Preparation apparatus and preparation method for graphene

A preparation device, graphene technology, applied in the direction of graphene, bulk chemical production, nano-carbon, etc., can solve the problems of difficult to prepare high-quality graphene, cumbersome mechanical exfoliation method, unfavorable industrial implementation, etc., to achieve exfoliation High efficiency, continuous production, and less defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

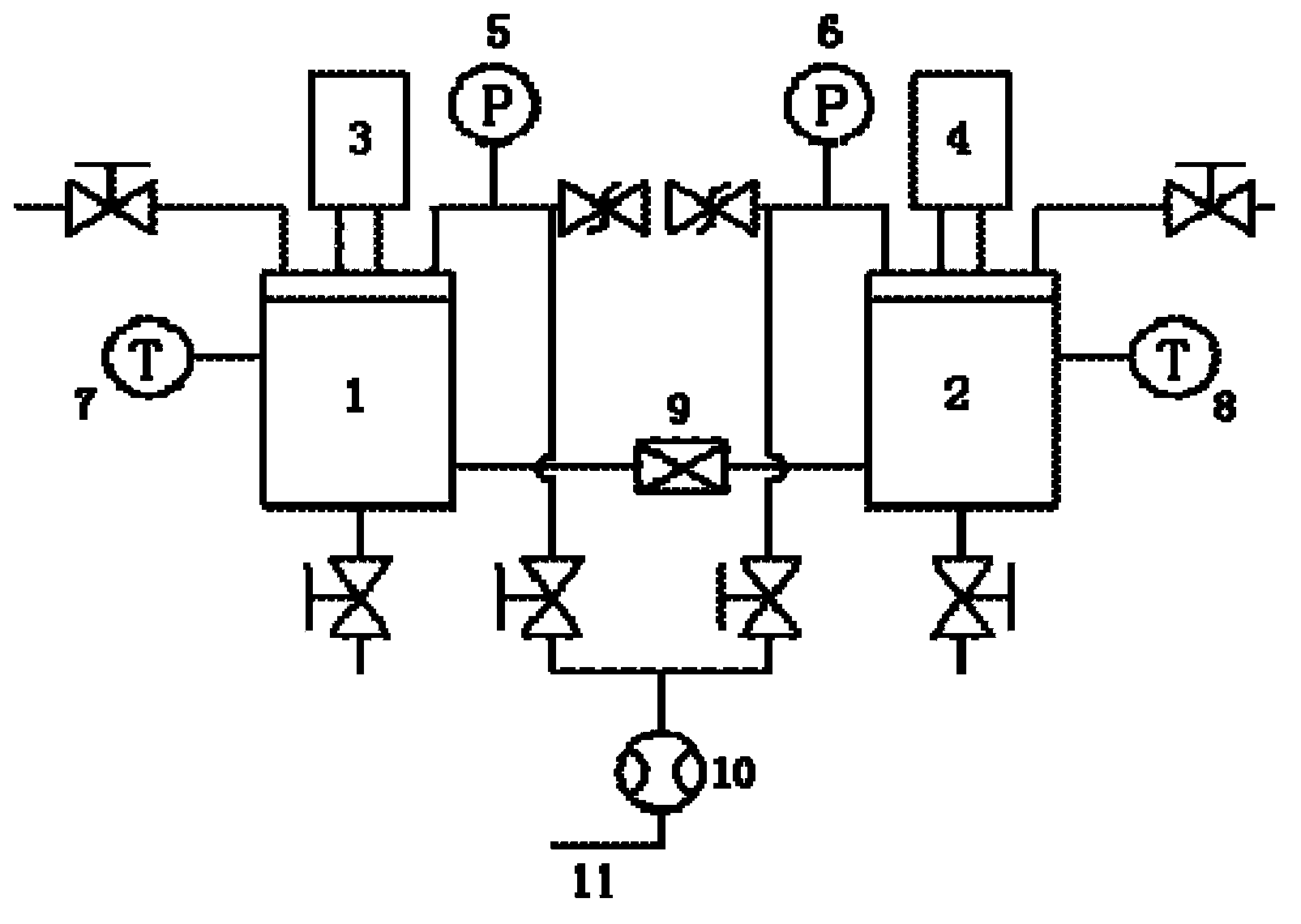

[0046] The present embodiment provides a kind of preparation device of graphene, as figure 1 As shown, it at least includes: a first reactor 1, a second reactor 2, a first agitator 3, a second agitator 4, a first pressure gauge 5, a second pressure gauge 6, a first temperature controller 7, A second temperature controller 8, a pneumatic valve 9, a flow meter 10, a reaction medium inlet pipeline 11, other connecting pipelines and multiple valves;

[0047] The first reactor 1 is connected to the second reactor 2 through a pipeline, and the pneumatic valve 9 is arranged on the pipeline;

[0048] The first reactor 1 is connected with the first agitator 3;

[0049] The second reaction kettle 2 is connected with the second agitator 4;

[0050] The reaction medium inlet line 11 is bifurcated into two sections of pipelines respectively connected to the first reactor 1 and the second reactor 2, and the flow meter 10 is located at the front of the reaction medium inlet pipeline 11 bef...

