Processing and manufacturing method of burley tobaccos

A processing method, the technology of burley tobacco, applied in the direction of processing tobacco, tobacco, application, etc., can solve the problems of excessive burley tobacco, heavy miscellaneous gas, strong irritation, etc., achieve easy grasp, low cost, and improve internal quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

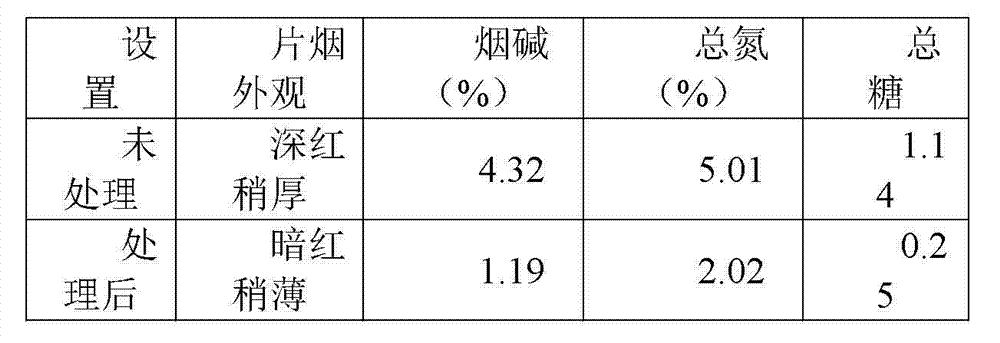

Image

Examples

Embodiment 1

[0011] Take Shangsan Burley tobacco from Enshi, Hubei Province (fermented for 20 months, the variety is Eyan No. 1), and soak it in an alcohol solution with a mass concentration of 70% at room temperature at 25°C for 25 minutes. Burley tobacco and Burley tobacco used for soaking The weight ratio of the alcohol solution is 1:2, the soaked Burley tobacco and the alcohol solution are ultrasonically treated at an ultrasonic frequency of 60kHz, an ultrasonic time of 50 minutes, and an ultrasonic temperature of 40°C. Distill for 15 minutes, drain the alcohol solution from the distilled Burley tobacco, and then dry it at 50°C until the moisture content is 11.5-13.5%.

[0012] The obtained burley tobacco leaves were cut into uniform shredded tobacco on a shredder, equilibrated at a temperature of 22±1°C and a humidity of 60±1% for 2 hours, and then rolled into cigarettes for evaluation and smoking.

[0013] The results of the sensory evaluation of the samples showed that the aroma cha...

Embodiment 2

[0014] Take Shangsan Burley tobacco from Enshi, Hubei Province (fermented for 20 months, the variety is Eyan No. 1), and soak it in an alcohol solution with a mass concentration of 80% at room temperature at 25°C for 15 minutes. The weight ratio of the alcohol solution is 1:3, the soaked Burley tobacco and the alcohol solution are ultrasonically treated at an ultrasonic frequency of 40kHz, an ultrasonic time of 30 minutes, and an ultrasonic temperature of 50°C. Distill for 10 minutes, drain the alcohol solution from the distilled Burley tobacco, and then dry it at 60°C until the moisture content is 11.5-13.5%.

[0015] The obtained burley tobacco leaves were cut into uniform shredded tobacco on a shredder, equilibrated at a temperature of 22±1°C and a humidity of 60±1% for 2 hours, and then rolled into cigarettes for evaluation and smoking.

[0016] The results of sensory evaluation and smoking evaluation of the samples showed that the obtained burley tobacco had sufficient ar...

Embodiment 3

[0018] Take Shangsan Burley tobacco from Enshi, Hubei Province (fermented for 20 months, the variety is Eyan No. 1), and soak it in an alcohol solution with a mass concentration of 90% at room temperature at 25°C for 5 minutes. Burley tobacco and Burley tobacco used for soaking The weight ratio of the alcohol solution is 1:6, and the soaked Burley tobacco and the alcohol solution are ultrasonically treated at an ultrasonic frequency of 20kHz, an ultrasonic time of 20 minutes, and an ultrasonic temperature of 60°C. Distill for 5 minutes, drain the alcohol solution from the distilled Burley tobacco, and then dry it at 70°C until the moisture content is 11.5-13.5%.

[0019] The obtained burley tobacco leaves were cut into uniform shredded tobacco on a shredder, equilibrated at a temperature of 22±1°C and a humidity of 60±1% for 2 hours, and then rolled into cigarettes for evaluation and smoking.

[0020] The results of sensory evaluation and smoking evaluation of the samples show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com