Supercritical (or subcritical) activation method for coal gangue and application of supercritical (or subcritical) activation method

A coal gangue and reaction technology, applied in the field of coal gangue activation, can solve the problems of large acid consumption, difficult operation, high acid concentration, etc., and achieve the effects of good environmental protection, simple reaction device, and low activation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

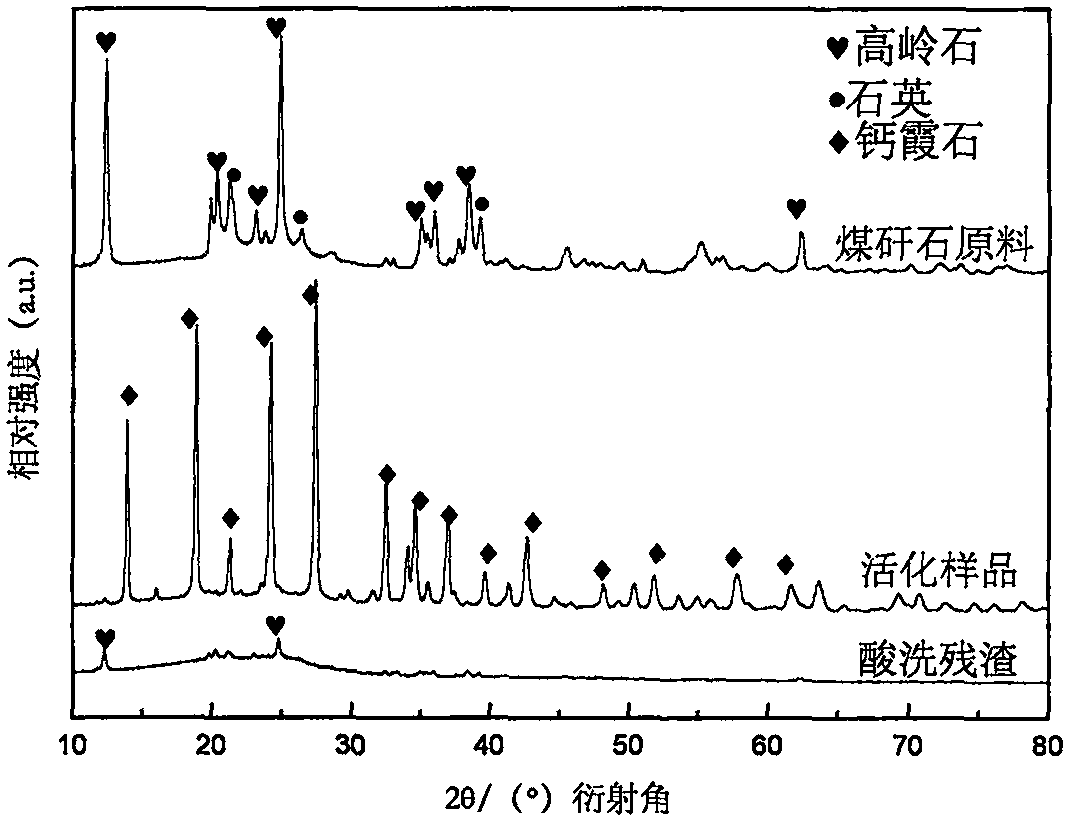

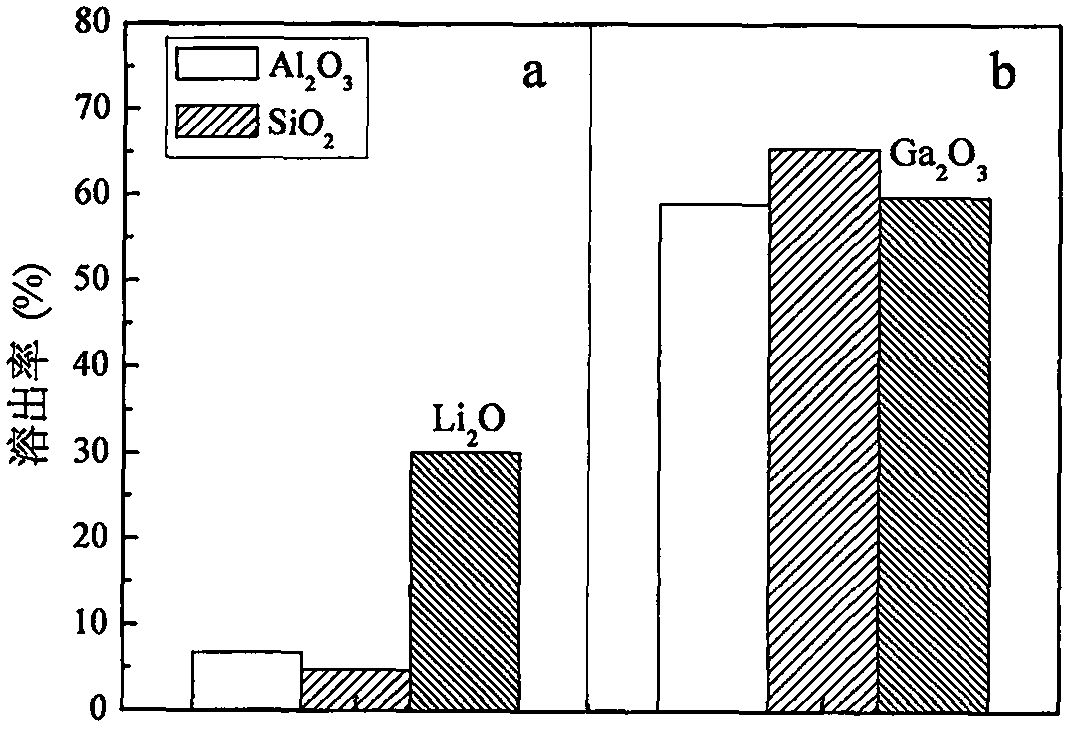

[0041] 1) Coal gangue activation: Accurately weigh Al 2 o 3 The content is 24.88% and SiO 2 The content is 10g of Pingshuo coal gangue of 32.40%, the configuration molar concentration is the NaOH aqueous solution of 2.0mol / L, the NaOH aqueous solution and the weighed coal gangue are mixed in a 50ml beaker according to the volume mass ratio of 10:1ml / g, room temperature Stir for 10 min. Then the stirred solution was moved to a reaction kettle, and reacted at 350° C. under supercritical conditions of 15 MPa for 10 minutes. The water was cooled to room temperature, filtered, washed, and the filter cake was dried at 110°C for 10 hours. And the filtrate obtained by solid-liquid separation and washing liquid are combined to obtain lithium-containing solution I;