Embodiment 2

[0056] The present embodiment provides a kind of preparation method of graphene, and it is the method that adopts the preparation device of the graphene of embodiment 1 to prepare, and this method comprises the following steps:

[0057] A, graphite powder is carried out ultrasonic cleaning, and the frequency of this ultrasonic cleaning is 40KHz, and power is 150W, and ultrasonic cleaning time is 5-10min, obtains the graphite powder after the purification;

[0058] B. Mix the purified graphite powder with sodium lauryl sulfate (dispersant) at a mass ratio of 1:5;

[0059] C, make the mixture of graphite powder and dispersant enter the first reactor 1, then open the first agitator 3;

[0060] D. Adjust the temperature in the first reactor 1 to 40°C (reaction temperature) and control it through the first temperature controller 7, and then feed carbon dioxide into the first reactor 1 through the reaction medium into the pipeline 11 (reaction medium, Its ratio with graphite powder...

Embodiment 3

[0067] The present embodiment provides a kind of preparation method of graphene, and it is the method that adopts the preparation device of the graphene of embodiment 1 to prepare, and this preparation method is basically the same as the preparation method of embodiment 2, and difference is: reaction medium is A mixture of carbon dioxide and nitrogen mixed at a mass ratio of 1:1; the mass ratio of graphite powder and sodium lauryl sulfate is 1:1; the reaction temperatures of the first reactor and the second reactor are both 40°C, The reaction pressure is 80 atmospheres, and the reaction time is 30 minutes; the number of cycles of graphite powder between the first reactor and the second reactor is 5 times.

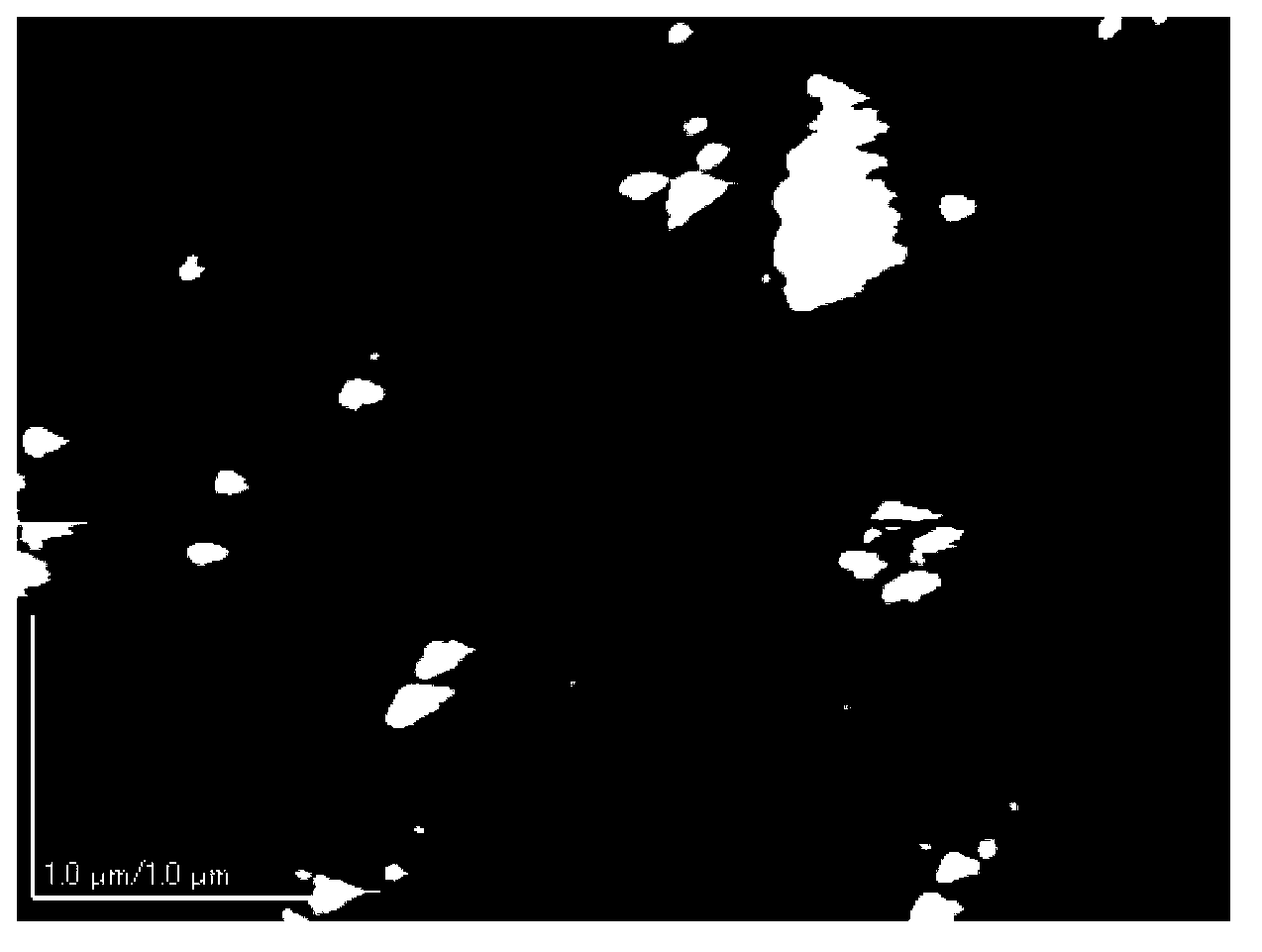

[0068] The obtained graphene product was characterized by atomic force electron microscope and transmission electron microscope, and its atomic force electron microscope photos are as follows: image 3 shown, according to image 3 And known method in the art calculates tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com