Method and device for high-efficiently and quickly oxidizing and fixing arsenic in wastewater based on glow discharge

A glow discharge and water treatment device technology, which is applied in the field of environmental sewage treatment, can solve problems that have not received full attention from everyone, and achieve the effect of efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A treatment method for efficiently and rapidly oxidizing and fixing arsenic in waste water by using glow discharge, comprising the following steps:

[0030] (1) Adjust the pH value of the wastewater solution containing As (III) to be treated to 3 and the conductivity value to 6 mS / cm, and adjust the concentration of Fe(II) in the wastewater solution so that Fe(II) / As( III) the molar ratio is 2, and it is imported into the electrode glow discharge water treatment device;

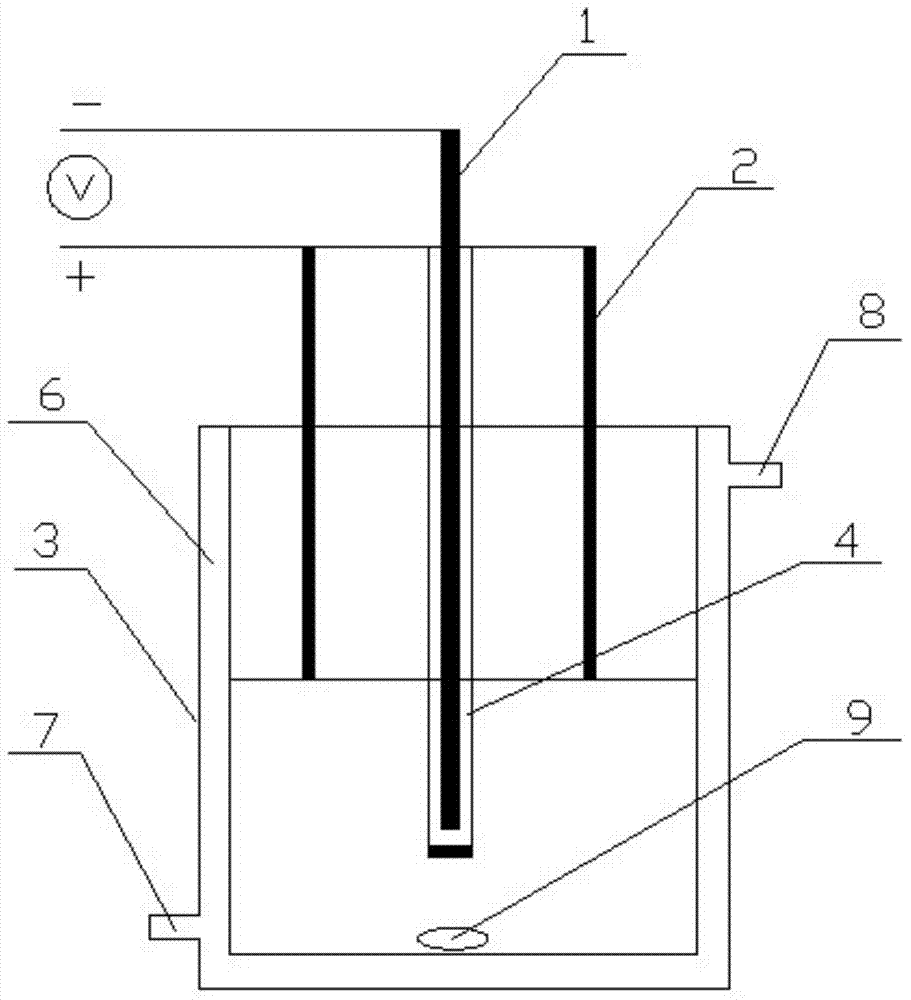

[0031] (2) The glow discharge reactor described as figure 1 As shown, 4 needle electrodes are used as stainless steel anodes, and the cathode is a carbon rod electrode, which is isolated from the solution through a glass tube with a sealed sand core at the bottom. When discharging, each needle electrode is in contact with the liquid surface. The normal working DC voltage is 480V, the current is 80mA, the discharge is in the atmosphere, and the stirring rate is 2 revolutions / s; after the discharge trea...

Embodiment 2

[0033] A treatment method for efficiently and rapidly oxidizing and fixing arsenic in waste water by using glow discharge, comprising the following steps:

[0034] (1) Adjust the pH value of the wastewater solution containing As (III) to be treated to 6 and the conductivity value to 1 mS / cm, and adjust the concentration of Fe(II) in the wastewater solution so that Fe(II) / As( III) the molar ratio is 4, which is imported into the electrode glow discharge water treatment device;

[0035] (2) In the glow discharge reactor, two needle electrodes are used as stainless steel anodes, and the cathode is a carbon rod electrode, which is isolated from the solution through a glass tube with a sand core sealed at the bottom. When discharging, each needle electrode is connected to the liquid surface In contact with each other, the normal working DC voltage is 1000V, the current is 500mA, the discharge is in the atmosphere, and the stirring rate is 2 revolutions / s; after the discharge treatm...

