Ecological and environment-friendly high-count cotton yarn sizing method

A sizing method and an environmentally friendly technology, which is applied in the field of high-count cotton yarn sizing, can solve the problems of not developing an eco-friendly sizing formula, and achieve the effects of easy popularization and application, low equipment investment and operating costs, and excellent sizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

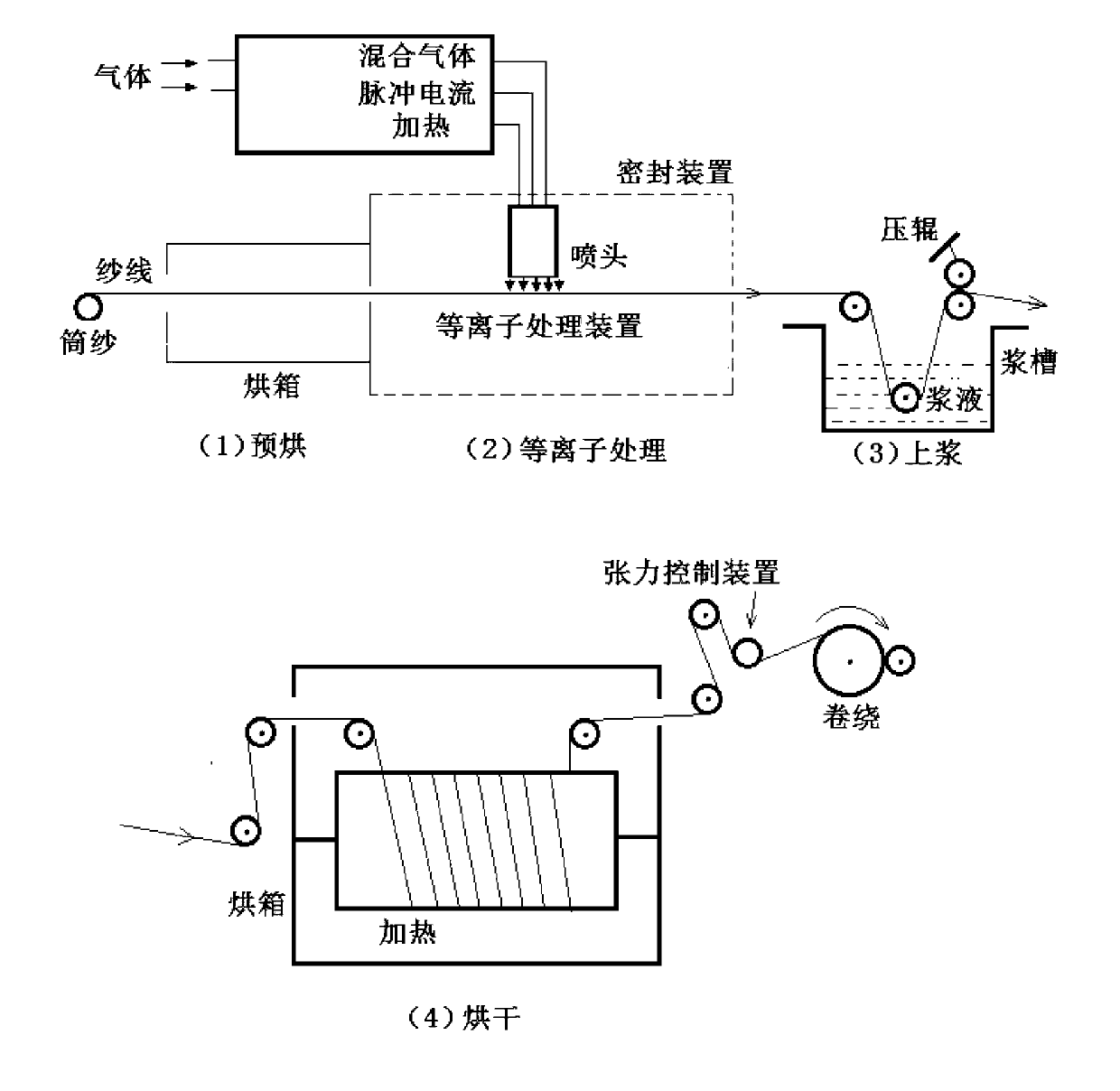

[0030] (1) After the 60-count pure cotton combed yarn is pre-dried by the pre-drying device, its moisture regain reaches 3.0%.

[0031] (2) After the yarn is dried by the pre-drying device, it enters the plasma treatment area directly through the closed channel.

[0032](3) The radio frequency of plasma treatment is 13.56 MHz; the volume flow ratio of helium and oxygen is 100:1; the treatment time is 12 seconds; the distance from the nozzle to the yarn is 1 mm; the treatment power is 40 watts. The processing method is continuous processing, and the yarn continuously passes under the plasma nozzle at a speed of 2 m / s.

[0033] (4) After the yarn is treated with plasma, it is sized with ecological size. The size formula is: 90% phosphate modified starch, 10% ethylene glycol; the solid content of the size is 7%, and the temperature of the size is 90°C. The sizing speed was 80 m / s, and the sizing tension was 100 cN.

[0034] (5) Setting of drying process parameters after sizing:...

Embodiment 2

[0036] (1) The moisture regain of the 60-count pure cotton combed yarn will reach 4.0% after pre-drying by the pre-drying device.

[0037] (2) After the yarn is dried by the pre-drying device, it enters the plasma treatment area directly through the closed channel.

[0038] (3) The radio frequency of plasma treatment is 13.56 MHz; the volume flow ratio of helium and oxygen is 100:1.5; the treatment time is 20 seconds; the distance from the nozzle to the yarn is 1.5 mm; the treatment power is 60 watts. The processing method is continuous processing, and the yarn continuously passes under the plasma nozzle at a speed of 2 m / s.

[0039] (4) After the yarn is treated with plasma, it is sized with ecological size. The size formula is: 80% corn starch, 20% ethylene glycol; the solid content of the size is 6%, the temperature of the size is 95°C, and the sizing speed is is 90 m / s, and the sizing tension is 110 cN.

[0040] (5) Setting of drying process parameters after sizing: dryi...

Embodiment 3

[0042] (1) After the 120-count pure cotton combed yarn is pre-dried by the pre-drying device, its moisture regain reaches 5.0%.

[0043] (2) After the yarn is dried by the pre-drying device, it enters the plasma treatment area directly through the closed channel.

[0044] (3) The radio frequency of plasma treatment is 13.56 MHz; the volume flow ratio of helium and oxygen is 100:2; the treatment time is 40 seconds; the distance from the nozzle to the yarn is 3.0 mm; the treatment power is 40 watts. The processing method is continuous processing, and the yarn continuously passes under the plasma nozzle at a speed of 1.5 m / s.

[0045] (4) After the yarn is treated with plasma, it is sized with ecological size. The size formula is: 85% wheat starch, 15% glycerol; the solid content of the size is 8%, the temperature of the size is 90°C, and the sizing speed is It is 70 m / s, and the sizing tension is 90 cN.

[0046] (5) Setting of drying process parameters after sizing: drying tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com