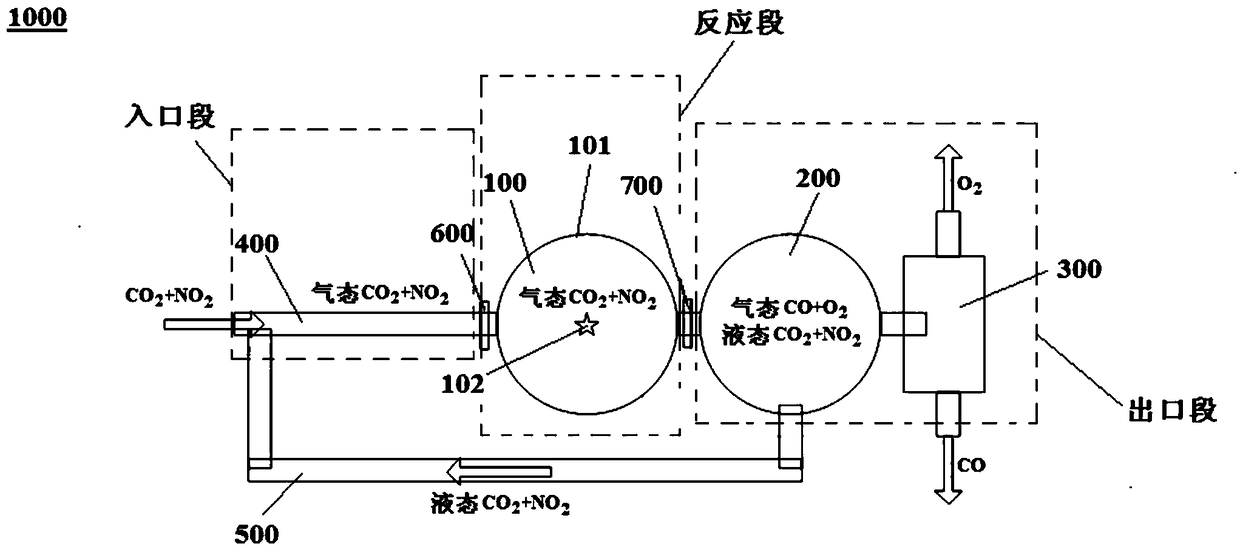

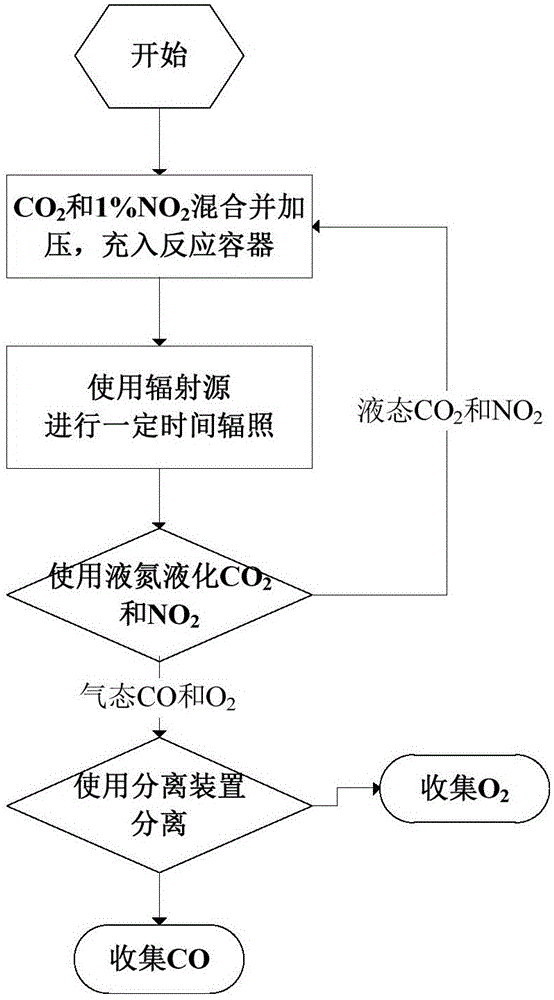

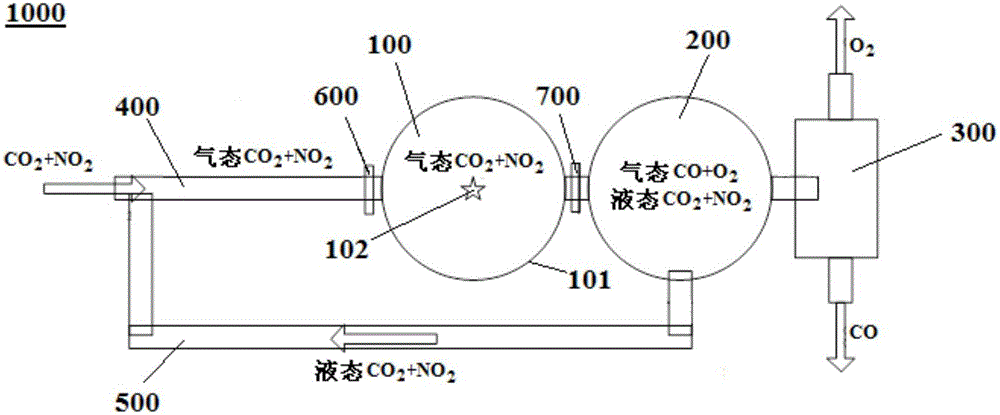

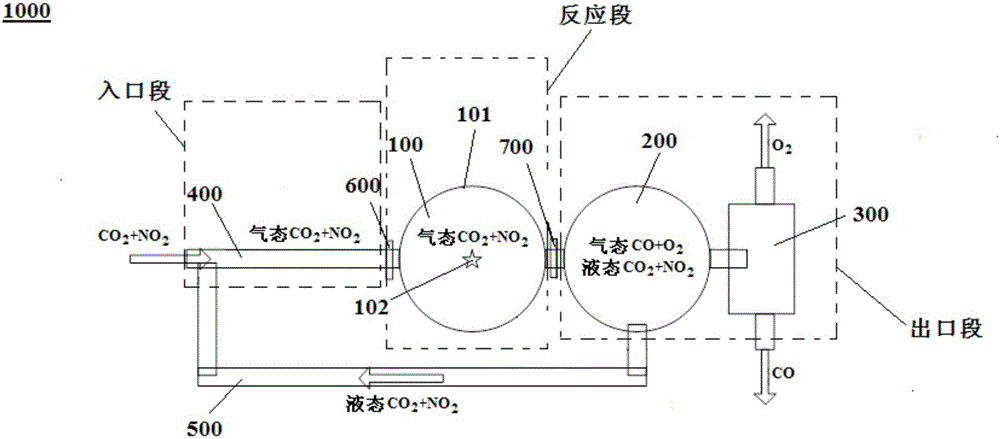

Method, system and use for decomposing co2

ActiveCN105905900BTake advantage ofReduce industrial pollutionSolidificationLiquefactionDecompositionEnergy consumption

The invention discloses a CO2 decomposing method, a CO2 decomposing system and application thereof. The CO2 decomposing method includes: putting CO2 in a radiation range of a radiation source so as to utilize ionizing radiation to decompose CO2 into CO and O2. By the CO2 decomposing method, CO2 decomposition can be realized effectively to obtain CO and O2 having industrial application value; besides, devices or materials releasing ionizing radiation are fully utilized, waste recycling is realized and equivalent to zero energy consumption, cost is low, and efficiency is high.

