Comprehensive utilization method of roasted gold concentrate

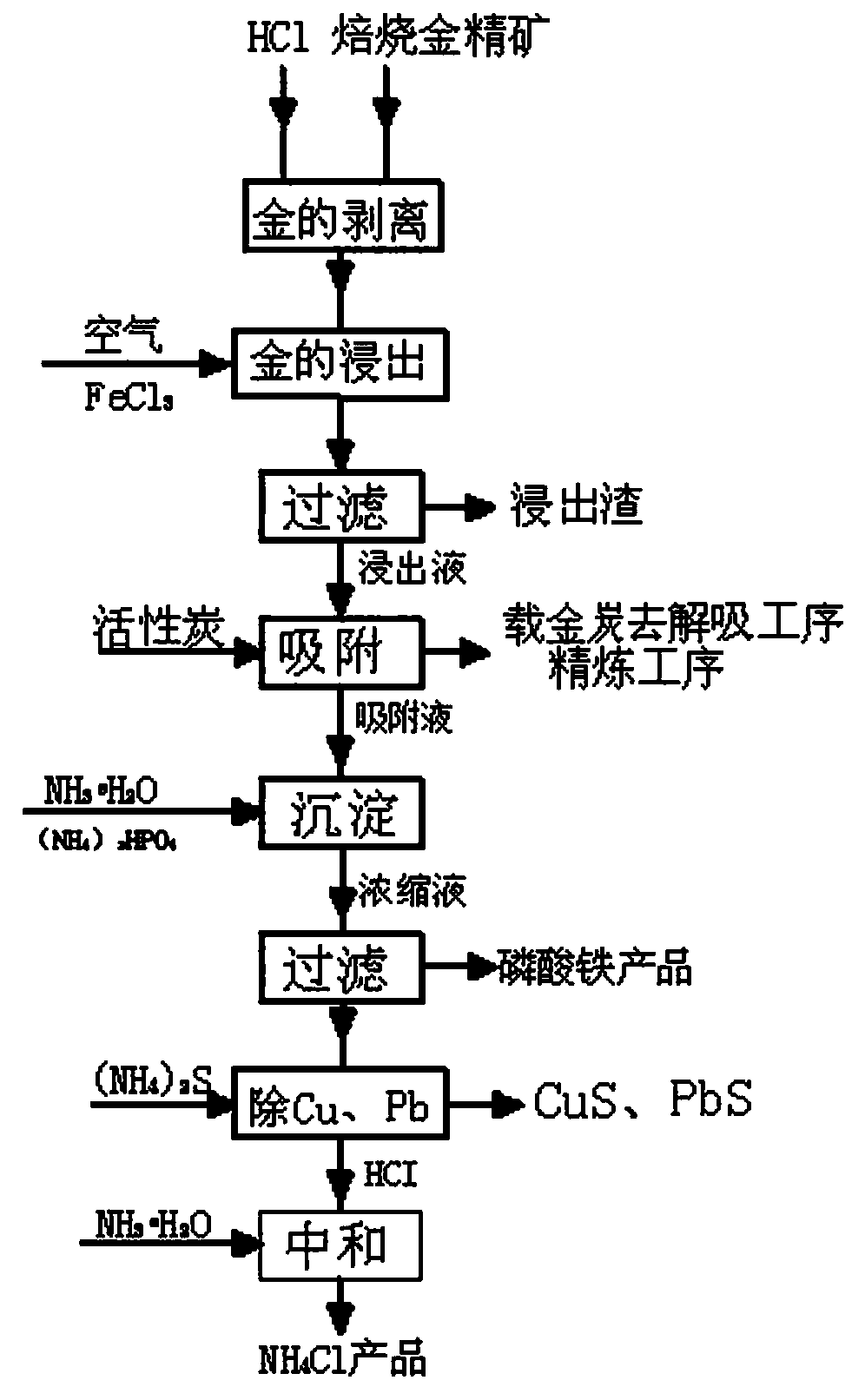

A gold concentrate and roasting technology, applied in chemical instruments and methods, phosphorus compounds, non-metallic elements, etc., can solve the problems of ineffective extraction, failure to comprehensively consider recycling and utilization, and multiple solid wastes, and achieve recycling rate. High, easy to operate, efficient extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Taking the roasted gold concentrate of a company in Xinjiang as an example, its composition: Fe: 19.92%, Au: 52.1g / t, S: 1.61%, Cu: 0.25%, Pb: 0.12%.

[0032] Weigh 10Kg of roasted gold concentrate and place it in a 50L reactor, add 20L of dilute hydrochloric acid (concentration: 6mol / L) according to the liquid-solid ratio of 2:1 (mL / g), stir, heat to 120°C, and react at a constant temperature 1.0h; after the reaction, measure Fe in the system 3+ , Fe 3+ The concentration is 1.6mol / L, the temperature is controlled at 50°C, the air is ventilated, and the reaction is continued for 2h, filtered, washed, the leached residue can be used for building materials, and the gold leaching rate is determined to be 98.9%; add 100g of activated carbon to the leaching solution, and control the temperature Below 35°C, stir and adsorb for 3 hours, filter, and the gold-loaded charcoal enters the desorption and refining process, and the recovery rate of gold is 99.5%; adjust the pH to 2.5...

Embodiment 2

[0034] Taking the roasted gold concentrate of a company in Sichuan as an example, its composition: Fe: 15.46%, Au: 30.3g / t, S: 1.12%, Cu: 0.24%, Pb: 0.13%.

[0035] Weigh 10Kg of roasted gold concentrate and place it in a 50L reactor, add 15L of dilute hydrochloric acid (concentration: 4.5mol / L) according to the liquid-solid ratio of 1.5:1 (mL / g), stir, heat to 100°C, and keep the temperature constant React for 0.75h; after the reaction, measure Fe in the system 3+ , Fe 3+ Concentration is 1.5mol / L, and temperature is controlled at 40 ℃, ventilates, continues reaction 1.5h, filters, washes, and leaching residue can be used for building material, and the leaching rate of measuring gold is 98.8%; Add 75g activated carbon in the leaching liquid, control The temperature is below 35°C, stirred and adsorbed for 2h, filtered, and the gold-loaded charcoal enters the desorption and refining process, and the recovery rate of gold is 99.3%; adjust the pH to 1.8 in the processing ammonia...

Embodiment 3

[0037] Taking the roasted gold concentrate of a company in Lingbao, Henan as an example, its composition: Fe: 12.35%, Au: 8.0g / t, S: 0.78%, Cu: 0.22%, Pb: 0.15%.

[0038] Weigh 10Kg of roasted gold concentrate and place it in a 50L reactor, add 10L of dilute hydrochloric acid (concentration: 3mol / L) according to the liquid-solid ratio of 1:1 (mL / g), stir, heat to 80°C, and react at constant temperature for 0.5h ; After the reaction, measure Fe in the system 3+ , Fe 3+Concentration is 0.98mol / L, add 0.843kg ferric chloride to adjust Fe 3+ Concentration is to 1.5mol / L, and temperature is controlled at 30 ℃, feeds air, continues reaction 1h, filters, washes, and leaching residue can be used for building material, and the leaching rate of measuring gold is 98.6%; Add 50g activated carbon in the leaching solution, control The temperature is below 35°C, stirred and adsorbed for 1h, filtered, and the gold-loaded charcoal enters the desorption and refining process, and the recovery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com