Continuous production equipment for foam aluminum alloy

A foamed aluminum alloy and production equipment technology, which is applied in the field of metal smelting equipment, can solve problems such as failure, small stirring force, and inability to realize quantitative input, so as to achieve the effect of improving product qualification rate and production efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

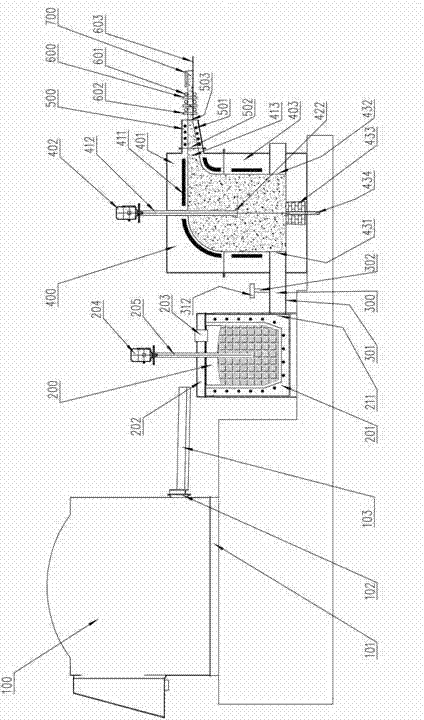

[0011] Such as figure 1 As shown, the present invention includes a smelting and holding furnace 100, a molten aluminum thickening furnace 200 and a continuous foaming furnace 400 arranged on the foundation, wherein the continuous foaming furnace 400 is connected with a roll device 600 for rolling foamed aluminum alloy profiles, and Cooling system 700 for cooling rolled and formed foamed aluminum alloy profiles, wherein:

[0012] The molten aluminum thickening furnace 200 includes an intermediate frequency furnace body 201, a movable furnace cover 202 and a stirring device. The intermediate frequency furnace body 201 receives the molten aluminum flowing out of the chute 103 of the smelting and holding furnace 100. The bottom of the intermediate frequency furnace body 201 is The delivery valve group 300 is arranged on the side to connect and deliver the thickened aluminum liquid to the continuous foaming furnace 400; the delivery valve group 300 includes a ceramic delivery pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com