Owner:TSINGHUA UNIV

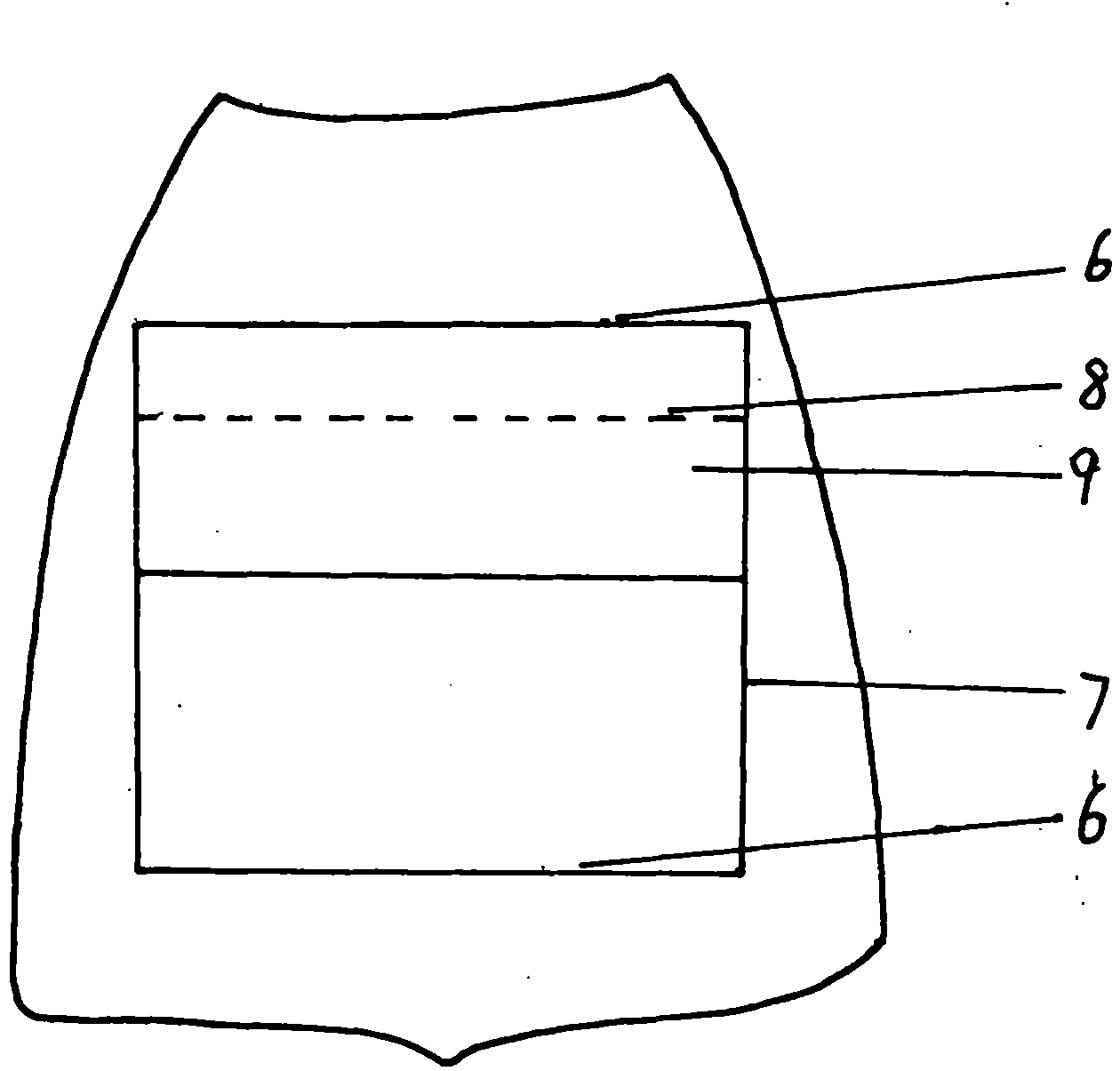

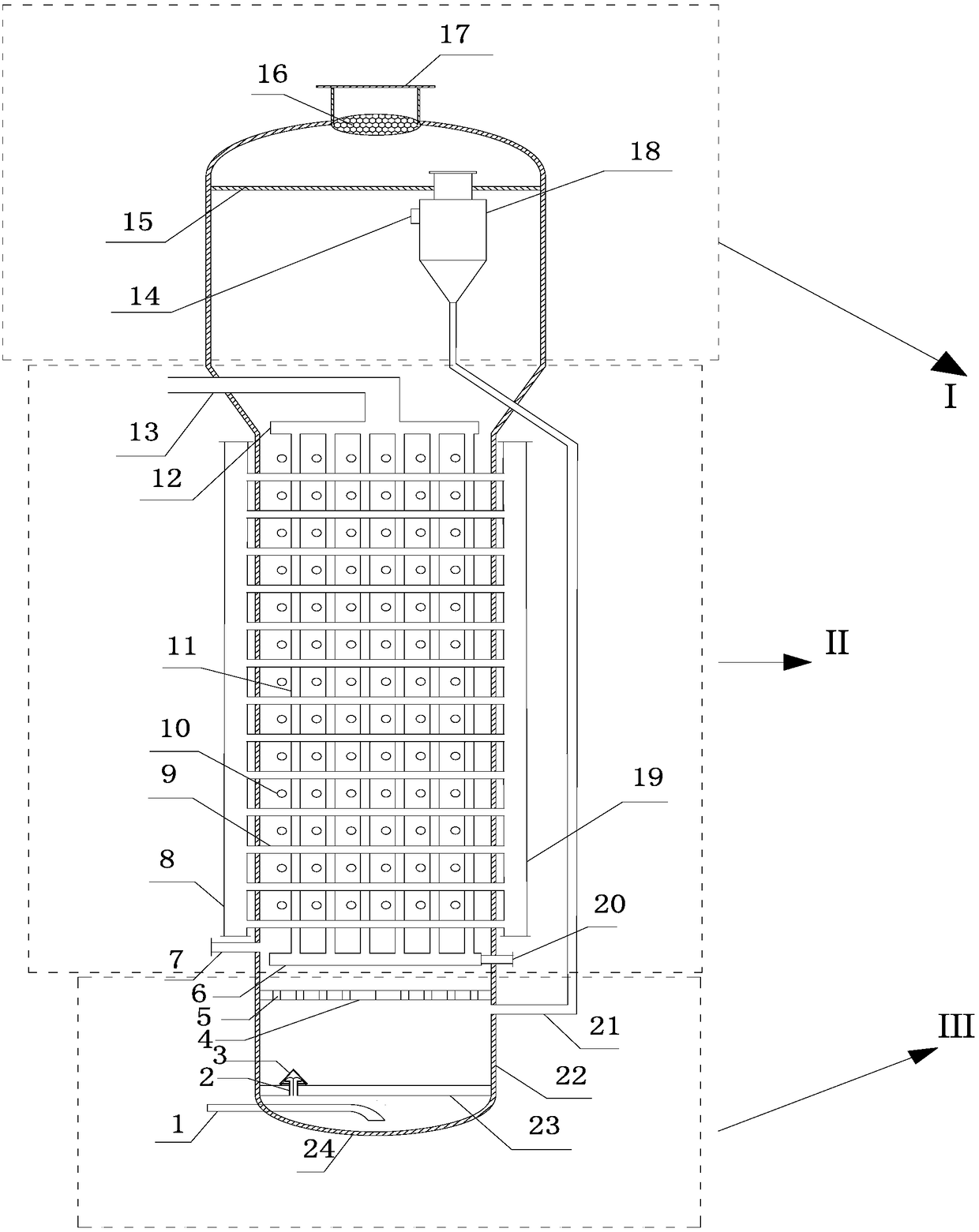

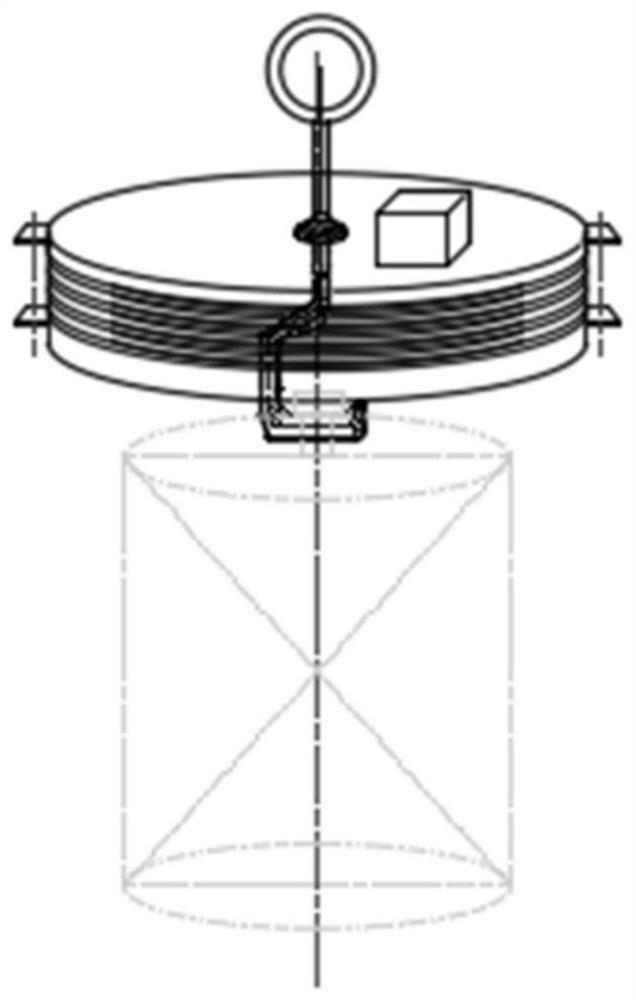

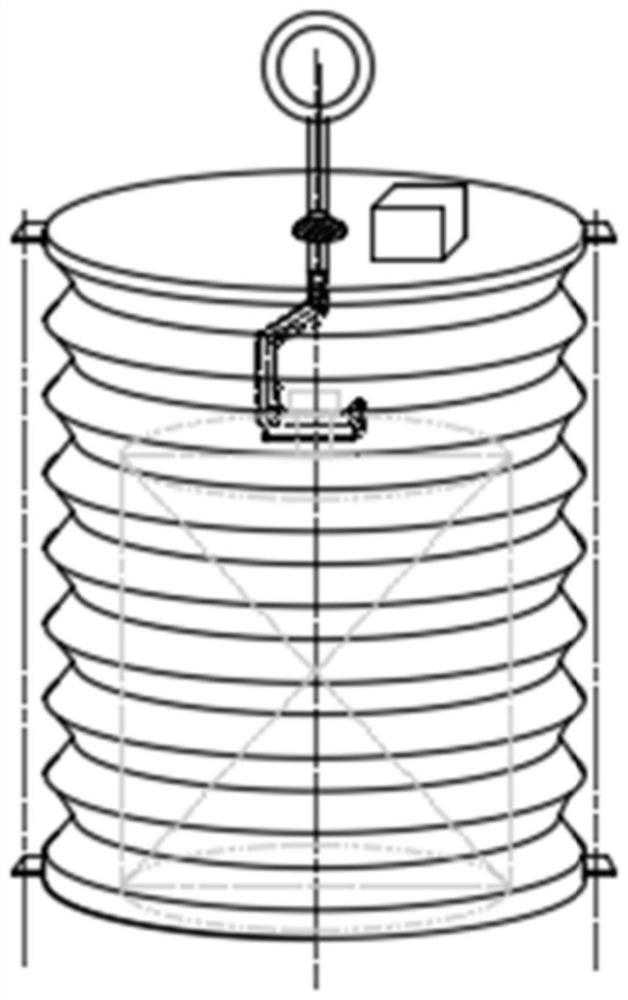

An intermittent fluidized thermal energy and chemical energy storage and release reaction device and working method

InactiveCN105841537BAvoid cakingAvoid reactionHeat storage plantsFluidised bed heat exchangersThermal energyGas solid