[0042] 2) Acid leaching of aluminum, silicon, and gallium: the activated coal gangue sample was mixed with 1 mol / L hydrochloric acid according to the solid-to-liquid ratio of 1:10 g / ml, and reacted at room temperature f...

Embodiment 2

[0049] 1) Coal gangue activation: Accurately weigh Al 2 o 3 The content is 24.88% and SiO 2 20g of Pingshuo coal gangue with a content of 32.40%, and a NaOH aqueous solution with a molar concentration of 2.0mol / L, and the NaOH aqueous solution and the weighed coal gangue are mixed in a 50ml beaker at a volume-to-mass ratio of 20:1ml / g. Stir for 10 min. Then the stirred solution was moved to a reaction kettle, and reacted at 350° C. under supercritical conditions of 15 MPa for 10 minutes. The water was cooled to room temperature, filtered, washed, and the filter cake was dried at 110°C for 10 hours. And the filtrate obtained by solid-liquid separation and washing liquid are combined to obtain lithium-containing solution I;

[0050] 2) Acid leaching of aluminum, silicon, and gallium: the activated coal gangue sample was mixed with 1 mol / L hydrochloric acid according to the solid-to-liquid ratio of 1:10 g / ml, and reacted at room temperature for 7 hours to dissolve the reactan...

