Production method and device for continuous nano-fiber yarn

A nanofiber and production method technology, applied in the textile field, can solve problems such as poor yarn continuity, complex equipment, and poor uniformity, and achieve the effects of improved mechanical properties, convenient operation, and improved evenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

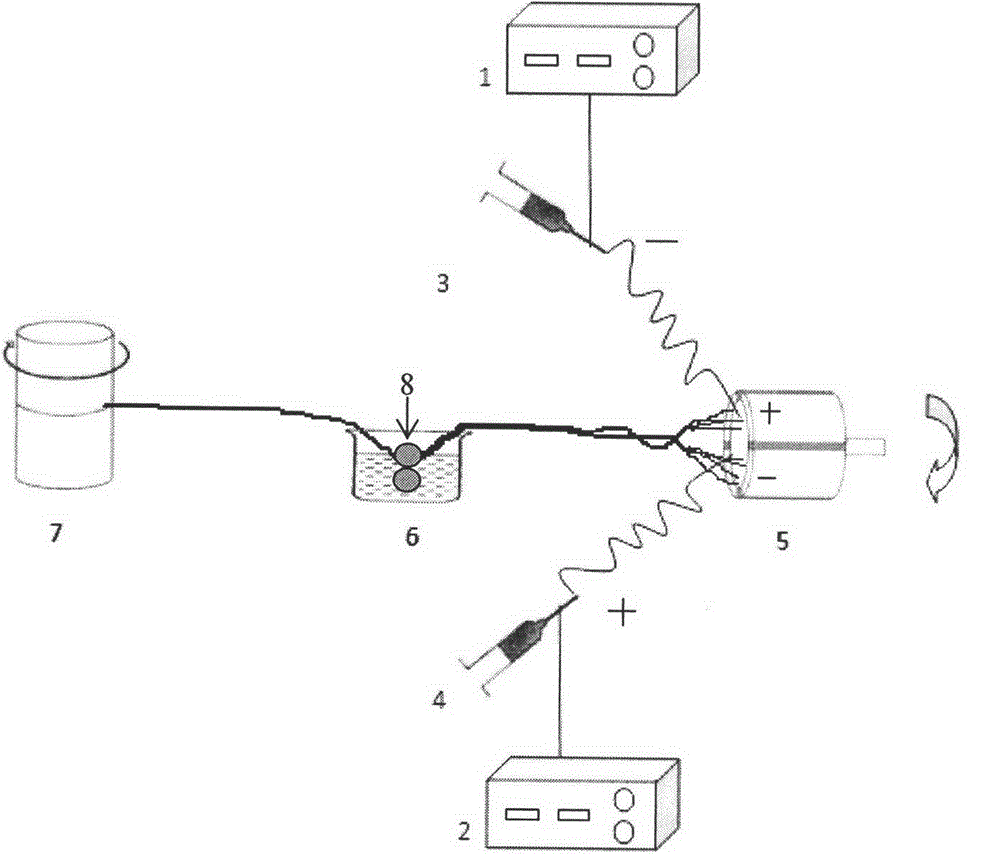

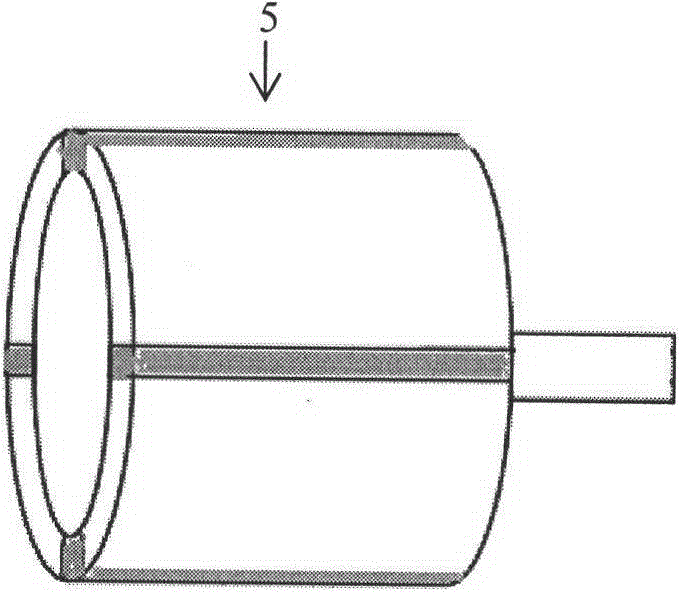

[0038] This embodiment relates to a production method and device for electrospinning continuous nanofiber yarn (see figure 1 ). Before spinning, weigh a certain amount of polyacrylonitrile (PAN, molecular weight: 80000g / mol) and dimethylformamide (DMF) to mix with 8% mass percent concentration, stir evenly at a temperature of 80°C, and statically Set for 2h to obtain PAN solution. When spinning, the prepared PAN solution was filled into syringes 3 and 4 for spinning, respectively. Then adjust the parameters so that the angle and distance between the two spinnerets are respectively 80° and 160mm, the vertical distance between the spinnerets and the plane of the rotating disk 5 is 70mm, and the distance between the rotating disk 5 and the winding device 7 is 450mm, and the distance between the rotating disk 5 The distance between the tank and the liquid tank 6 is 250mm, and the pressure roller 8 is housed in the liquid tank, and the hot water of 60 ℃ is filled in the liquid ta...