Owner:SOUTH CHINA UNIV OF TECH

Burley tobacco processing, alcoholizing and blending method

The invention discloses a burley tobacco processing, alcoholizing and blending method. The method includes the steps of firstly, weighing, by weight, 80 parts to 120 parts of threshed and redried burley tobacco strips, 100 parts to 150 parts of water and 2.5 parts to 3.5 parts of fresh flowers for standby application, fully soaking the burley tobacco strips in the water, subpackaging the fresh flowers through bags, and inserting the subpackaged fresh flowers into the burley tobacco strips; secondly, boiling the fresh flowers and the burley tobacco strips in boiled water for 5 minutes to 10 minutes, conducting cooling, then draining off water from the burley tobacco strips and the fresh flowers, curing the burley tobacco strips and the fresh flowers till the water content of the burley tobacco strips and the fresh flowers ranges from 12% to 13% after cooking and moisture regaining, alternately stacking and packaging the dried flowers and the burley tobacco strips in a layered mode, and conducting alcoholizing for 15 months to 18 months. The method is simple in operation process, easy to implement and capable of being easily converted into a production line; a water solution used in the processing process can be repeatedly utilized, no other chemical additives exist, and the industrial pollution is reduced.

Owner:HUBEI CHINA TOBACCO IND

CO2 decomposing method, CO2 decomposing system and application thereof

ActiveCN105905900AAchieve decompositionAchieve reuseSolidificationLiquefactionDecompositionEnergy consumption

The invention discloses a CO2 decomposing method, a CO2 decomposing system and application thereof. The CO2 decomposing method includes: putting CO2 in a radiation range of a radiation source so as to utilize ionizing radiation to decompose CO2 into CO and O2. By the CO2 decomposing method, CO2 decomposition can be realized effectively to obtain CO and O2 having industrial application value; besides, devices or materials releasing ionizing radiation are fully utilized, waste recycling is realized and equivalent to zero energy consumption, cost is low, and efficiency is high.