Embodiment 3

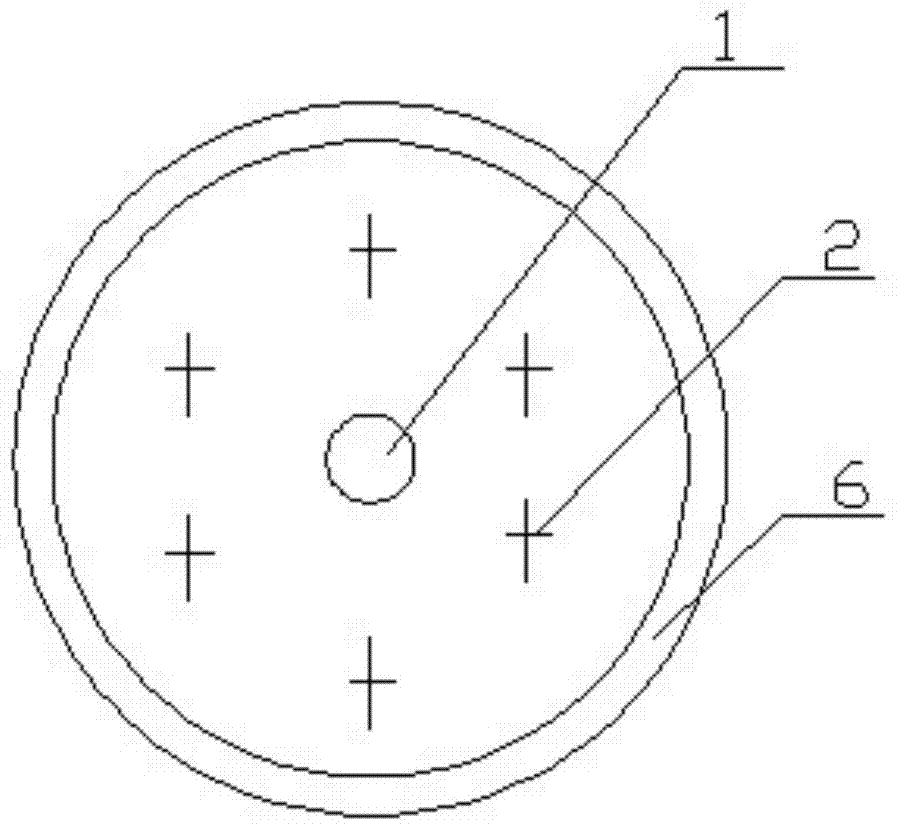

[0037] Such as figure 1 with figure 2 As shown, an electrode glow discharge water treatment device includes a carbon rod cathode (1), a stainless steel anode (2), a glass reactor (3), a glass tube (4), the carbon rod cathode (1) and a glass The tubes (4) are respectively arranged on the upper cover of the glass reactor (3); the outer periphery of the glass reactor (3) is provided with a cold hydrazine interlayer (6), and the cold hydrazine interlayer (6) is respectively provided with a cooling inlet A water port (7) and a cooling water outlet (8); the bottom of the glass tube (4) is sealed with a quartz sand core, and the stainless steel anode (2) is placed in the glass tube (4).

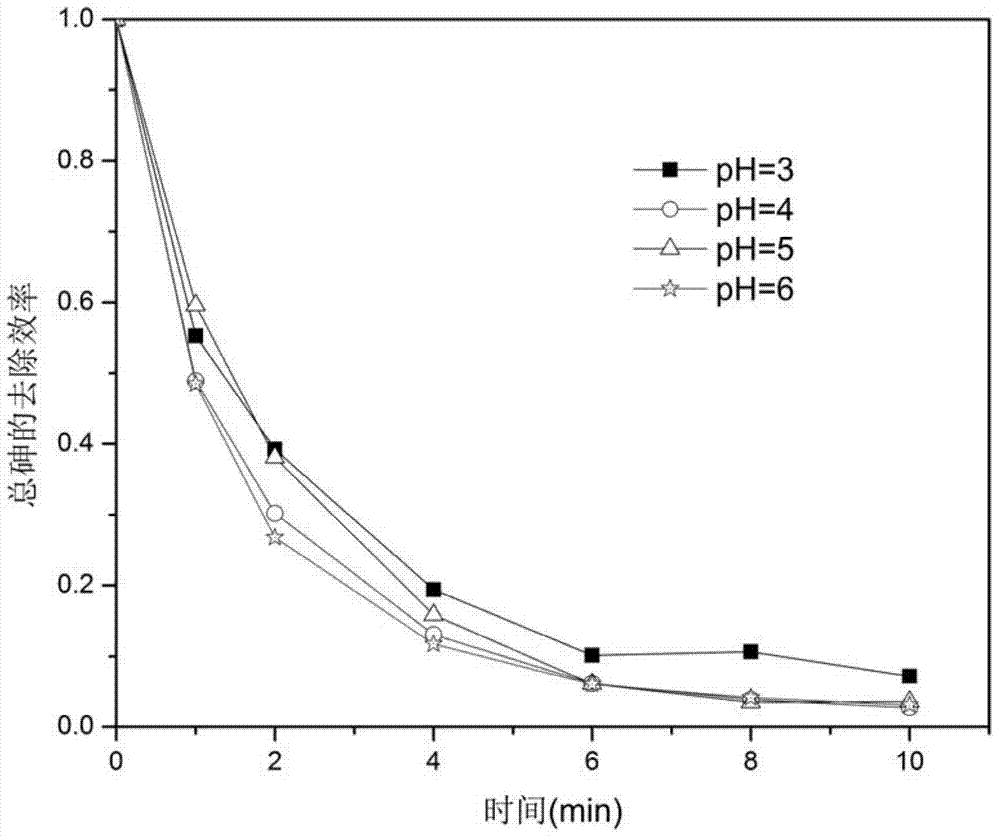

[0038] Prepare the solution to be treated: 250mL of mixed solution with As(III) concentration of 0.8mM and Fe(II) concentration of 1.6mM, use sodium sulfate to adjust the conductivity of the solution to about 3.0mS / cm, and use sulfuric acid to adjust the pH value to 3 , 4, 5, and 6 four kinds of so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com