Embodiment 2

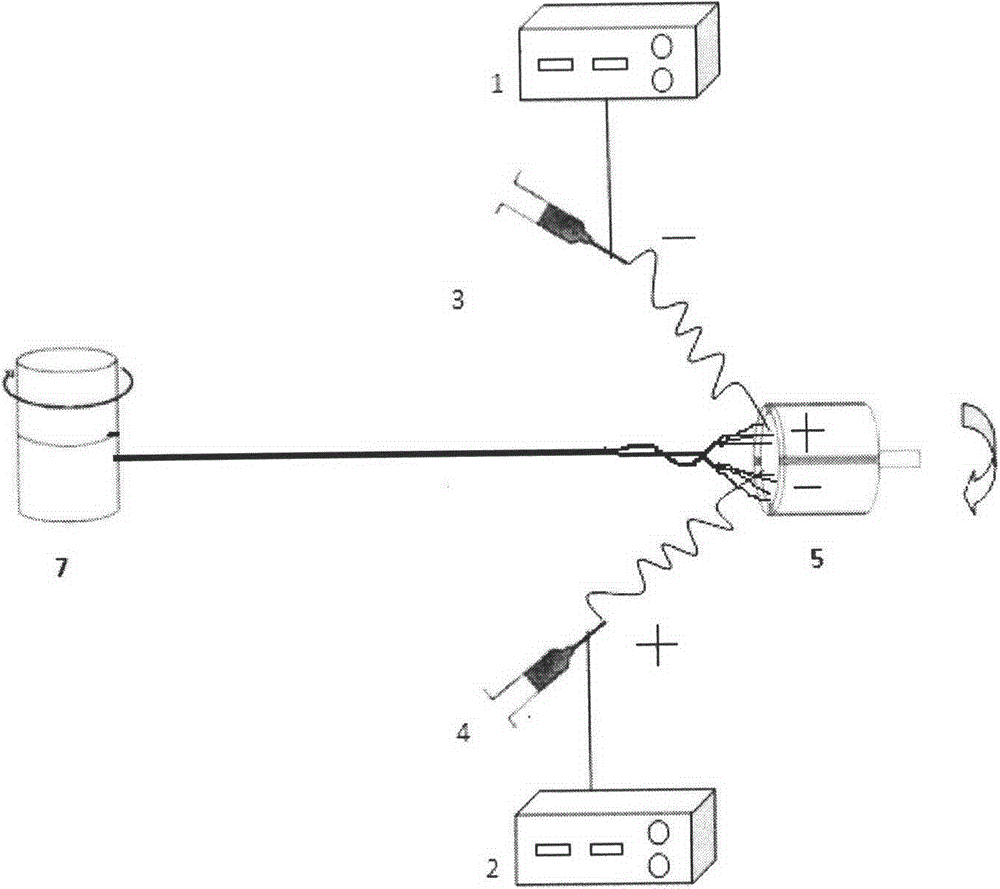

[0040] This embodiment relates to a production method and device for electrospinning continuous nanofiber yarn (see image 3 ). The difference from Embodiment 1 is that the liquid tank 6 and the pressure roller 8 are eliminated, and the coils are directly collected and wound to the winding device 7 . Before spinning, take a certain amount of polyvinyl alcohol (PVA, molecular weight is 3000g / mol) and solvent (ethanol and distilled water with 1: 1 mass ratio mixture) and mix with 16% mass percentage concentration, at 80 ℃ Stir evenly at high temperature and let it stand for 2 hours to obtain a PVA solution. When spinning, put the prepared PVA solution into syringes 3 and 4 for spinning. Then adjust the parameters so that the angle and distance between the two spinnerets are 100° and 160mm respectively, the vertical distance between the spinnerets and the plane of the rotating disk 5 is 80mm, and the distance between the rotating disk 5 and the winding device 7 is 450mm. The so...

Embodiment 3

[0042] This embodiment relates to a production method and device for electrospinning continuous nanofiber yarn (see Figure 4 ). The difference from Example 2 is that a filament of 0.5 m / min passes through the middle of the turntable as the core yarn. Before spinning, weigh a certain amount of polyacrylonitrile (PAN, molecular weight: 80000g / mol) and dimethylformamide (DMF) to mix with 8% mass percent concentration, stir evenly at a temperature of 80°C, and statically Set aside for 2 hours to obtain a PAN solution. When spinning, put the prepared PAN solution into syringes 3 and 4 for spinning. Then adjust the parameters so that the angle and distance between the two spinnerets are 100° and 160mm respectively, the vertical distance between the spinnerets and the plane of the rotating disk 5 is 80mm, and the distance between the rotating disk 5 and the winding device 7 is 450mm. The core yarn is 300D polypropylene filament, and the unwound polypropylene filament is wound to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com