Owner:TSINGHUA UNIV

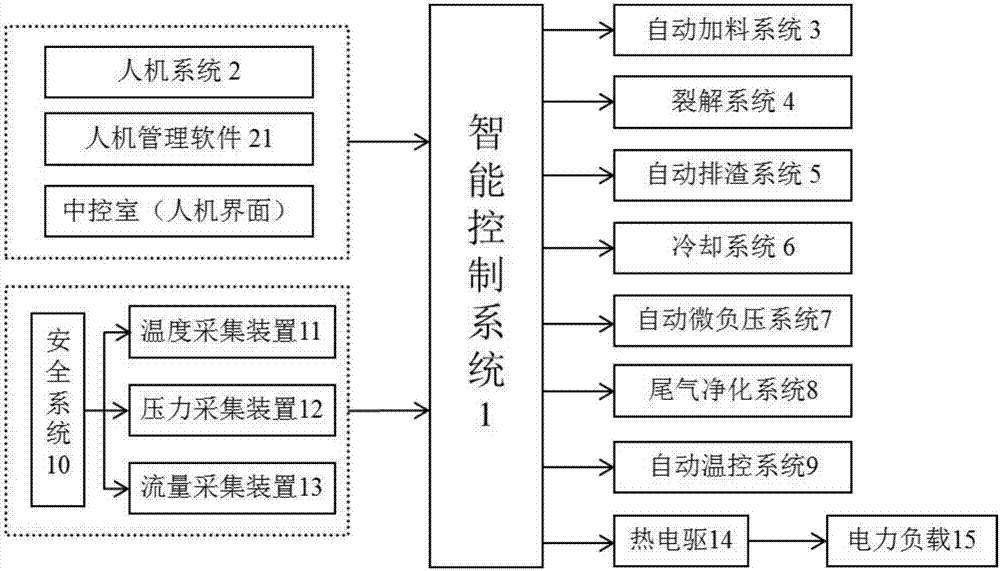

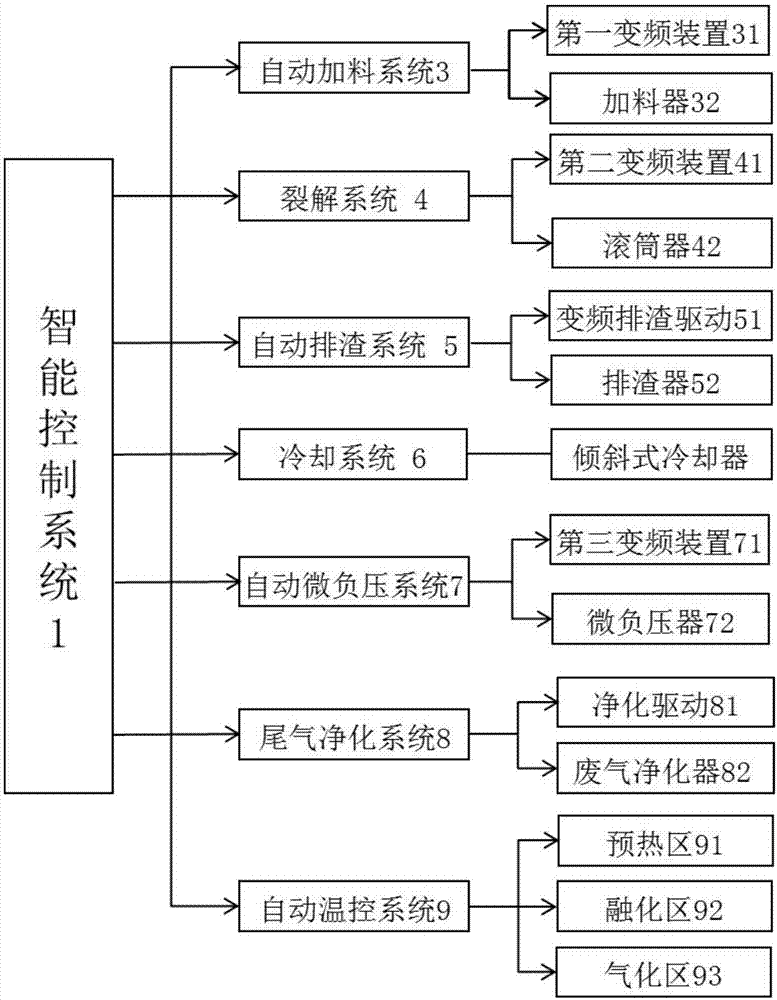

Intelligent acrylic cracking system

InactiveCN107463155AEasy to operateSpeed up circulationTotal factory controlProgramme total factory controlSlagProtection system

The invention relates to an intelligent acrylic cracking system, including an intelligent control system, the intelligent control system is respectively electrically connected to a man-machine system, an automatic feeding system, a cracking system, an automatic slag discharge system, a cooling system, an automatic micro-negative pressure system, and exhaust gas purification system, automatic temperature control system and safety system; the safety system cooperates with the intelligent control system to control other systems; the intelligent control system is a PLC processor; executes the operation instructions of the central control room, and automatically At the same time, it takes into account the safety system, emergency handling of failures, data analysis and other functions; the man-machine system is man-machine management software. The advantage of the present invention is that the acrylic cracking process is energy-saving, environment-friendly, and fully automated. At the same time, the intelligent control system combines with the safety protection system to detect the temperature, pressure, and flow, and realizes the alarm and elimination of automatic hidden dangers. On the basis of saving manpower and material resources, it greatly Improved cracking efficiency.

