Method and system for preparing active coal gangue

A coal gangue and limestone technology, applied in the field of activated coal gangue preparation in the new dry cement production process, can solve the problems that the continuous production of calcined coal gangue cannot be guaranteed, achieve stable and reliable sources, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

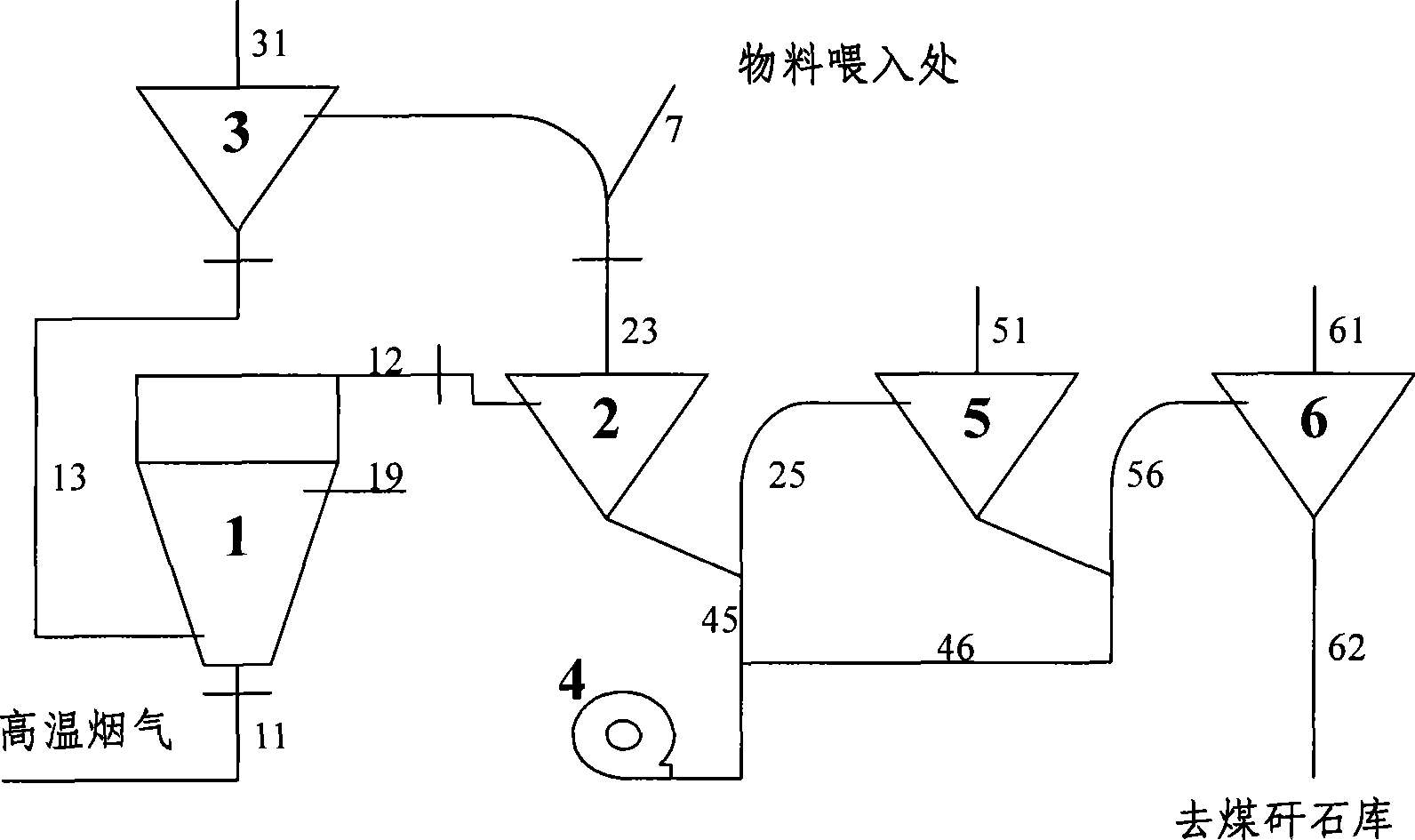

[0052] Embodiment one: the preparation of active coal gangue

[0053] The 80μm sieve residues of coal gangue and limestone were 13.9% and 11.5% respectively, and the mass fractions of particles smaller than 30μm were 67% and 74% respectively.