Embodiment 3

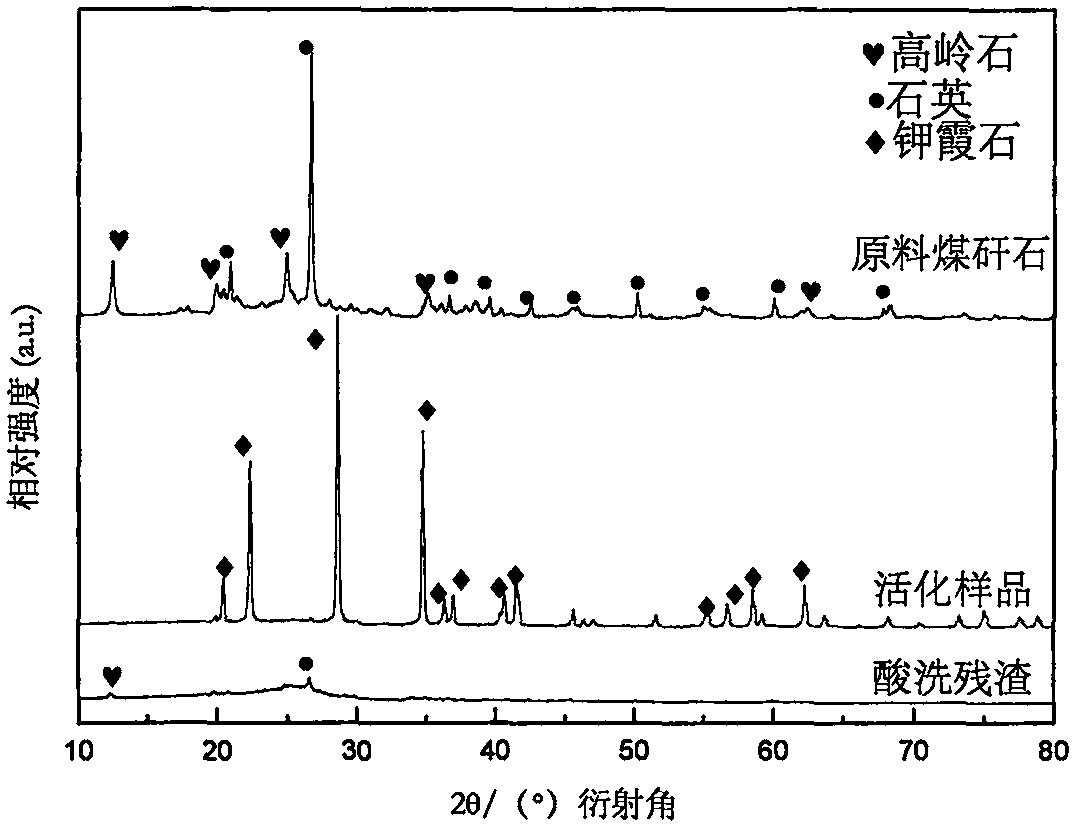

[0057] 1) Coal gangue activation: Accurately weigh Al 2 o 3 The content is 20.79% and SiO2 20g of Pingshuo coal gangue with a content of 31.85%, and a KOH aqueous solution with a molar concentration of 2.0mol / L, and the KOH aqueous solution and the weighed coal gangue are mixed in a 50ml beaker at a volume-to-mass ratio of 15:1ml / g. Stir for 10 min. Then the stirred solution was moved to a reaction kettle, and reacted at 250° C. under supercritical conditions of 3 MPa for 10 min. The water was cooled to room temperature, filtered, washed, and the filter cake was dried at 110°C for 10 hours. And the filtrate obtained by solid-liquid separation and washing liquid are combined to obtain lithium-containing solution I;

[0058] 2) Acid leaching of aluminum, silicon, and gallium: the activated coal gangue sample was mixed with 1 mol / L hydrochloric acid according to the solid-to-liquid ratio of 1:30 g / ml, and reacted at room temperature for 3 hours to dissolve the reactant, filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com