Method for preparing aluminum oxide through treatment of coal ashes with hydrochloric acid

A technology of fly ash and alumina, which is applied in the direction of alumina/hydroxide, etc., can solve problems such as high cost, secondary pollution, and environmental pollution, and achieve the effect of easy equipment solution and favorable industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

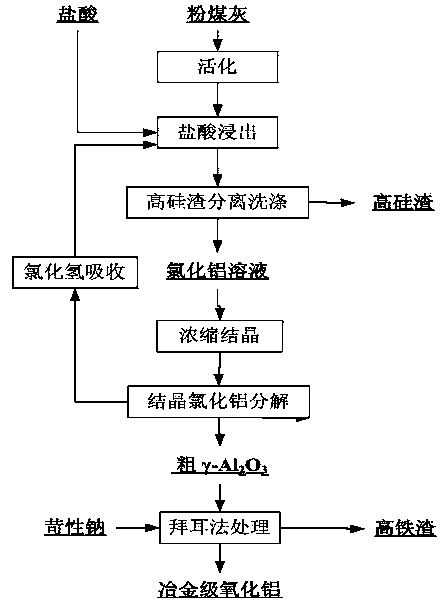

Image

Examples

Embodiment 1

[0020] Activate the fly ash mechanically, grind it to 800 mesh with a vibrating mill, and add 36% hydrochloric acid to the acid-resistant high-pressure reactor according to 1:6.5 (the molar ratio of the sum of alumina and iron oxide in fly ash to HCl in hydrochloric acid) Mix it with fly ash, the reactor is lined with acid-resistant tiles, heated to 160 ° C, the reaction time is 2 hours, the solid-liquid separation after the reaction cools down, and the aluminum chloride liquid is obtained, and the solid-liquid separation of the aluminum chloride solution and the high-silicon slag Using flocculation and sedimentation, the aluminum chloride liquid is spray-dried to obtain crystalline aluminum chloride, and the aluminum chloride crystal is decomposed at 400°C to obtain crude γ-Al 2 o 3 And hydrogen chloride gas, hydrogen chloride is absorbed by high silicon slag washing liquid to prepare hydrochloric acid, so as to realize the recycling of acid. Calcined crude γ-Al 2 o 3 Meta...

Embodiment 2

[0022] The raw material fly ash in Example 1 is mechanically activated, ground to 300 mesh in a vertical mill, and 25% hydrochloric acid is mixed according to the ratio of 1:7.5 (the sum of aluminum oxide and iron oxide in fly ash and the mole of HCl in hydrochloric acid ratio) into an acid-resistant high-pressure reactor and mix it with fly ash. The reactor is lined with enamel, heated to 190 ° C, and the reaction time is 3 hours. The solid-liquid separation of high-silicon slag adopts pressure filtration, and the aluminum chloride liquid is dried by drum to obtain crystalline aluminum chloride, and the aluminum chloride crystal is decomposed at 500°C to obtain crude γ-Al 2 o 3 And hydrogen chloride gas, hydrogen chloride is absorbed by water to prepare hydrochloric acid, so as to realize the recycling of acid. Calcined crude γ-Al 2 o 3 Metallurgical-grade alumina and high-iron slag that meet the standards are obtained through the Bayer process. High-silicon slag is used ...

Embodiment 3

[0024] Mechanically activate the raw coal fly ash in Example 1, use a planetary mill to grind to 100 mesh, and mix 15% hydrochloric acid at a ratio of 1:9 (the molar ratio of the sum of alumina and iron oxide in fly ash to HCl in hydrochloric acid) Add it into an acid-resistant high-pressure reactor and mix it with fly ash. The reactor is lined with glass, heated to 230 ° C, and the reaction time is 8 hours. The solid-liquid separation of slag adopts vacuum filtration, and the aluminum chloride liquid adopts multi-effect falling film evaporation to obtain crystalline aluminum chloride, and the aluminum chloride crystal is decomposed at 600°C to obtain crude γ-Al 2 o 3 And hydrogen chloride gas, hydrogen chloride is absorbed with dilute hydrochloric acid to prepare hydrochloric acid, so as to realize the recycling of acid. Calcined crude γ-Al 2 o 3 Metallurgical-grade alumina and high-iron slag that meet the standards are obtained through the Bayer process. High-silicon sla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com