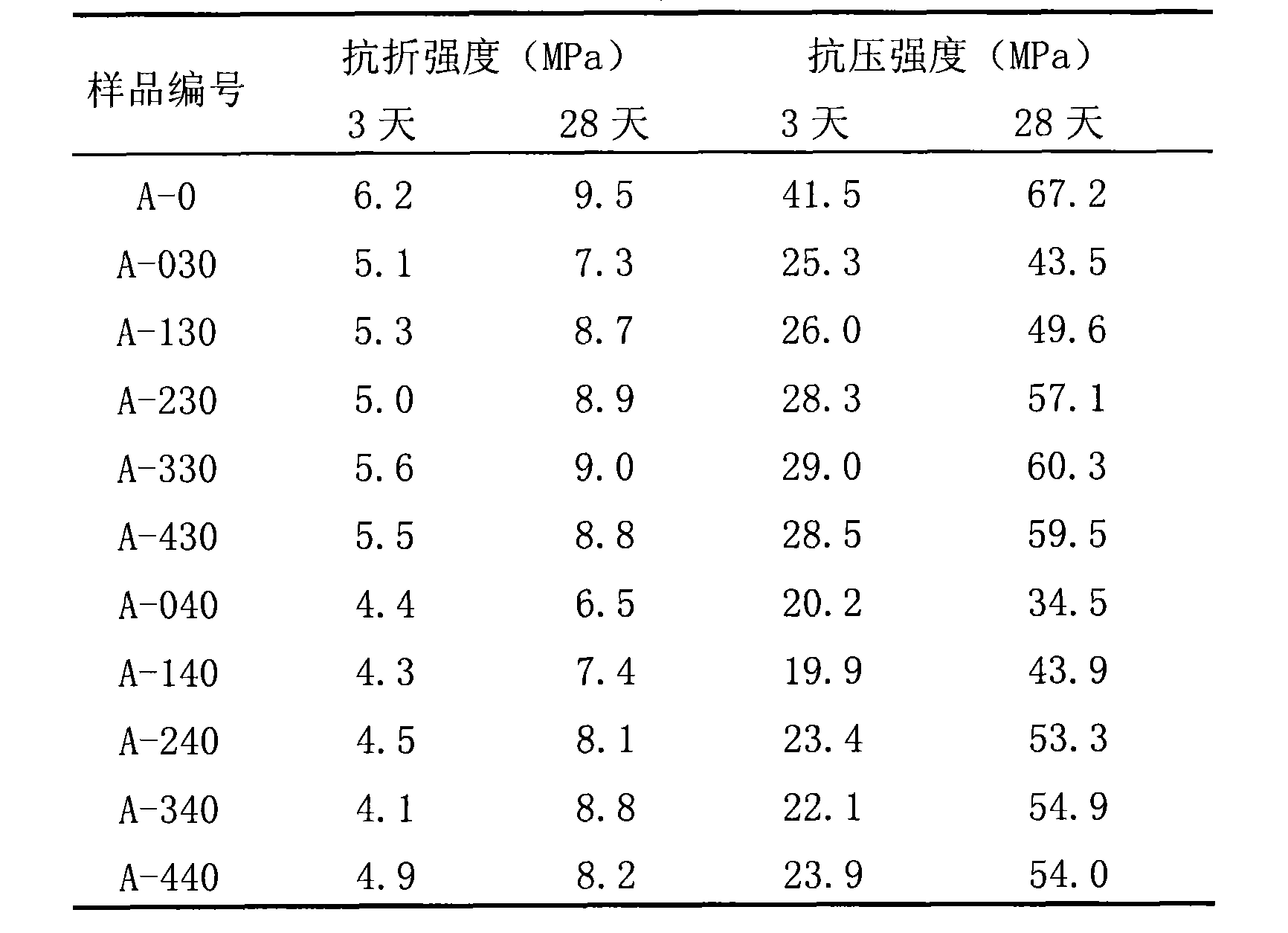

[0054] Introduce hot air with a temperature of about 900°C from the cooler of the new dry process kiln system, and feed coal in four batches according to the ratio of gangue to limestone: 100:0, 90:10, 70:30, and 50:50. Gangue calcination system, the activated powder obtained by preheating the preheating cyclone, calcining in the calcination furnace, and cooling step by step from the first to the third cyclone, respectively marked as A-1, A-2, A-3, A -4.

[0055] Wherein, the temperature of the material at the outlet of the preheating cyclone 3 is controlled to be about 400° C., and the temperature of the gas at the outlet is about 500° C. The outlet material temperature of coal gangue calciner 1 is about 850°C, and the outlet gas tem...