Owner:郭明发 +1

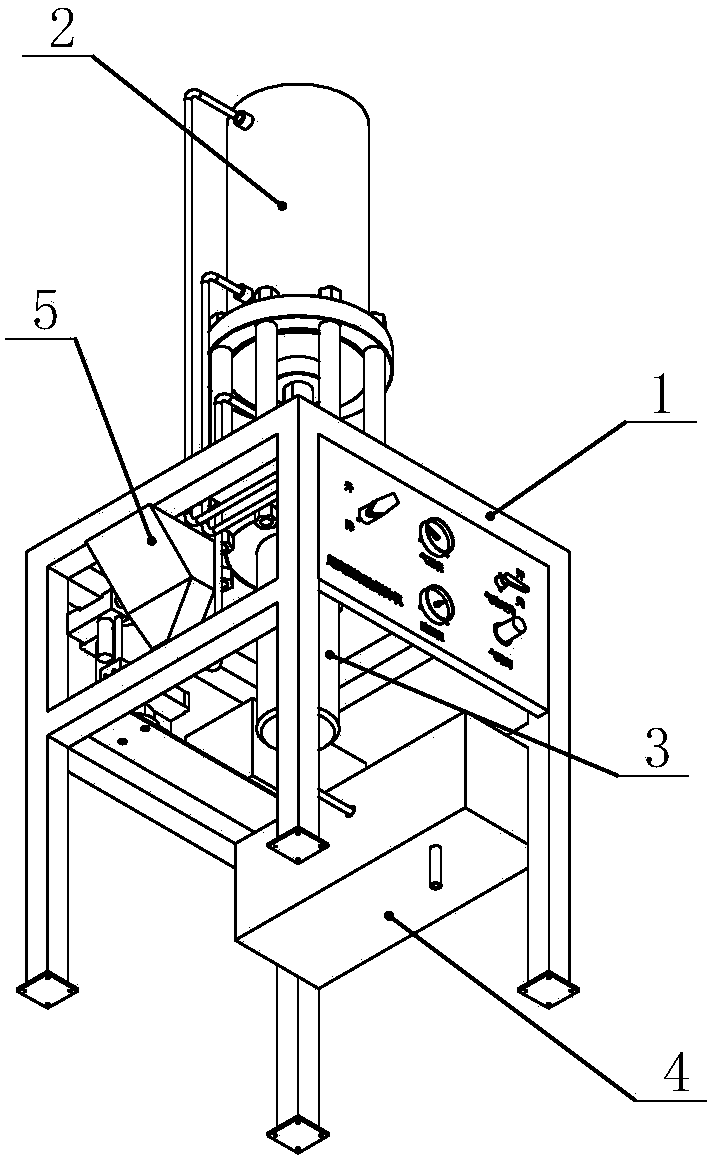

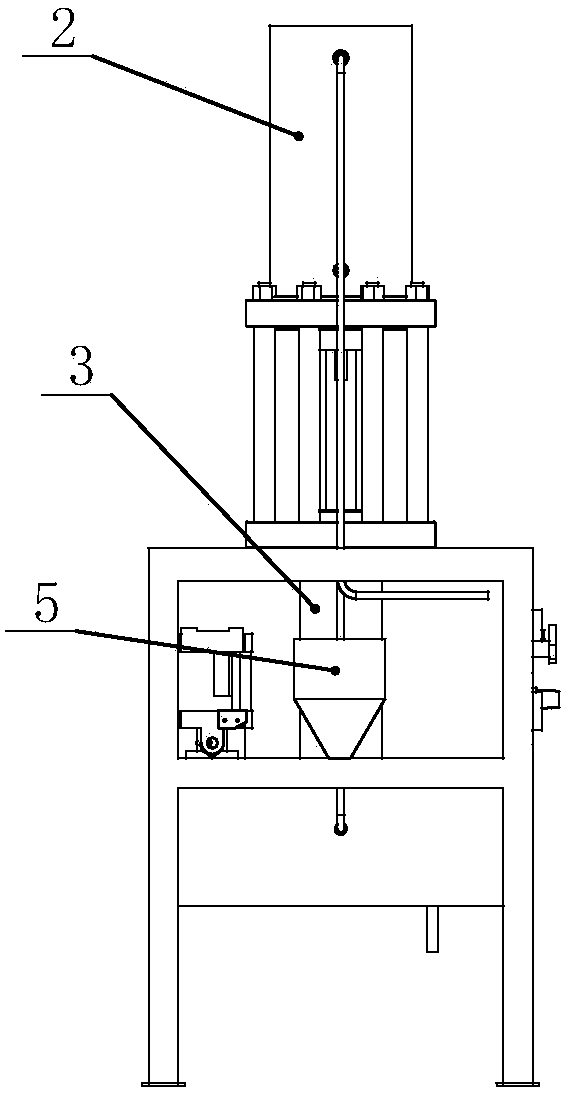

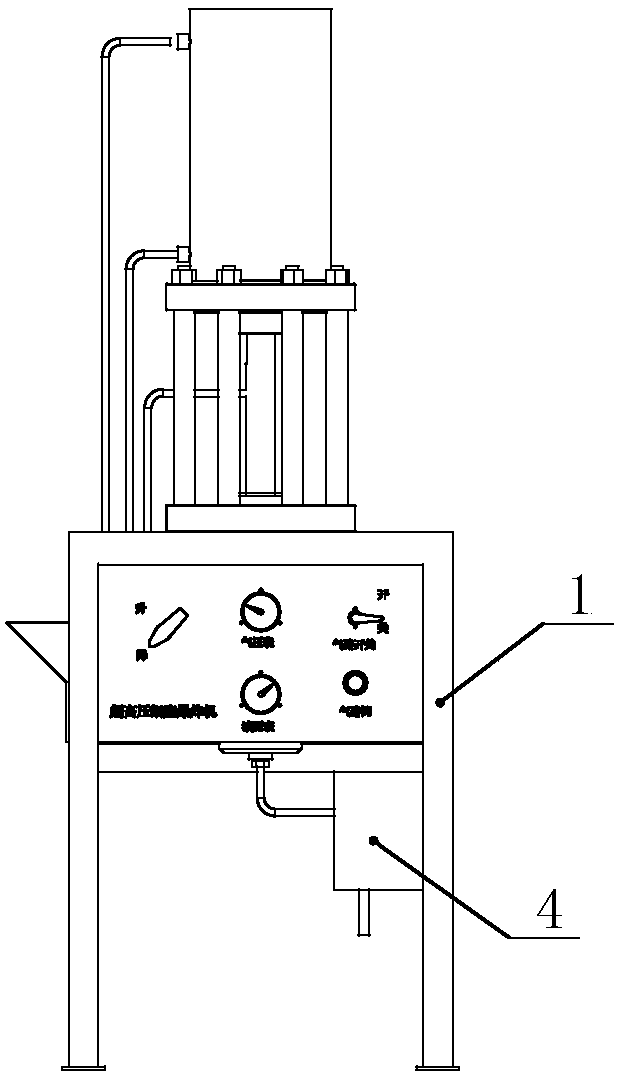

An industrial ultra-high pressure cell crushing method and a cell crushing machine

