Powder material low temperature plasma surface treatment method and its apparatus

A technology of low-temperature plasma and powder materials, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physicochemical processes of energy application, etc., can solve the problem of low processing efficiency, poor processing uniformity, inaccessibility To achieve high processing efficiency, simple loading and unloading, and good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

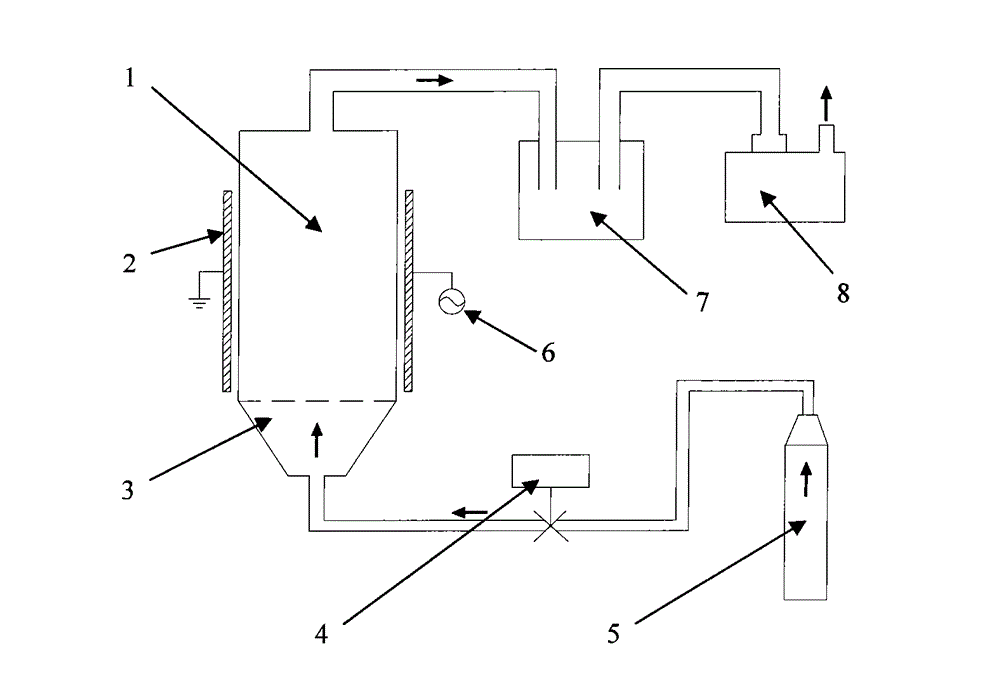

[0025] Example 1: Low-temperature plasma modification treatment on the surface of alumina powder

[0026] Weigh 200 grams of alumina powder (with a fineness of 20um), put it into the fluidized bed 3, and seal the fluidized bed 3. Vacuumize the fluidized bed 3 to 5 Pa, feed oxygen quantitatively at the bottom of the fluidized bed to keep the alumina powder in a fluidized state, and maintain the vacuum in the fluidized bed 3 at 100 Pa. Turn on the high-frequency power supply, apply a high-frequency electric field to the fluidized bed 3, form plasma in the fluidized bed 3, maintain a discharge power of 100W, and stop vacuuming and gas feeding after 10 minutes of treatment time. Fill the fluidized bed 3 with pure air to make the internal and external pressures of the fluidized bed 3 equal. At this time, open the outlet of the fluidized bed 3, take out the processed materials, and the treatment is over.

Embodiment 2

[0027] Example 2: Low-temperature plasma modification treatment on the surface of silica powder

[0028] Weigh 200 grams of silicon dioxide powder (fineness is 10um), put it into the fluidized bed 3, and seal the fluidized bed 3. Vacuumize the fluidized bed 3 to 5 Pa, feed oxygen quantitatively at the bottom of the fluidized bed 3, make the silica powder in a fluidized state, and maintain the vacuum degree in the fluidized bed 3 at 100 Pa. Turn on the high-frequency power supply, apply a high-frequency electric field to the fluidized bed 3, form plasma in the fluidized bed 3, maintain a discharge power of 100W, and stop vacuuming and gas feeding after 10 minutes of treatment time. Fill the fluidized bed 3 with pure air to make the pressure inside and outside the fluidized bed 3 equal. At this time, open the outlet of the fluidized bed 3 to take out the processed materials, and the treatment is over.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com