Embodiment 2

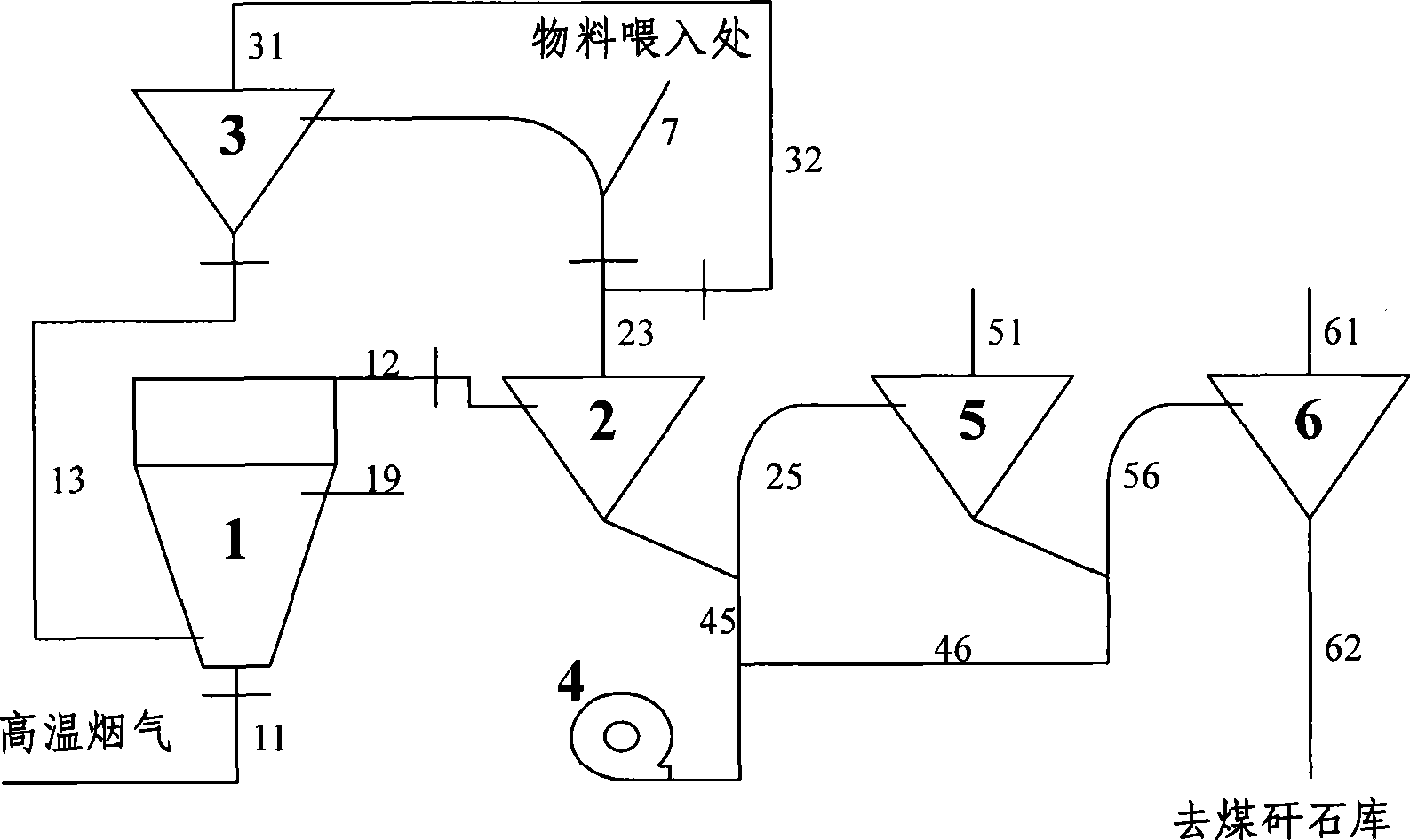

[0064] Example 2: Preparation of active coal gangue by circulating heat source

[0065] On the basis of Example 1, the waste gas from the calcination system was treated. The exhaust gas discharged from the preheating cyclone 3 has a higher temperature and a higher dust content, and the direct discharge not only wastes heat but also pollutes the environment. In order to make full use of this part of the heat, part of it is led back to the ascending pipe 23 through a pipe with an air flow valve, and the introduced waste gas is mixed with the gas from the first-stage cyclone to preheat the material together. In the embodiment, 50% of the high-temperature exhaust gas discharged from the waste gas channel 31 of the preheating cyclone 3 is led back to the pipeline 23. Although the air volume of the cyclone 3 is increased, the temperature of the outlet gas has little effect. After testing, the preheating cyclone 3 The outlet gas temperature is about 490°C. The temperature of the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com