ActiveCN105925472BSwelling volumeIncrease internal hydraulic pressureMicroorganism lysisBiomass after-treatmentUltra high pressureHigh pressure

The invention discloses an industrial ultrahigh-pressure cell disruption method. According to the method, cells to be disrupted are subjected to volume two-stage expansion; then, the cells are disrupted by using a void effect and a shearing effect; the obviously expanded volume can enhance the disruption effects of the void effect and the shearing effect; the disruption effect better than the direct void effect and shearing effect cell disruption can be achieved, so that the cell tissues in biological medicine raw materials can be crushed; more than 97 percent of cell tissues can reach the value being less than 100nm; particles of target objects are uniform; the further extraction and purification are convenient; a great number of chemical reagents can be saved; the industrial pollution is reduced; and the utilization rate of medicine raw materials is greatly improved. The invention also discloses an industrial ultrahigh-pressure cell disruption machine, which comprises a support frame, a two-way hydraulic oil cylinder, an ultrahigh-pressure cavity, a recovery cavity, a check valve, at least one discharging valve, a feeding hopper, a pneumatic oil pump, an oil tank and a two-position four-way electromagnetic reversing valve.

Owner:LIAOCHENG WANHE IND MFR

Helical bevel gear driving tooth threading machining process

ActiveCN100581718CReduce industrial pollutionImprove processing efficiencyThread cutting machinesSolid state diffusion coatingGear wheelThermal insulation

Owner:ZHUZHOU GEAR CO LTD

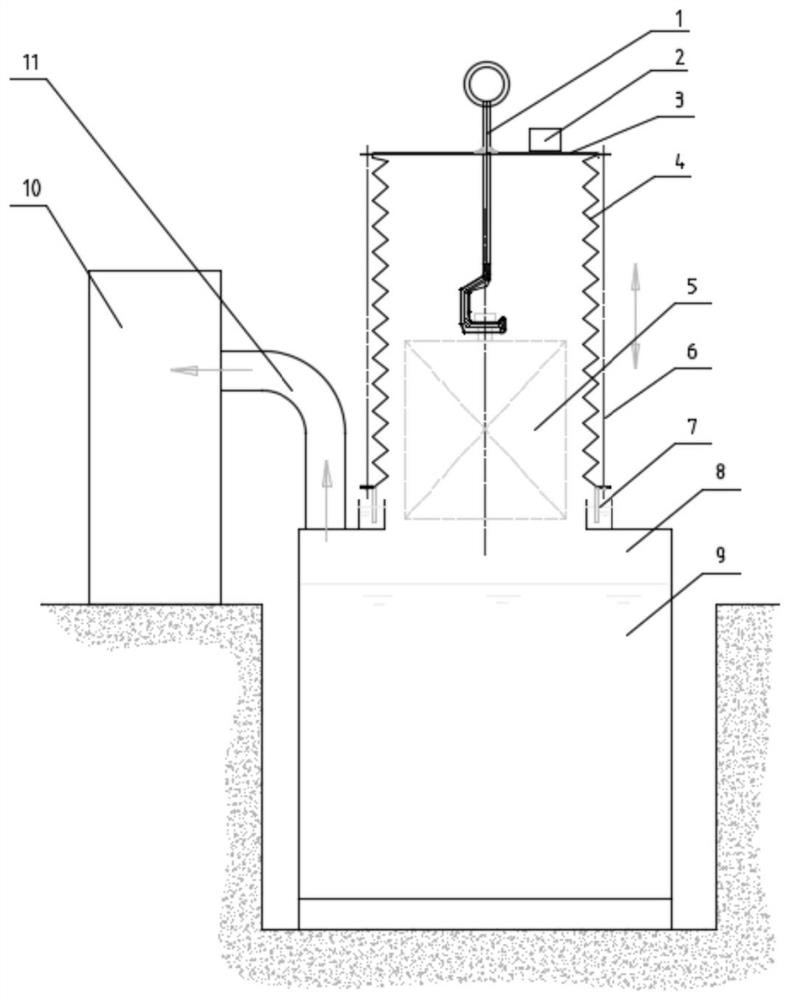

Fire extinguishing and smoke dust collecting device

PendingCN111876566AClosed QuenchingEfficient collectionDirt cleaningQuenching devicesEnvironmental engineeringWaste gas

The invention discloses a fire extinguishing and smoke dust collecting device comprising a telescopic section, a top cover, a grabbing device and a dust purifying device. A telescopic section is arranged on the lower surface of the top cover, is of a cylindrical structure and is coaxial with the top cover; the grabbing device is arranged on the top cover, and the grabbing end of the grabbing device is located in the telescopic section; and the top of a pit furnace quenching oil tank is connected with the dust purifying device. The device can effectively extinguish fire and collect smoke dust waste gas generated during quenching, the purpose of safe production is achieved, the collected smoke dust waste gas can be further purified subsequently, and the workshop environment is improved.

Owner:西安北恒材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com